Operating sound cancelling device for semi-active engine mount of vehicle

An engine bracket, semi-active technology, applied in the direction of valve operation/release device, power device, engine components, etc., can solve the problems of plunger valve shell or core impact noise, etc., to eliminate noise, reduce noise, Ensure the effect of shock absorption and damping function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

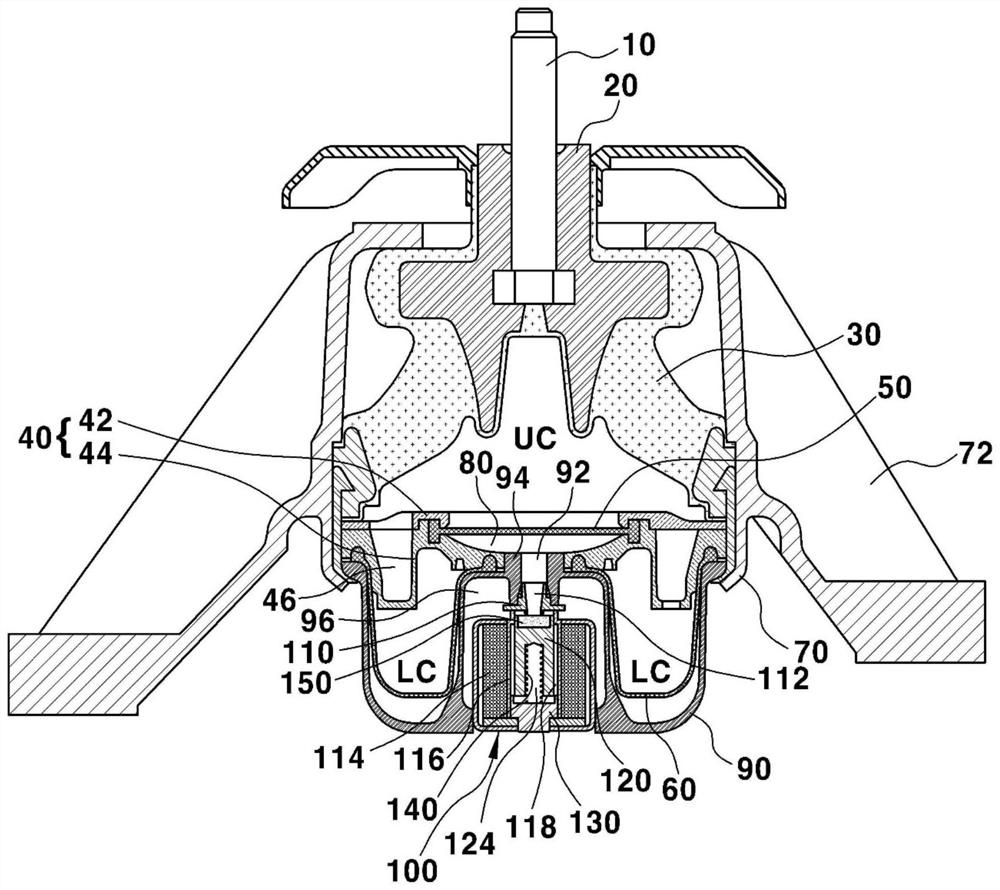

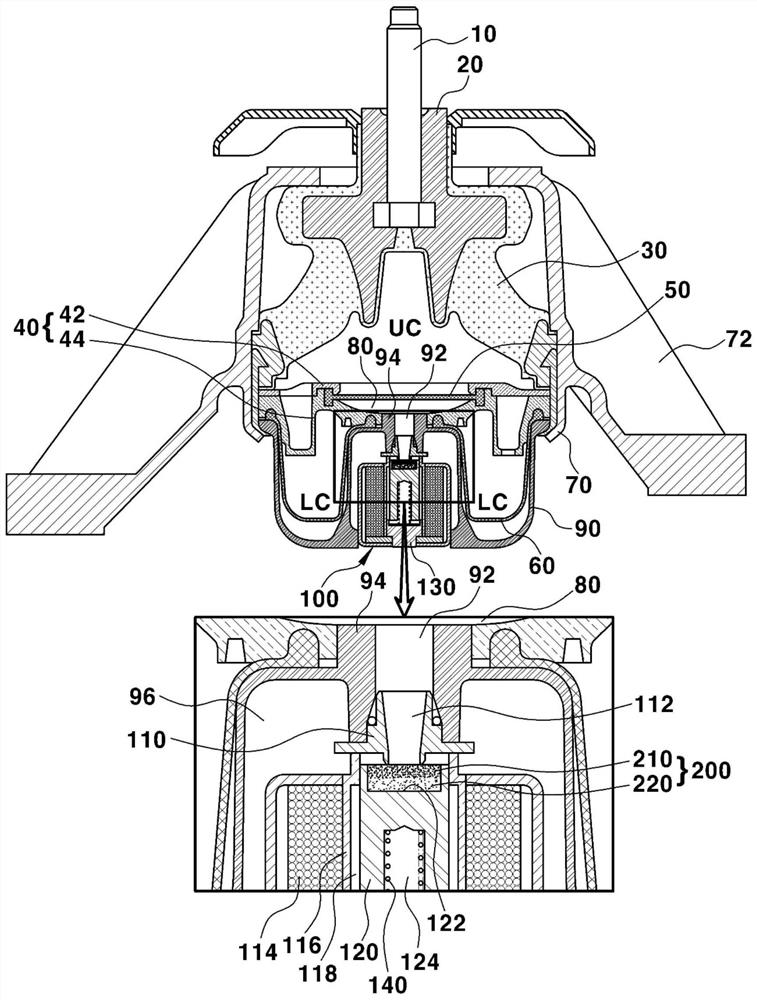

[0078] figure 2 is a cross-sectional view showing the operation sound cancelling device of the semi-active engine mount according to the first embodiment of the present invention.

[0079] According to the first embodiment of the present invention, in the configuration of the solenoid valve 100 , the multi-layer upper stopper 200 formed by stacking the first pad 210 and the second pad 220 on top of each other is inserted into and installed into the upper groove 122 of the plunger 120 . , wherein the first pad 210 is in contact with the bottom surface of the valve housing 110 , and the second pad 220 is attached to the bottom of the first pad 210 and is the same size as the first pad 210 .

[0080] To this end, the first pad 210 and the second pad 220 are adhered to each other by a silicon-based double-sided tape or adhesive having heat resistance, and the bottom of the second pad 220 is attached to the plunger 120 The bottom surfaces of the upper grooves 122 are bonded to ea...

no. 2 example

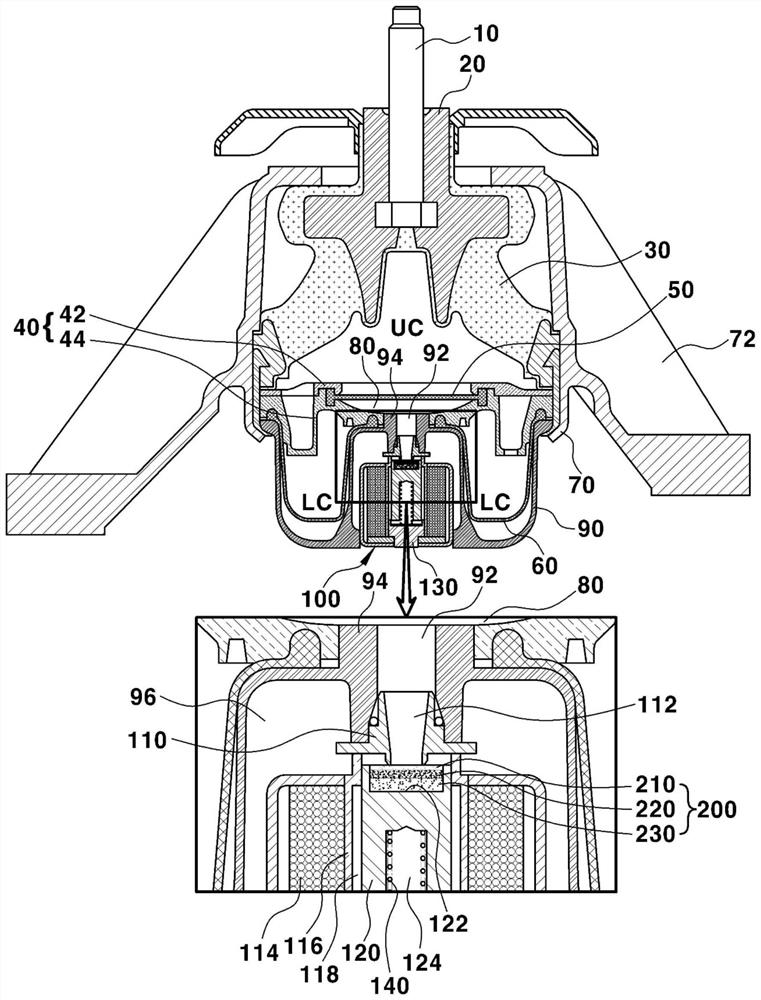

[0093] image 3 is a cross-sectional view showing an operation sound cancelling device of a semi-active engine mount according to a second embodiment of the present invention.

[0094] According to the second embodiment of the present invention, in the configuration of the solenoid valve 100 , the multi-layered upper stopper 200 composed of the first pad 210 , the second pad 220 and the third pad 230 is inserted and mounted to the plunger 120 in the upper groove 122, wherein the first pad 210 is in contact with the valve housing 110, the second pad 220 is attached to the bottom of the first pad 210 and is the same size as the first pad 210, And the third pad 230 is attached to the bottom of the second pad 220 and is the same size as the second pad 220 .

[0095] To this end, the first pad 210 , the second pad 220 and the third pad 230 are adhered to each other by a silicon-based double-sided tape or adhesive having heat resistance, and the third pad 230 is The bottom of the ...

no. 3 example

[0107] Figure 4 is a sectional view showing an operation sound cancelling device of a semi-active engine mount according to a third embodiment of the present invention.

[0108] The third embodiment of the present invention is characterized in that the upper and lower stacking positions of the first pad 210 and the second pad 220 constituting the upper stopper 200 according to the first embodiment are changed.

[0109] That is, in the upper stopper 200 according to the third embodiment of the present invention, the first pad 210 made of hard rubber having a hardness of a predetermined value or more is located below, and the first pad 210 made of soft rubber having a hardness of less than a predetermined value is located below Or a second pad 220 made of sponge foam (eg, porous silicone foam) is stacked on top.

[0110] Therefore, the second pad 220 made of soft rubber or sponge foam having a hardness less than a predetermined value is brought into contact with the valve hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com