End sealing well hoisting hole structure and method for recovering upper traffic of subway station in advance

A technology for subway stations and hoisting holes, which is applied to underwater structures, infrastructure engineering, passing components, etc. It can solve the problems of station roof leakage and high construction costs, achieve good sealing performance, enhance waterproof performance, and prevent pipelines from moving bit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The present invention will be more clearly and completely described below by means of a preferred embodiment in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the described embodiments.

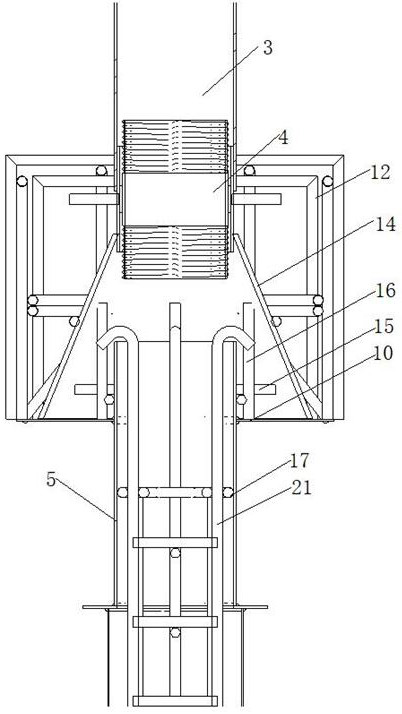

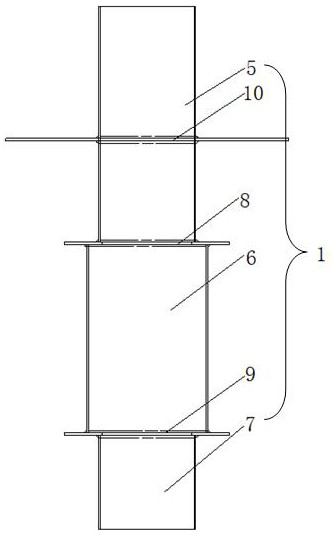

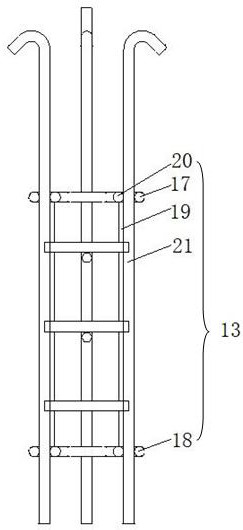

[0078] like figure 1 and figure 2 Shown is a lifting hole structure of a capping head well disclosed in the present invention for restoring the upper part of a subway station to traffic in advance, including a first embedded casing 1 for pre-embedding in the hoisting hole of the station roof and a The second embedded casing 2 of the middle plate of the station is connected to the upper end of the first embedded casing 1 with a connecting joint 4 for connecting the concrete conveying pipes 3 above and below the roof; the first embedded casing 1 includes a top-to-bottom The first pipe section 5, the second pipe section 6 and the third pipe section 7 are arranged concentrically. The diameter of the second pipe section 6 is larger tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com