Composite separation membrane as well as preparation method and application thereof

A separation membrane and polymer technology, applied in the field of preparation of polymer separation membranes, can solve the problems of weak hydrophilicity and achieve the effects of strong hydrophilicity, high utilization rate of raw materials, and short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

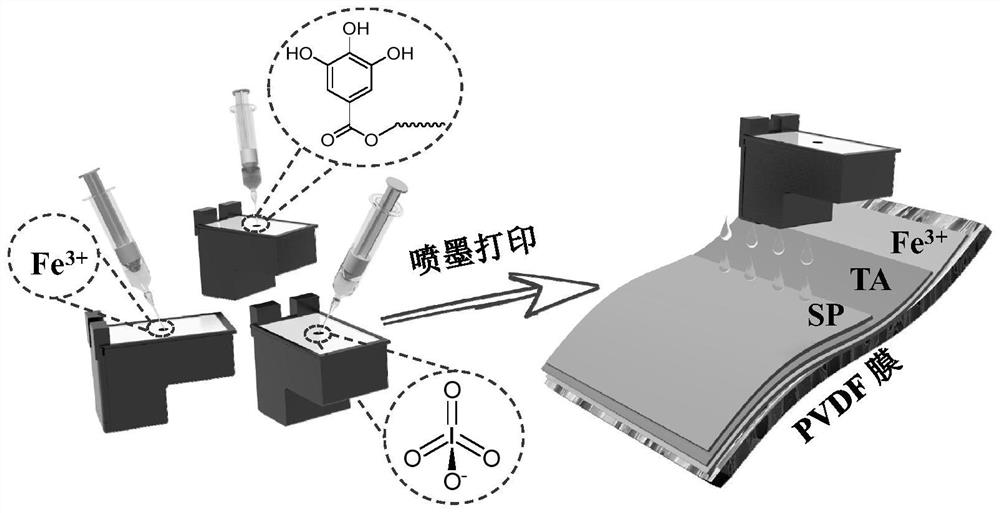

[0037] Example 1: Preparation of hydrophilic Fe-TA-SP composite separation membrane

[0038] (1) Treatment of blank film: first soak the polyvinylidene fluoride film with ethanol for 30 minutes to remove the stains on the surface of the film, then ultrasonically clean the film with pure water for 2-3 times, and finally, dry at 60 °C to obtain a blank film ;

[0039] (2) Ink preparation: prepare a 17% n-propanol solution with distilled water cooled after boiling, add a certain amount of tannic acid to form a 23.5mM tannic acid solution to obtain TA ink; prepare a 17% n-propanol solution with distilled water, use The above solutions were prepared with 11.75mM Fe 2 (SO 4 )3 solution and 47mM NaIO 4 solution to obtain Fe ink and SP ink;

[0040] (3) Equipping ink cartridges: inject the three inks prepared in (2) into three commercial HP ink cartridges with syringes, and equip them for testing on an HP desktop 1112 printer;

[0041] (4) Inkjet printing: paste the blank film tr...

Embodiment 2

[0043] Example 2: Preparation of hydrophilic Fe-TA-SP composite separation membrane

[0044] (1) Treatment of blank film: first soak the polyvinylidene fluoride film in ethanol for 30 minutes to remove the stains on the surface of the film, then ultrasonically clean the film with pure water for 2-3 times, and finally, dry at 60 °C to obtain a blank film ;

[0045] (2) Ink preparation: prepare a 17% n-propanol solution with distilled water cooled after boiling, add a certain amount of tannic acid to form a 23.5mM tannic acid solution to obtain TA ink; prepare a 17% n-propanol solution with distilled water, use The above solutions were prepared with 11.75mM Fe 2 (SO 4 ) 3 solution and 47mM NaIO 4 solution to obtain Fe ink and SP ink;

[0046] (3) Equipping ink cartridges: inject the three inks prepared in (2) into three commercial HP ink cartridges with syringes, and equip them for testing on an HP desktop 1112 printer;

[0047] (4) Inkjet printing: paste the blank film tr...

Embodiment 3

[0049] Example 3: Preparation of hydrophilic Fe-TA-SP composite separation membrane

[0050] (1) Treatment of blank film: first soak the polyvinylidene fluoride film in ethanol for 30 minutes to remove the stains on the surface of the film, then ultrasonically clean the film with pure water for 2-3 times, and finally, dry at 60 °C to obtain a blank film ;

[0051] (2) Ink preparation: prepare a 17% n-propanol solution with distilled water cooled after boiling, add a certain amount of tannic acid to form a 23.5mM tannic acid solution to obtain TA ink; prepare a 17% n-propanol solution with distilled water, use The above solutions were prepared with 11.75mM Fe 2 (SO 4 ) 3 solution and 47mM NaIO 4 solution to obtain Fe ink and SP ink;

[0052] (3) Equipping ink cartridges: inject the three inks prepared in (2) into three commercial HP ink cartridges with syringes, and equip them for testing on an HP desktop 1112 printer;

[0053] (4) Inkjet printing: paste the blank film tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com