Carbon fiber component for shoe sole, shoe sole and shoe

A technology of carbon fiber and components, which is applied in the field of shoe sole preparation, can solve the problems of excessive material, material loss, and increased production cost of carbon plates, etc., and achieve the effect of good force bearing effect and reduced manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

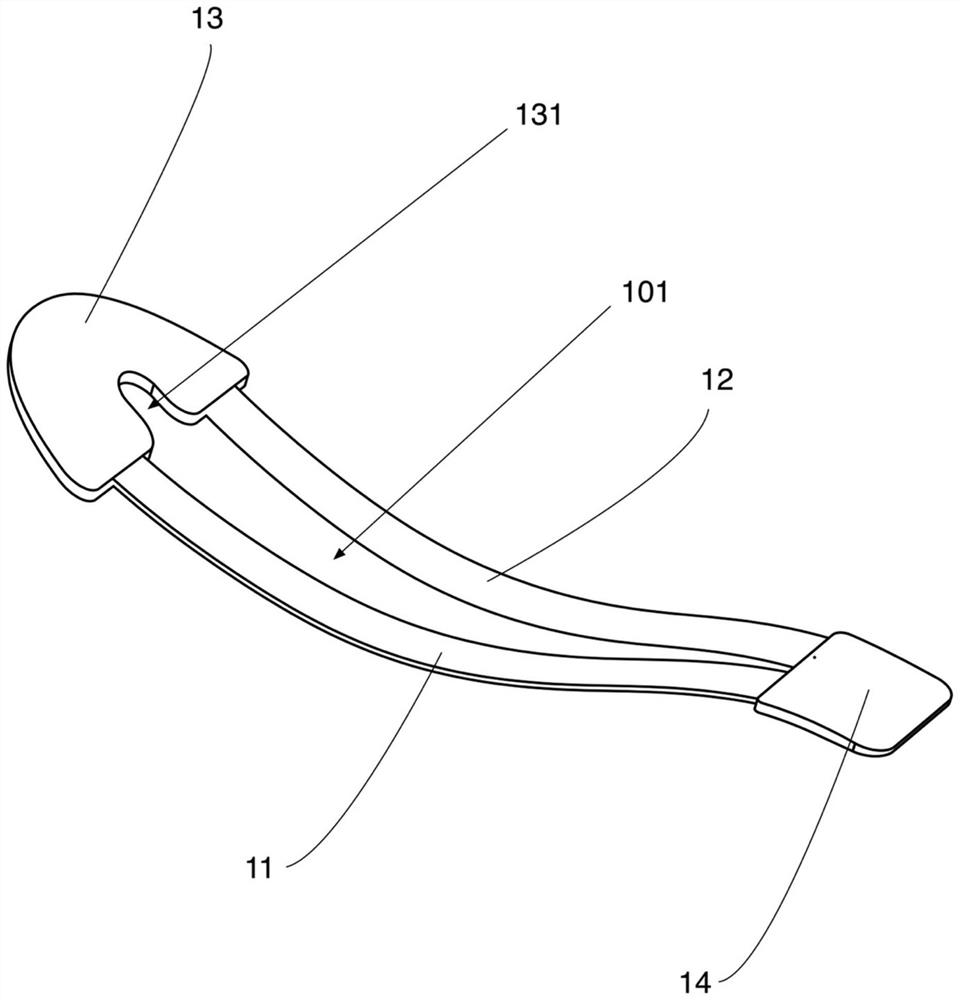

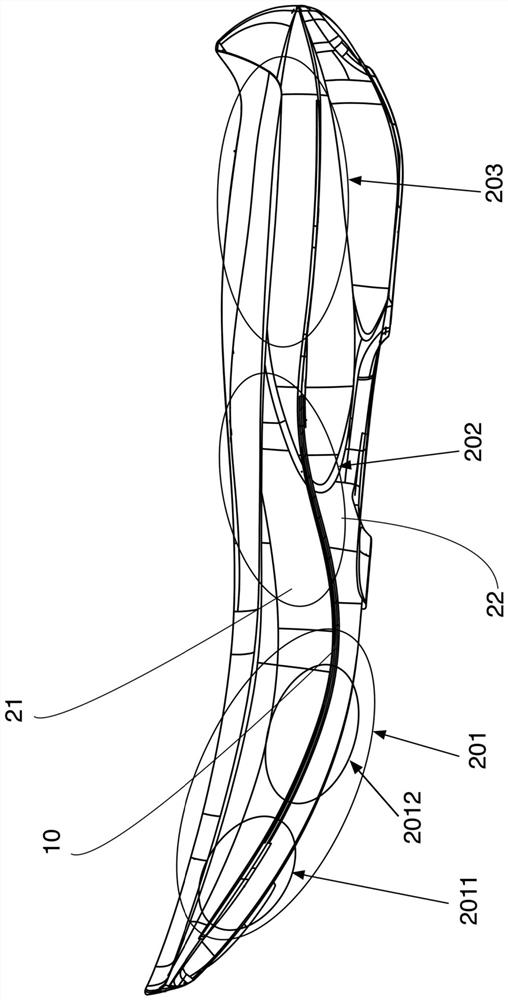

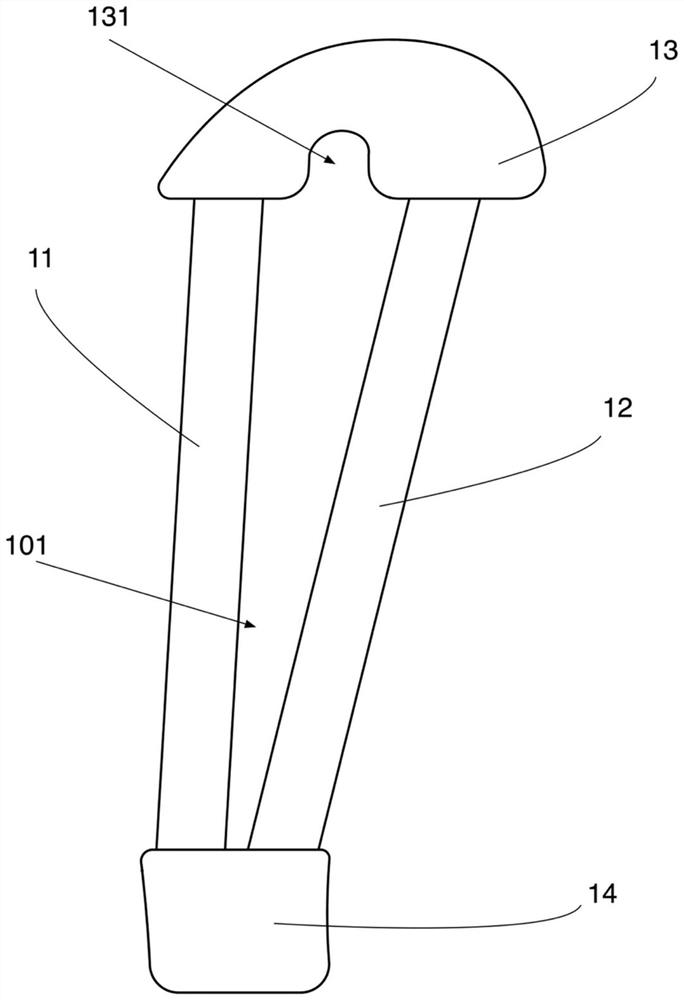

[0043] The first embodiment of the present invention provides a shoe sole, and the structure of the shoe sole refers to figure 2 , which mainly includes an upper midsole 21, a lower midsole 22, a carbon fiber member 10 and a rubber outsole (not shown in the figure).

[0044] The upper midsole 21 is located above the lower midsole 22, the carbon fiber component 10 is located between the upper midsole 21 and the lower midsole 22, and the rubber outsole is compounded under the lower midsole 22. fit etc. The material of the upper midsole 21 and the lower midsole 22 can be EVA or polyurethane, and EVA is used in this embodiment.

[0045] refer to figure 2 , the sole is connected from front to back to form a forefoot portion 201, an arch portion 202 and a rear root portion 203, and the forefoot portion 201 can be further divided into the toe portion 2011 corresponding to the position of the user's toes and the position corresponding to the user's metatarsal bone. Metatarsal at ...

Embodiment 2

[0056] The present invention also provides the second embodiment. The difference between the second embodiment and the first embodiment is that a structure concave up and down in the width direction is provided in the middle position of the first carbon fiber strip 11 and the second carbon fiber strip 12 in the extending direction.

[0057] Specific reference Figure 5 , corresponding to the first carbon fiber strip 11, there is at least a first plane perpendicular to the extension direction of the first carbon fiber strip 11, and the first plane intersects with the first carbon fiber strip at the middle position of its extension direction to form a first cross-section, the first The cross section is bent downward in the width direction of the first carbon fiber 11; similarly, corresponding to the second carbon fiber strip 12, there is at least a second plane perpendicular to the extending direction of the second carbon fiber strip 12, the second plane and the second carbon fib...

Embodiment 3

[0063] The present invention also provides the third embodiment, the third embodiment is a kind of shoe, the shoe includes a kind of sole provided by the above-mentioned first embodiment or the second embodiment, and the shoe upper and other shoe parts are compounded on the sole, And form the above shoes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com