Manufacturing method of preform loose body

A manufacturing method and loose body technology, which can be used in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of easy bending and overhang, large force on the mandrel, affecting the quality of the preform, and achieve the effect of good force effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

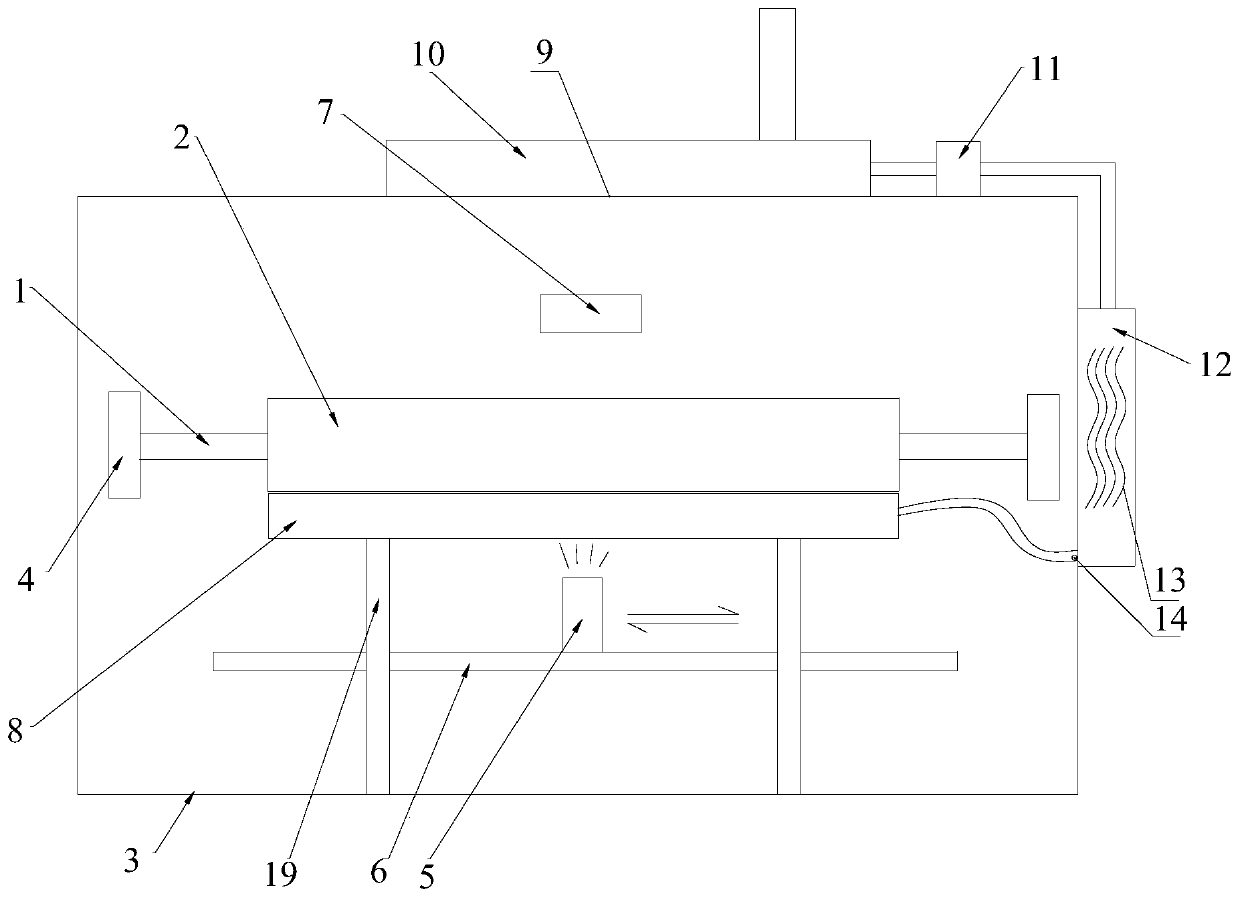

[0042] Below in conjunction with each accompanying drawing, the present invention is described in detail.

[0043] A method for manufacturing a preform loose body, comprising the following steps:

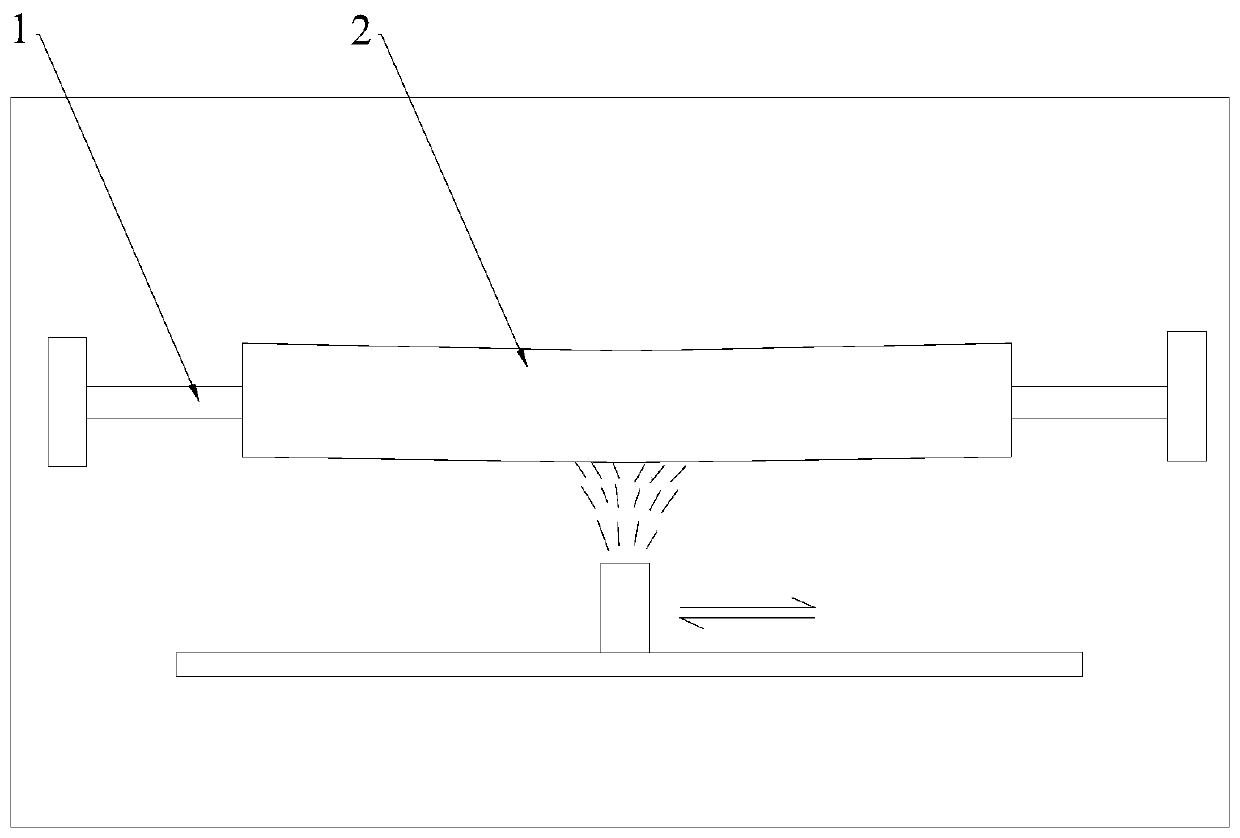

[0044] 1) Clamp the two ends of the mandrel on two chucks respectively, and the chucks drive the mandrel to rotate;

[0045] 2) The blowtorch under the mandrel moves back and forth, so that the particles are deposited on the outer surface of the mandrel to obtain a loose body;

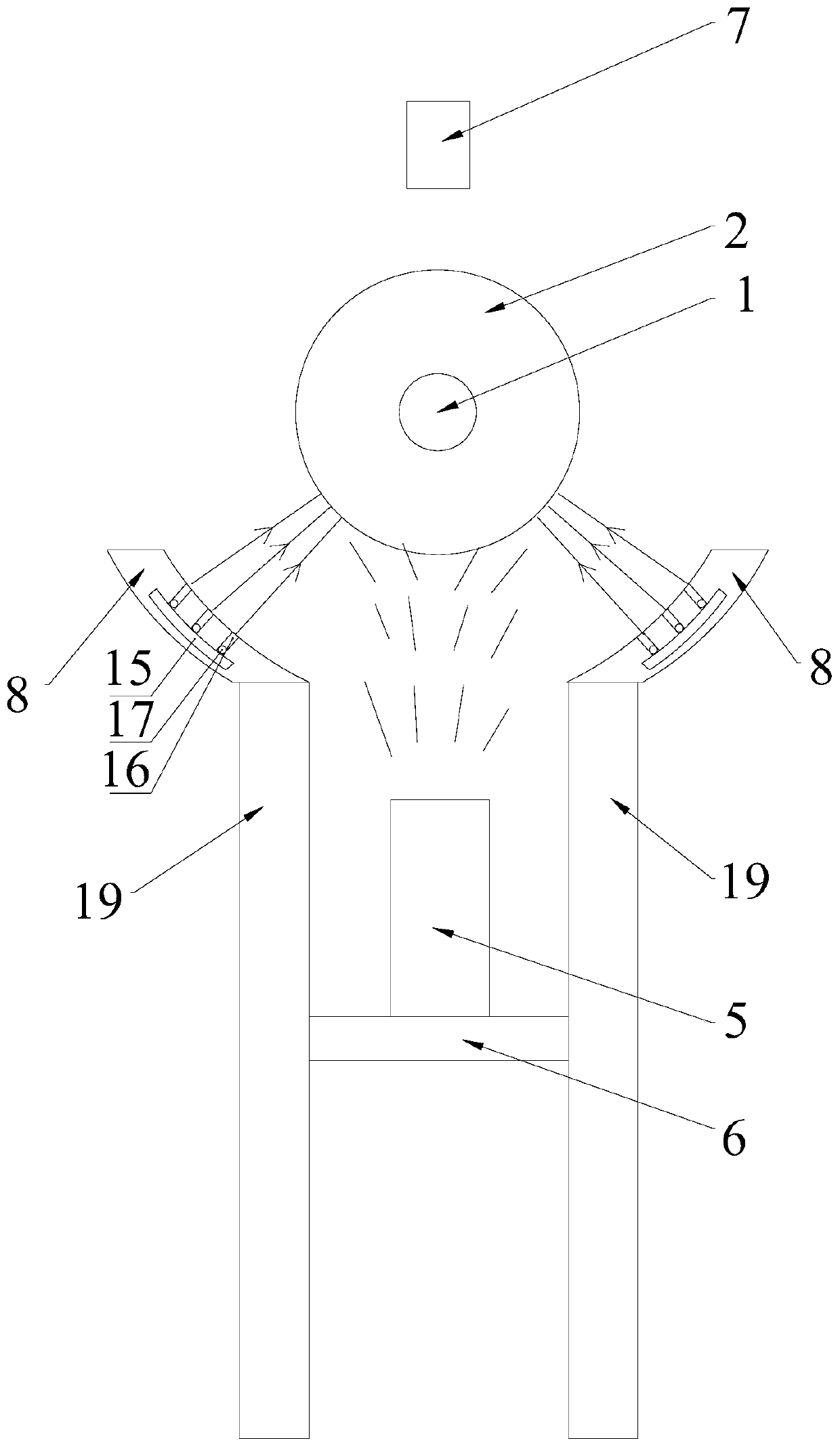

[0046] 3) When the outer diameter of the loose body exceeds the preset critical value, inject gas symmetrically to the loose body on both sides of the lower part of the loose body. The injection direction of the gas is aligned with the mandrel axis, and the closer to the middle of the loose body, the gas The faster the spray speed;

[0047] 4) After the outer diameter of the loose body reaches the set value, the blowtorch stops working;

[0048] 5) After cooling the loose body, stop spraying gas to the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com