Glass product strengthening method

A glass product and product technology, applied in the field of glass product strengthening, can solve the problems of low salt bath life and low production efficiency, achieve high surface CS value, strong crack resistance, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

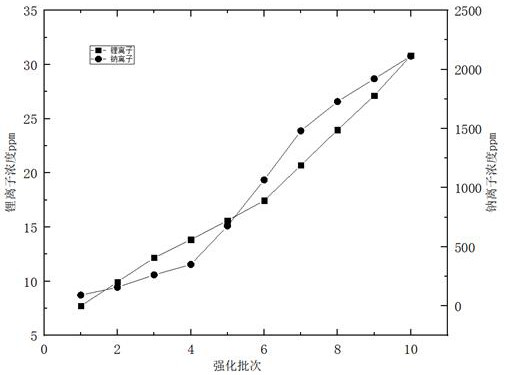

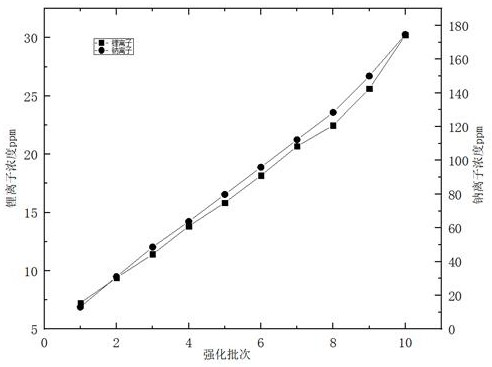

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] One, the relevant special names and relevant measuring methods involved in the present invention are explained as follows

[0023] As used herein, the terms "glass article" are used in their broadest sense to include any object made in whole or in part of glass, including glass ceramics. The glass articles described herein can be formed from alkali aluminosilicate glass compositions that are readily strengthened by ion exchange. Such compositions generally contain SiO 2 、Al 2 o 3 , at least one alkaline earth metal oxide and one or more alkali metal oxides (such as Na 2 O and / or K 2 O) combination.

[0024] Strengthened glass: It is chemically tempered glass after high temperature ion exchange process. Alkali metal ions with a large ionic radius in the high-temperature molten salt replace the alkali metal ions with a small ionic radius in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com