Chemical strengthening method of glass and glass prepared by chemical strengthening method

A glass and chemical technology, applied in the field of chemical strengthening methods and the glass produced, can solve the problems that glass products cannot meet customer reliability requirements, can not meet the requirements of customers, and achieve improved surface CS value, good impact resistance, and improved reliability. Effects of sex test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] A method for chemically strengthening glass, the strengthening method comprising the following steps:

[0102] (a) Preheating for the first time: Preheat the glass to be processed at 300°C for 120 minutes;

[0103] (b), the first ion exchange: ion-exchange the first preheated glass in potassium and sodium mixed molten salt at 415°C for 130 minutes;

[0104] The potassium-sodium mixed molten salt of the first ion exchange is a mixed molten salt of sodium nitrate and potassium nitrate, and the content of sodium nitrate in the mixed molten salt is 50wt%;

[0105] (c) Soaking in water in multiple slots: Pull the glass after the first ion exchange treatment from the unloading car to the air-cooled area within 1 minute, and blow it through a high-power fan to cool it rapidly for 15 minutes; then in the first slot to the second slot Soak in the water of five tanks, wherein:

[0106] Soaking in the first tank is bubbling in pure water at 65°C for 15 minutes;

[0107] Soaking...

Embodiment 2~6 and comparative example 1~3

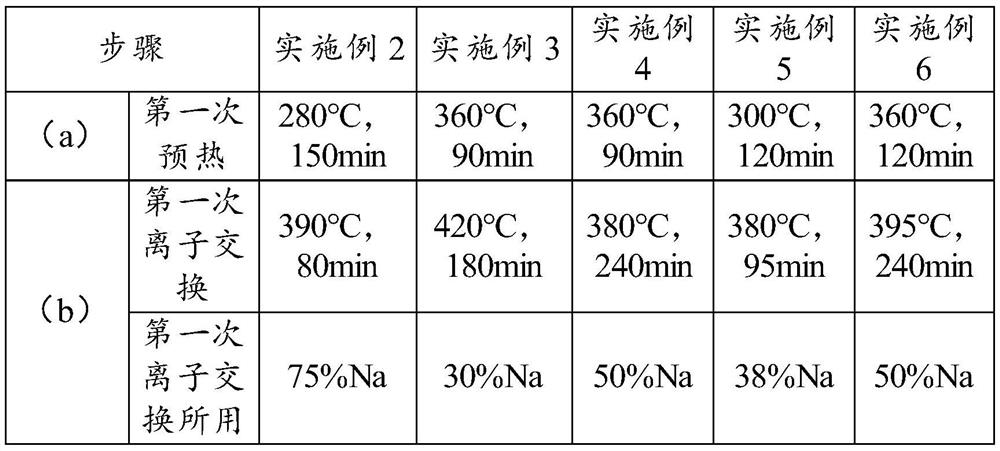

[0117] A kind of chemical strengthening method of glass, described strengthening method comprises the following steps, specifically see table 1, table 2:

[0118] Table 1:

[0119]

[0120]

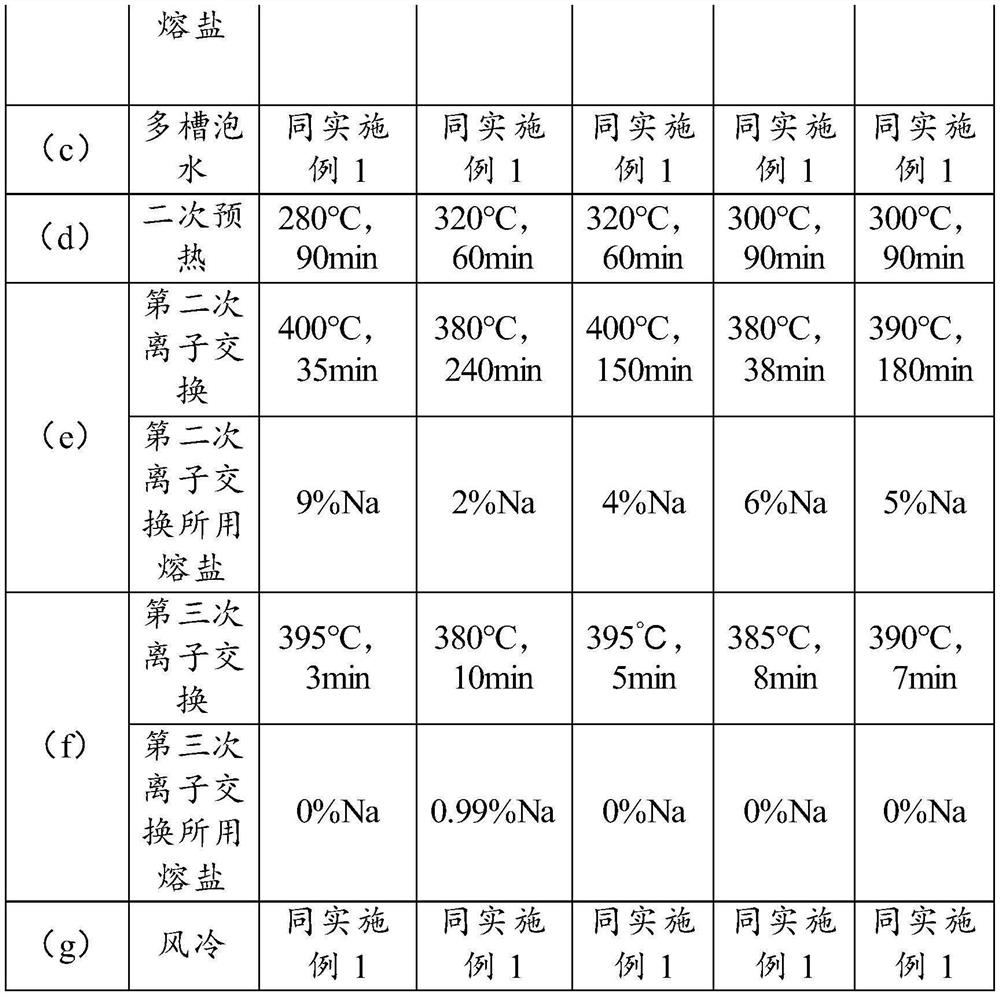

[0121] Table 2:

[0122]

[0123]

experiment example 1

[0144] In order to show that the strengthened glass prepared by the chemical strengthening method of the present application can greatly increase the surface stress CS value of the glass compared with the existing secondary strengthened glass, and at the same time its reliability strength can also be greatly increased by 20-30%. The tempered glass prepared in Examples 1-6 and Comparative Examples 1-6 is now used for stress value and reliability performance testing, and the specific results are shown in the following table:

[0145] table 3:

[0146]

[0147]

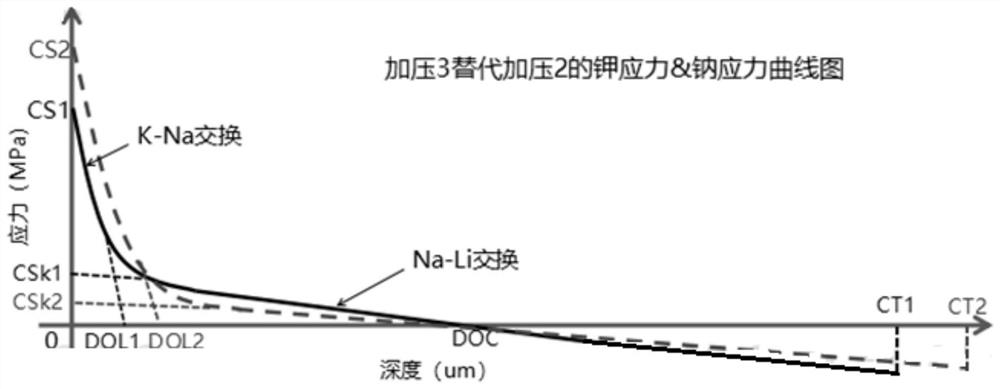

[0148] Note: The above DOL is the depth of the surface stress layer; DOC is the total depth of the ion exchange stress layer; CS is the surface compressive stress; CSK is the corner compressive stress; CT is the central tensile stress; 4PB is the four-point bending test; ROR is the central static pressure test ; The sandpaper is dropped for the whole machine.

[0149] It can be seen from the above experimental exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com