Boswellia butter with natural flavor and preparation method thereof

A natural flavor and frankincense technology, applied in the field of spices, can solve the problems of weak milk fat flavor, low production cost, and insufficient full and strong mastic flavor, and achieve outstanding milk flavor, mutton smell and baking aroma performance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

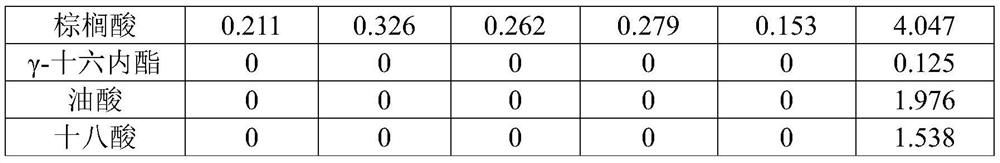

Examples

Embodiment 1

[0015] 200g of anhydrous cream was added to 20g of 0.2mol / L dipotassium hydrogen phosphate buffer, 10g of O.D.O was added, the mixture was placed in a conical flask, and 0.1g of Newlase F3G lipase was added at 45°C under shaking conditions of 190r / min. The enzymatic hydrolysis reaction was carried out for 3 hours. After the enzymatic hydrolysis was completed, the temperature was rapidly heated to 90 °C for 20 minutes. The water was separated from the separatory funnel to obtain 192 g of frankincense with characteristic flavor, with an acid value of 62 (KOH) / (mg / g).

Embodiment 2

[0017] 200g of anhydrous cream was added to 20g of 0.2mol / L dipotassium hydrogen phosphate buffer, 20g of O.D.O was added, the mixture was placed in a conical flask, and 0.4g of RM-IM lipase was added at 45°C, shaking at 190r / min. The enzymatic hydrolysis reaction was carried out for 1 h. After the enzymatic hydrolysis was completed, the temperature was rapidly heated to 90 ° C for 20 min. The water was separated from the separatory funnel to obtain 188 g of frankincense with characteristic flavor, with an acid value of 79 (KOH) / (mg / g).

Embodiment 3

[0019] 200g of anhydrous cream was added to 20g of 0.2mol / L dipotassium hydrogen phosphate buffer, 10g of O.D.O was added, the mixture was placed in a conical flask, and 0.1g of Lipase A12 lipase was added. The enzymatic hydrolysis reaction was carried out for 4 hours. After the enzymatic hydrolysis was completed, the temperature was rapidly heated to 90 °C for 20 minutes. The water was separated from the separatory funnel to obtain 192 g of frankincense with characteristic flavor, with an acid value of 70 (KOH) / (mg / g).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com