High-performance magnesium metal matrix composite material and preparation method thereof

A composite material, magnesium metal technology, applied in the new material and preparation process, high-performance LPSO structure reinforced magnesium metal matrix composite material and its preparation field, to achieve the effect of flexible addition, expansion of effective existence and application range, and improvement of performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

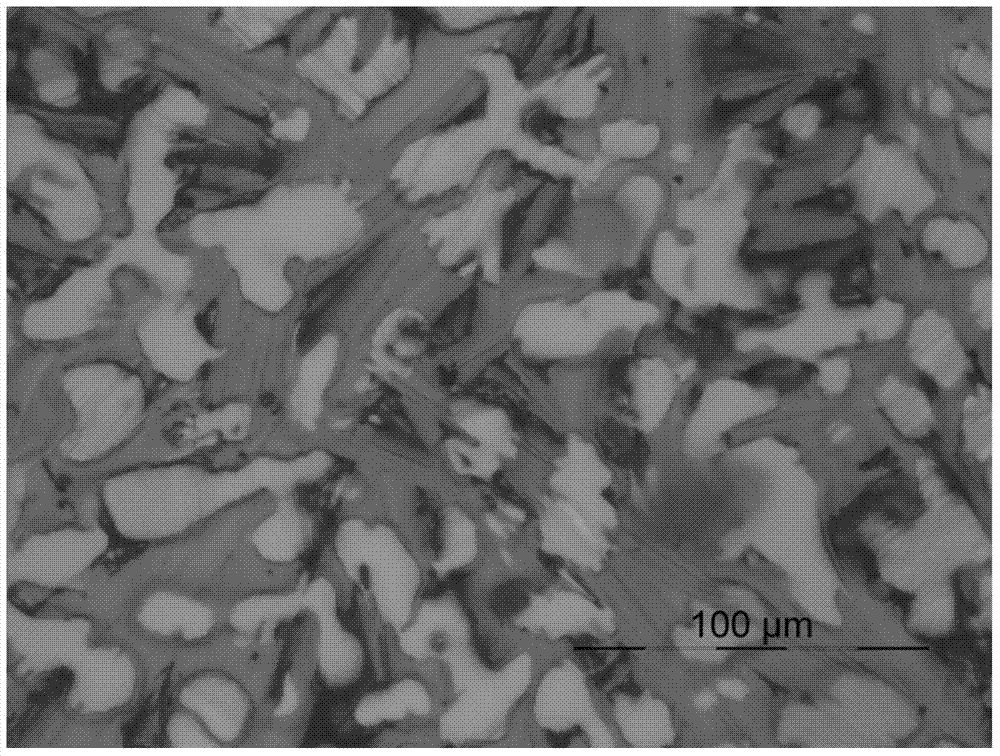

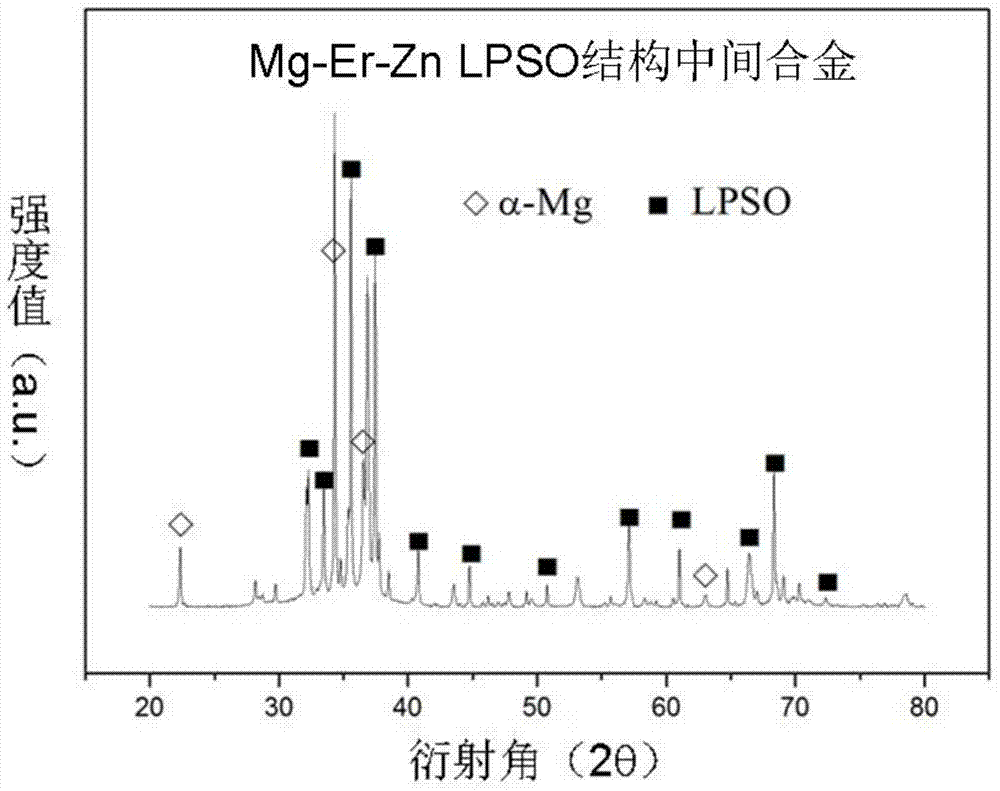

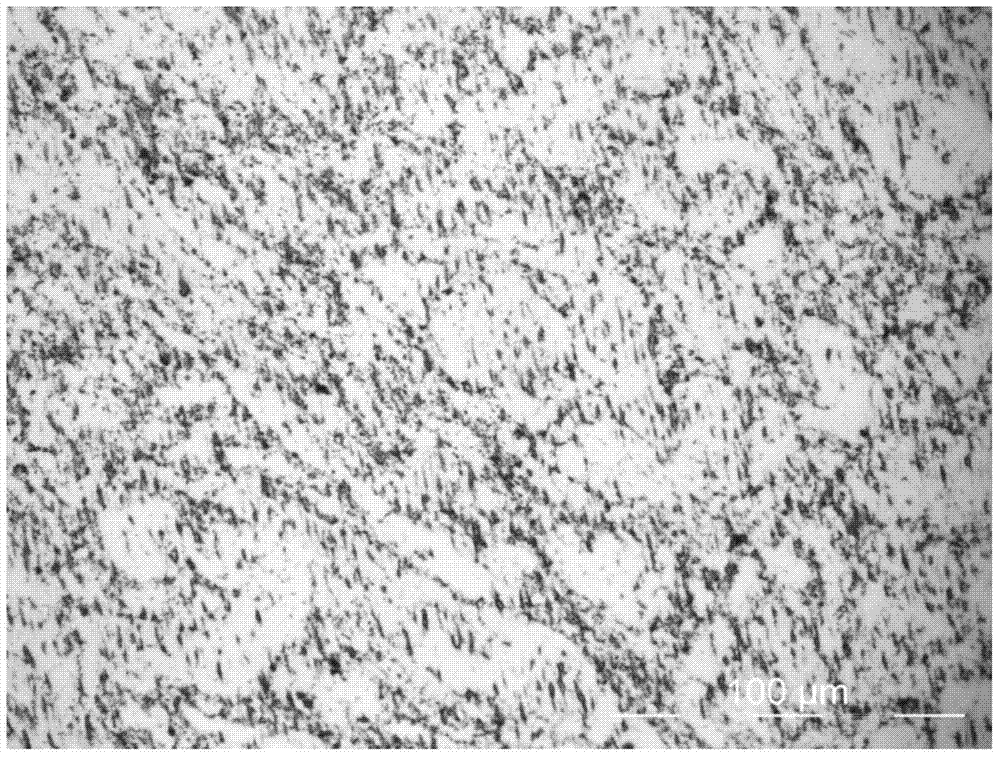

Embodiment 1

[0026] Taking industrial pure magnesium as the base material as an example, firstly, industrial pure magnesium and LPSO structure master alloy (65%) are ground and processed to obtain metal particles and mixed. The mass ratios of the two are respectively 90% and 10%. After uniformity, place it in a grinder and grind for 25 minutes. Secondly, the mixed and ground powder is placed in a multi-cycle plastic deformation device for compression processing, the number of times of pressing is 5 times, and the load force is 20t, and finally an extrusion blank is obtained. Thirdly, the extruded blank was annealed in a furnace at a temperature of 400° C., kept for 15 minutes, protected by argon, and cooled naturally in air. Fourth, the extrusion blank is subjected to extrusion processing. First, it is kept in a holding furnace at a temperature of 250°C for 1.5h, and then extruded immediately. The extrusion ratio is 16. Finally, the tensile and yield strengths of the obtained alloy are re...

Embodiment 2

[0028] Taking industrial pure magnesium as the base material as an example, firstly, industrial pure magnesium and LPSO structure master alloy (65%) are ground and processed to obtain metal particles and mixed. The mass ratios of the two are respectively 75% and 25%. After uniformity, place it in a grinder and grind for 15 minutes. Secondly, the mixed and ground powder is placed in a multi-cycle plastic deformation device for compression processing, the number of times of pressing is 5 times, and the load force is 30t, and finally an extrusion blank is obtained. Thirdly, the extruded blank was annealed in a furnace at a temperature of 400° C., kept for 25 minutes, protected by argon, and cooled naturally in air. Fourth, carry out extrusion processing on the extruded blank, first heat it in a holding furnace at a temperature of 300°C for 0.5h, and then extrude immediately, with an extrusion ratio of 16. Finally, the tensile and yield strengths of the obtained alloy are respect...

Embodiment 3

[0030] Taking AZ31 as the base material as an example, first, AZ31 and LPSO structure master alloy (65%) are ground and processed to obtain metal particles and mixed. The mass ratios of the two are 90% and 10% respectively. In a grinder, grind for 30 min. Secondly, the mixed and ground powder is placed in a multi-cycle plastic deformation device for compression processing, the number of times of pressing is 5 times, and the load force is 40t, and finally an extrusion blank is obtained. Thirdly, the extruded blank was annealed in a furnace at a temperature of 400° C., kept for 30 minutes, protected by argon, and cooled naturally in air. Fourth, the extrusion blank is subjected to extrusion processing. First, it is kept in a holding furnace at a temperature of 300°C for 1 hour, and then extruded immediately. The extrusion ratio is 16. Finally, the tensile and yield strengths of the obtained alloy are 270MPa and 185MPa respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com