Combined vertical hanging and dry hanging system

A combination type, vertical hanging technology, applied in the direction of covering/lining, construction, building structure, etc., can solve the problems of difficult adjustment of flatness, waste of materials, non-environmental protection, etc., to achieve convenient and fast installation and disassembly Environmentally friendly and use reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

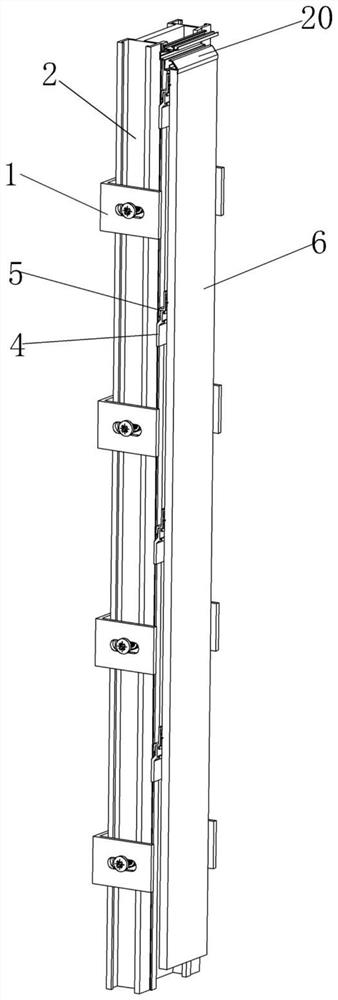

[0037] Embodiment 1: A combined vertical hanging dry hanging system provided in this embodiment is mainly composed of a U-shaped base 1, a vertical keel 2, a horizontal keel 4 and a hanging piece 5. The U-shaped base 1 is exploded Screws are fixed on the wall 24, the U-shaped base 1 is installed with a vertical keel 2, a connection base 3 is installed in the vertical keel 2, and a horizontal keel 4 is installed on one side of the connection base 3, so The connecting base 3 and the horizontal keel 4 are fixedly and clamped on the vertical keel 2 by screws, and a hanging piece 5 is installed on the horizontal keel 4, and a rock plate 6 is installed on the hanging piece 5, and the rock plate 6 passes through. The hanging piece 5 is installed on the horizontal keel 4 .

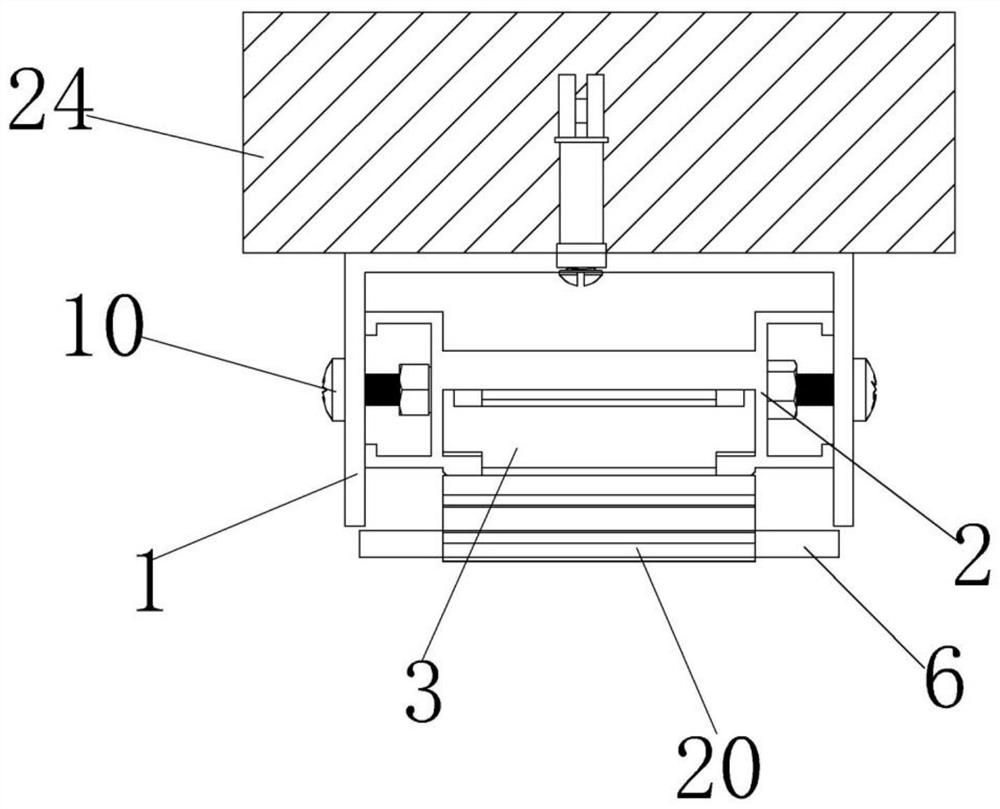

[0038] The U-shaped base 1 includes a mounting portion 7 and a bending portion 8 disposed at both ends of the mounting portion 7 . Both the mounting portion 7 and the bending portion 8 are provided with mounting h...

Embodiment 2

[0040] Embodiment 2: This embodiment further makes the following installation scheme as an improvement on the basis of the above-mentioned Embodiment 1. First, the U-shaped base 1 is installed on both sides of the vertical keel 2 by adjusting screws 10, and then the U-shaped base 1 is installed on the vertical keel 2. Install the explosion screw on the top, and the explosion screw passes through the vertical keel 2 and the U-shaped base 1 in turn, so as to install the U-shaped base 1 and the vertical keel 1 on the wall 24, and then install the connection base 3 in the vertical keel 2 in turn. , the horizontal keel 4 and the hanging piece 5, this installation method is different from the first embodiment, the U-shaped base 1 and the vertical keel 2 are first installed on each other, and then installed on the wall 24 through the explosion screw, and this installation is adopted. In this way, the quick installation of the U-shaped base 1 and the vertical keel 2 is realized, and th...

Embodiment 3

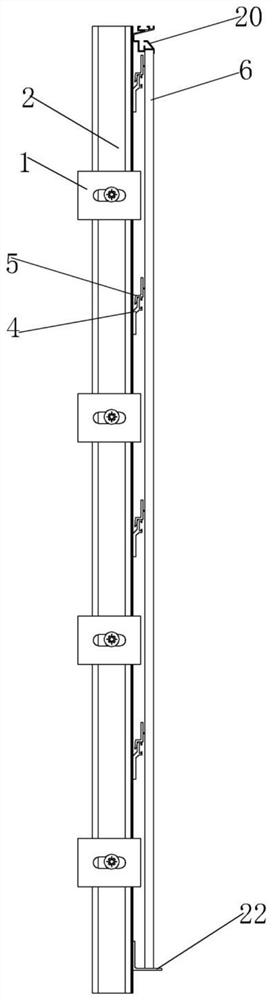

[0041] Embodiment 3: One end of the vertical keel 2 is installed with a trim strip 20, the edge trim 20 is mounted on the vertical keel 2 by screws, and is installed at the opening of the snap groove 11, and the edge trim 20 is provided with Matching groove 21, the rock plate 6 is installed in the matching groove 21, and the hanging piece 5 includes a hanging end 18 and a connecting end 19. The hanging end 18 is arranged below the connecting end 19. During installation, the hanging piece 5 is on the The hanging end 18 of the hanging piece is installed on the hanging end 16 of the horizontal keel 4, and the connecting end 19 of the hanging piece 5 is installed with the rock plate 6.

[0042] The rock plate 6 is installed on the hanging piece 5 in advance by means of plugging and other methods to form a whole, and then the hanging piece 5 is installed on the horizontal keel 4. At this time, one end of the hanging piece 5 is inserted into the matching groove 21 of the edge strip 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com