Color printing paper adhesion system and process for annular packaging piece

A technology for packaging parts and color printing paper, applied in the field of product packaging, can solve the problems of large amount of preparation work for pasting work, lack of information on color printing paper, low work efficiency, etc., and achieve efficient adhesion process and simple adhesion action. , the effect of improving the adhesion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

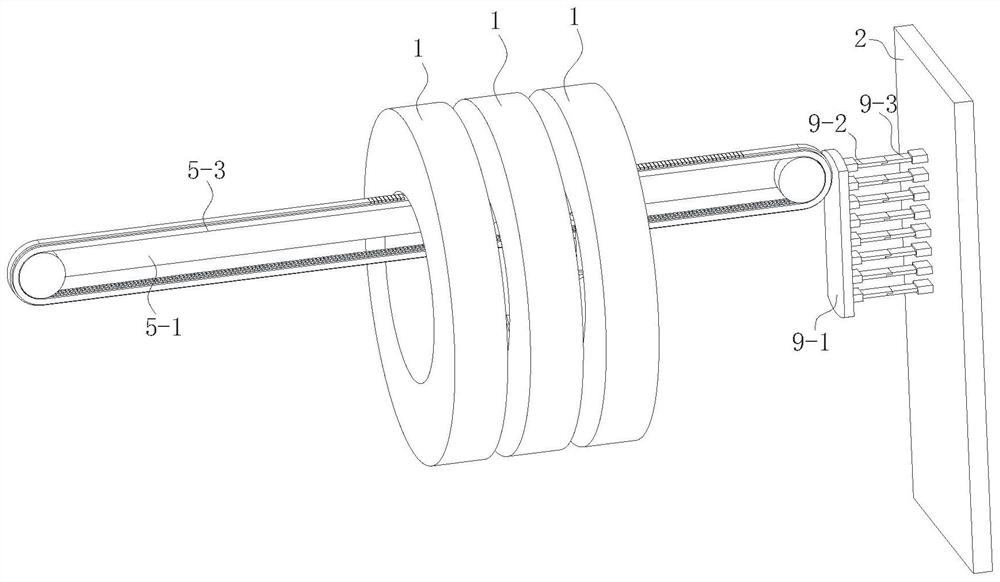

[0033] see Figure 1-9 , the present invention provides a technical solution: a color printing paper adhesion system for a ring-shaped package, including a ring-shaped package 1, the inner wall of the ring-shaped package 1 is suspended on a transmission mechanism, and the transmission mechanism is fixedly connected with an adhesion mechanism, so The adhering mechanism can paste color printing paper at the fixed lateral position of the inner wall of the ring-shaped package 1 during the transportation of the ring-shaped package 1, and the right side of the transmission mechanism is fixedly connected with a return mechanism, and the return mechanism is fixedly connected with a Support mechanism 2.

[0034] By suspending the ring-shaped package 1 on the conveying mechanism, in the process of being directly transported by the conveying mechanism to the ejecting mechanism, the ring-shaped package 1 passes through the adhering mechanism, and the adhering mechanism can be transported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com