Swinging progressive scraper unloading device and dumper

A technology of unloading device and dump truck, which is applied to the arrangement of loading and unloading vehicles, motor vehicles, vehicles with push plates, etc., and can solve the problem of vehicles exceeding the load limit of the hopper of the paver, affecting the service life of the paver, and affecting the dump truck Problems such as bucket lifting and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

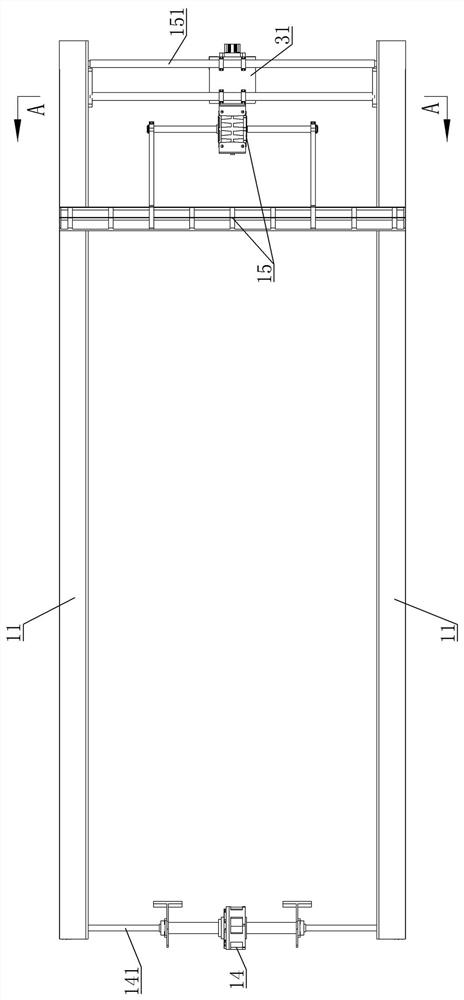

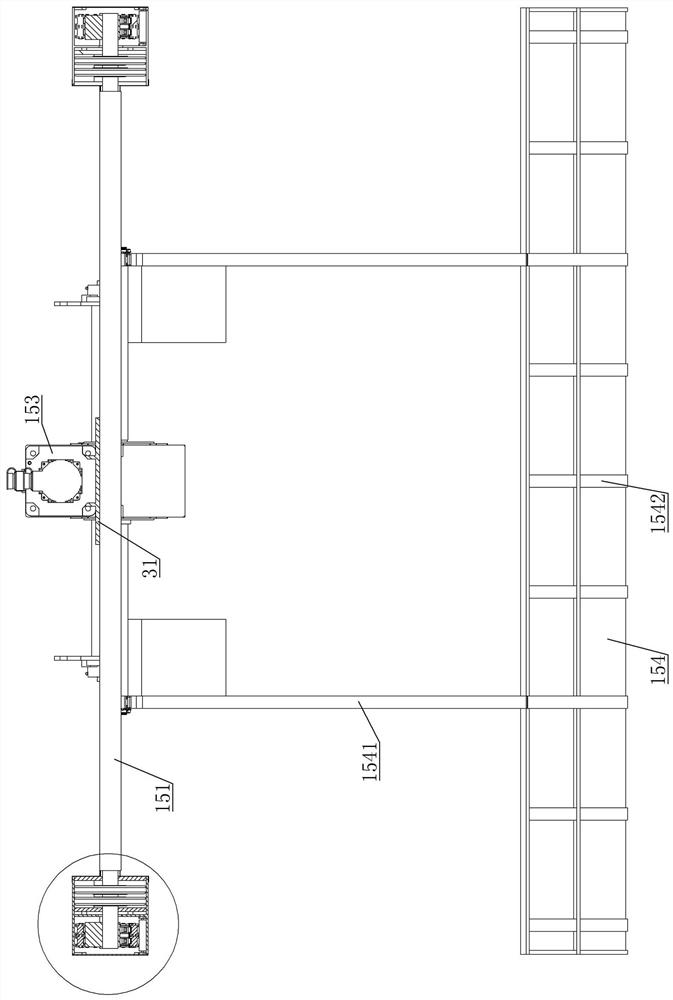

[0031] Embodiment 1, see the appendix of the specification figure 1 - 8. A oscillating progressive scraper unloading device, which can be used for unloading granular materials or ready-mixed materials, the device includes two symmetrically arranged support profiles, and an accommodating cavity inside the support profiles A driving sprocket is installed at the front end, and a driven sprocket is installed at the rear end of the accommodating cavity. A chain is sleeved between the driving sprocket and the driven sprocket. Maintenance, the inner side of the accommodating cavity is provided with a chute, and the partition between the chute and the accommodating cavity is provided with a long sliding hole along the length direction, the long sliding hole extends to both ends of the supporting profiles, between the front ends of the two supporting profiles There is a double-shaft hydraulic motor. The two shafts of the double-shaft hydraulic motor are coaxially and fixedly connected...

Embodiment 2

[0039] Embodiment 2, referring to Figures 1-13 in the specification, a dump truck includes a box transporter and the swinging progressive scraper unloading device described in the first embodiment. The body of the box transporter is set as a square body. , The two supporting profiles of the swing progressive scraper unloading device are symmetrically and fixedly connected to the upper end faces of the two side plates of the square body. The length of the supporting profiles is the same as the length of the square body. The two-axis hydraulic motor is fixedly connected to the body through the bracket. The width of the scraper matches the width of the square body, and the lower end of the scraper can contact the bottom surface of the square body, and the rear end plate of the square body is provided with a tailgate.

[0040] A beam is arranged above the rear end of the square body, the upper end of the tailgate is hinged with the beam, and an electric push rod is hinged in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com