Self-propelled rock cutting machine and mechanical cutting mining method

A self-propelled, cutting machine technology, applied in the field of mechanical cutting mining, self-propelled rock cutting machine, can solve the problems of safety accidents, the stability of the stope roof and the surrounding rock of the upper wall, and damage, and achieve the goal of safety guarantee Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

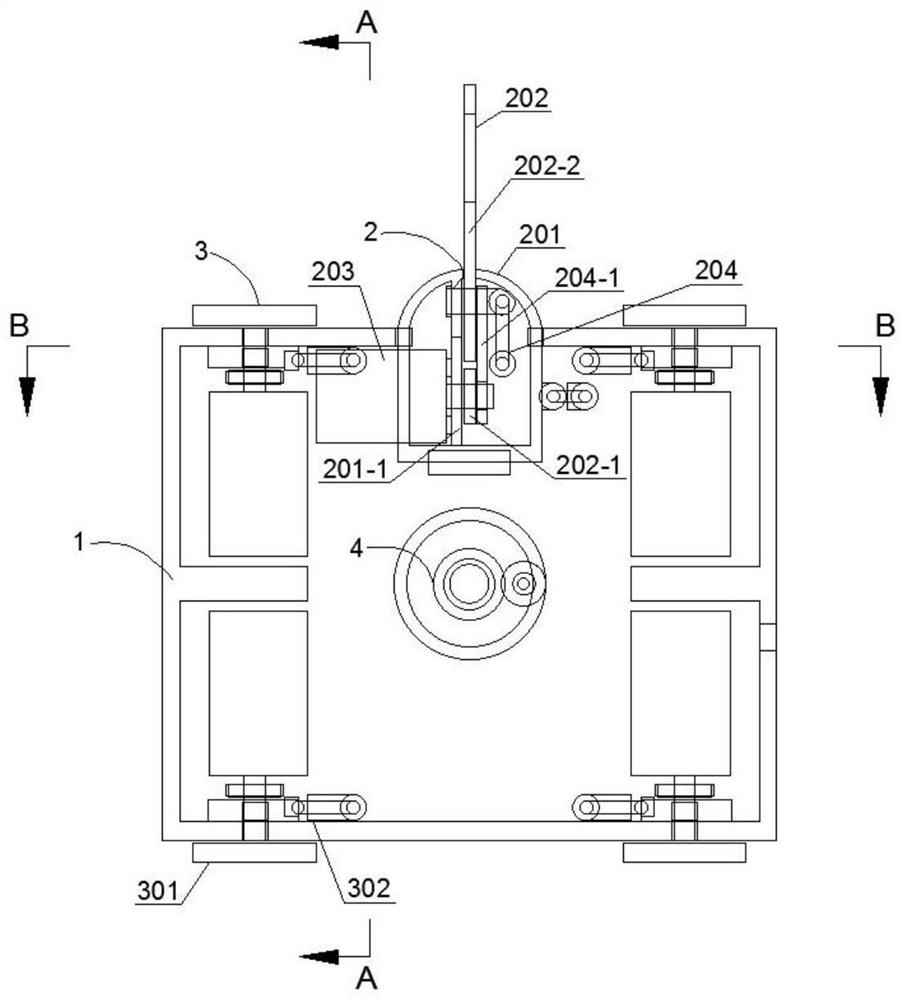

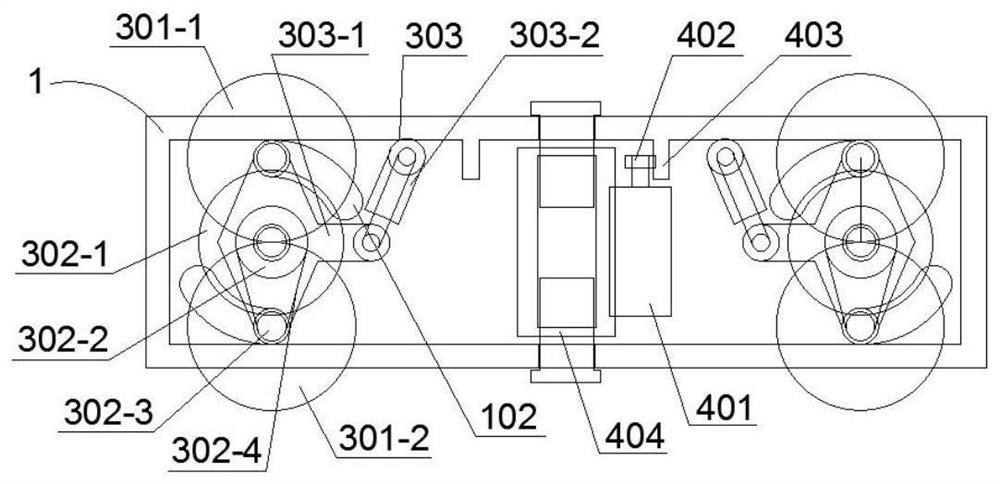

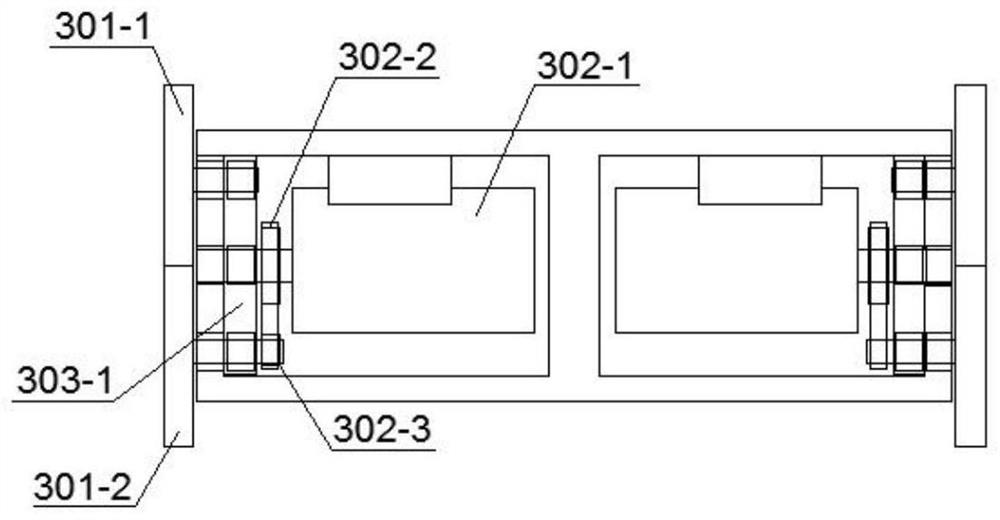

[0094] In order to solve the problem that the existing rock cutting machine cannot penetrate deep into the rock, the embodiment of the present invention provides a self-propelled rock cutting machine, such as Figure 1-4 As shown, it includes a body 1, and the body 1 is provided with a cutting mechanism 2, a traveling mechanism 3, and a rotating mechanism 4.

[0095] In this embodiment, the moving mechanism 3 drives the body 1 to move. During the movement of the body 1, the cutting mechanism 2 can cut the rock, and the body 1 can also walk in the slot cut by the cutting mechanism 2, so as to cut deep into the rock. The slewing mechanism 4 can drive the body 1 to rotate as a whole, so as to complete the turning and rotating cutting operations of the body 1 .

[0096] In this embodiment, the body 1 is a rectangular frame structure, that is, the interior of the body 1 is a hollow structure, which is used to install and support the cutting mechanism 2, the traveling mechanism 3 an...

Embodiment 2

[0148] Self-propelled rock cutting machine, different from Embodiment 1, the structure of the chainsaw 202 of this embodiment is as follows Figure 16 As shown, the shape of the through groove 202-2-1 opened at the front end of the chain saw plate 202-2 in this embodiment is circular, that is, the chain saw 202 in this embodiment is a circular hollow chain saw.

Embodiment 3

[0150] Self-propelled rock cutting machine, different from Embodiment 1, the chain saw 202 of this embodiment is a bearing-type chain saw, such as Figure 17-18 As shown, it specifically includes a chainsaw sprocket 202-1, a chainsaw plate 202-2, a chainsaw bearing 202-4, and a drive chain 202 wound around the chainsaw sprocket 202-1 and the chainsaw bearing 202-4 -5.

[0151] like Figure 18 As shown, the chain saw bearing 202-4 of this embodiment consists of a bearing outer circle 202-4-1, a bearing inner circle 202-4-2, and a bearing outer circle 202-4-1 and a bearing inner circle 202- The bearing balls 202-4-3 between 4-2 are composed; the longitudinal section of the bearing outer circle 202-4-1 in this embodiment is H-shaped, and the outer wall of the bearing outer circle 202-4-1 is sprayed with diamond abrasives , the bearing inner circle 202-4-2 is accommodated in the inner cavity of the bearing outer circle 202-4-1, so as to form protection for the bearing inner circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com