Processing method of profile steel for steel structure manufacturing

A processing method and technology of steel structure, applied in the field of section steel processing, can solve the problems of difficult to ensure uniform product performance, inconvenient drilling processing of section steel, affecting the use of drilling devices, etc., achieving good fixing effect, improving forming speed, and improving strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

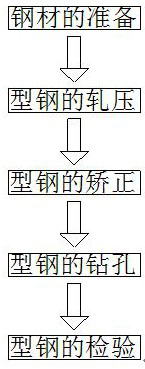

[0049] like Figure 1-6 As shown, the present invention provides a processing method of a profiled steel for the manufacture of a steel structure, and the processing method of the profiled steel for the manufacture of a steel structure comprises the following steps:

[0050] Step 1: Preparation of steel;

[0051] Step 2: Rolling of section steel;

[0052] Step 3: Correction of section steel;

[0053] Step 4: Drilling of section steel;

[0054] Step 5: Inspection of section steel.

[0055] Step 1 also includes the following steps:

[0056] A1: Prepare the steel required to make the section steel, and the steel is Q235 carbon structural steel;

[0057] A2: Prepare the mechanical equipment for processing section steel, and debug these equipment.

[0058] Step 2 also includes the following steps:

[0059] B1: Place the steel in the universal rolling mill, start the universal rolling mill, the web of the section steel is rolled between the upper and lower horizontal rolls, and...

Embodiment 2

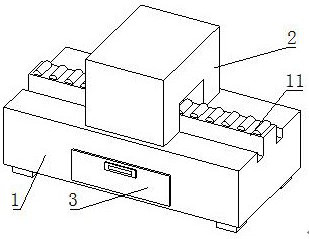

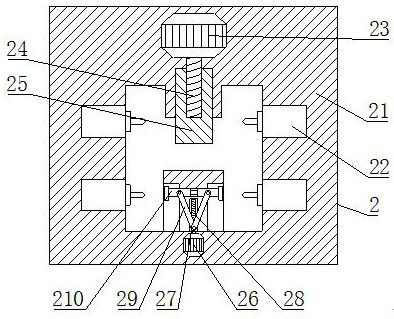

[0073] like Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the drilling equipment includes a drilling table 1 and a drilling device 2, and the drilling device 2 is fixedly connected to the drilling table 1. On the top, the top of the drilling table 1 is fixedly connected with the transfer table 11 , the side of the drilling table 1 is provided with a chip cleaning mechanism 3 , the drilling device 2 includes a fixed frame 21 , and the fixed frame 21 is fixedly connected to the drilling table 1 . The top of the fixed frame 21 is fixedly connected with a drilling machine 22 on both sides of the interior, the inner top of the fixed frame 21 is fixedly connected with a first motor 23, and the output shaft of the first motor 23 is fixedly connected with a first screw 24, the first screw The side surface of 24 is screwed with a threaded push block 25, the inner bottom end of the fixing frame 21 is fixedly connecte...

Embodiment 3

[0076] like Figure 1-6 As shown, on the basis of Embodiment 2, the present invention provides a technical solution: preferably, the threaded push block 25 includes a moving block 251, the moving block 251 is threadedly connected to the side of the first screw 24, and the bottom end of the moving block 251 A top block 252 is movably connected internally, a top tightening spring 253 is provided on the top of the top block 252, a pull rod 254 is movably connected to the side of the top block 252, and one end of the pull rod 254 is movably connected with a top rod 255, and one end of the top rod 255 is fixedly connected with a Top plate 256.

[0077] In this embodiment, when the threaded push block 25 moves, the top block 252 will be squeezed, and the top block 252 will be pressed against the push-up spring 253, so that the pull rod 254 can pull the top rod 255 to move. , so that the top rod 255 can push out the top plate 256 , thereby facilitating the fixing of the profiled ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com