Cookware and manufacturing method thereof

A manufacturing method and pot technology, applied in the field of kitchen utensils, can solve the problems of high density, affecting end grip, low density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

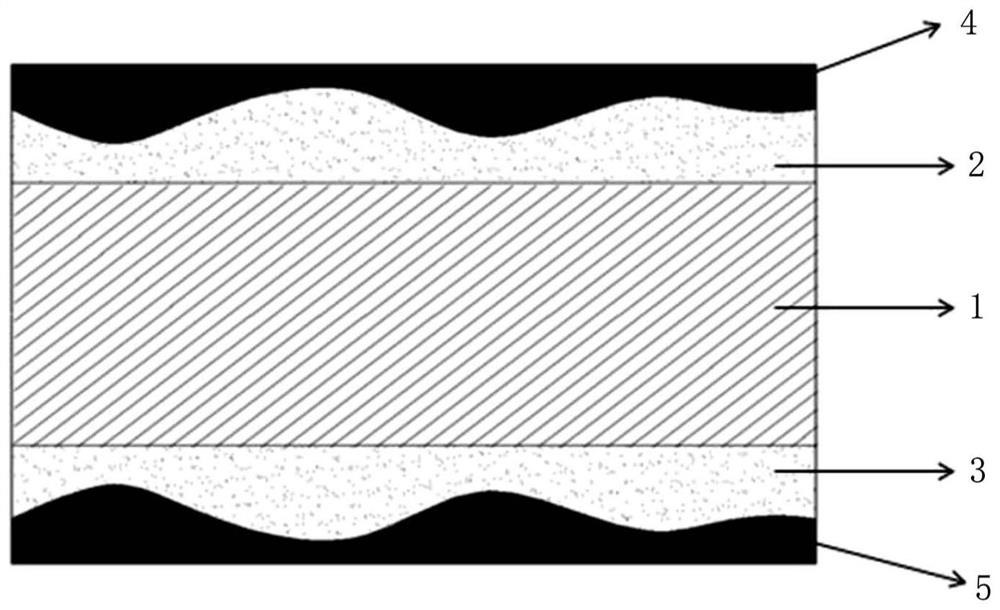

[0017] In order to enable those skilled in the art to better understand the technical concept of the present invention, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, in which the same reference numerals always refer to the same components.

[0018] The reason why the household oil-free fume pot has the effect of no oil fume is to control the temperature of the bottom of the pot within 220 ℃ within a certain period of time, because the cracking temperature of ordinary cooking oil is 220 ℃ ~ 240 ℃, as long as the bottom of the pot exceeds this temperature, it must be Will produce fumes.

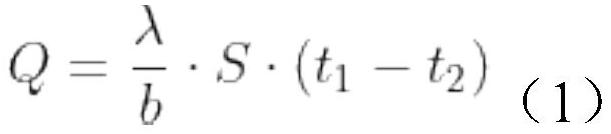

[0019] The heat transfer method of the cookware is mainly heat conduction, which is determined by the flat wall heat conduction formula:

[0020]

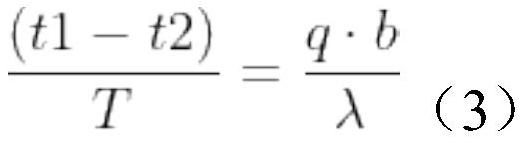

[0021] Among them, Q-heat transfer; λ-material thermal conductivity; b-wall thickness; S-heat transfer area; t1-high temperature surface temperature; t2-low temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com