A knitted elastic underwear with down and a processing method thereof

A technology for knitting elasticity and down, which is applied in the field of down knitted elastic underwear and its processing, can solve the problems of lack of elasticity, inability to fit closely to the human body, and inability to give full play to the thermal insulation properties of down jackets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

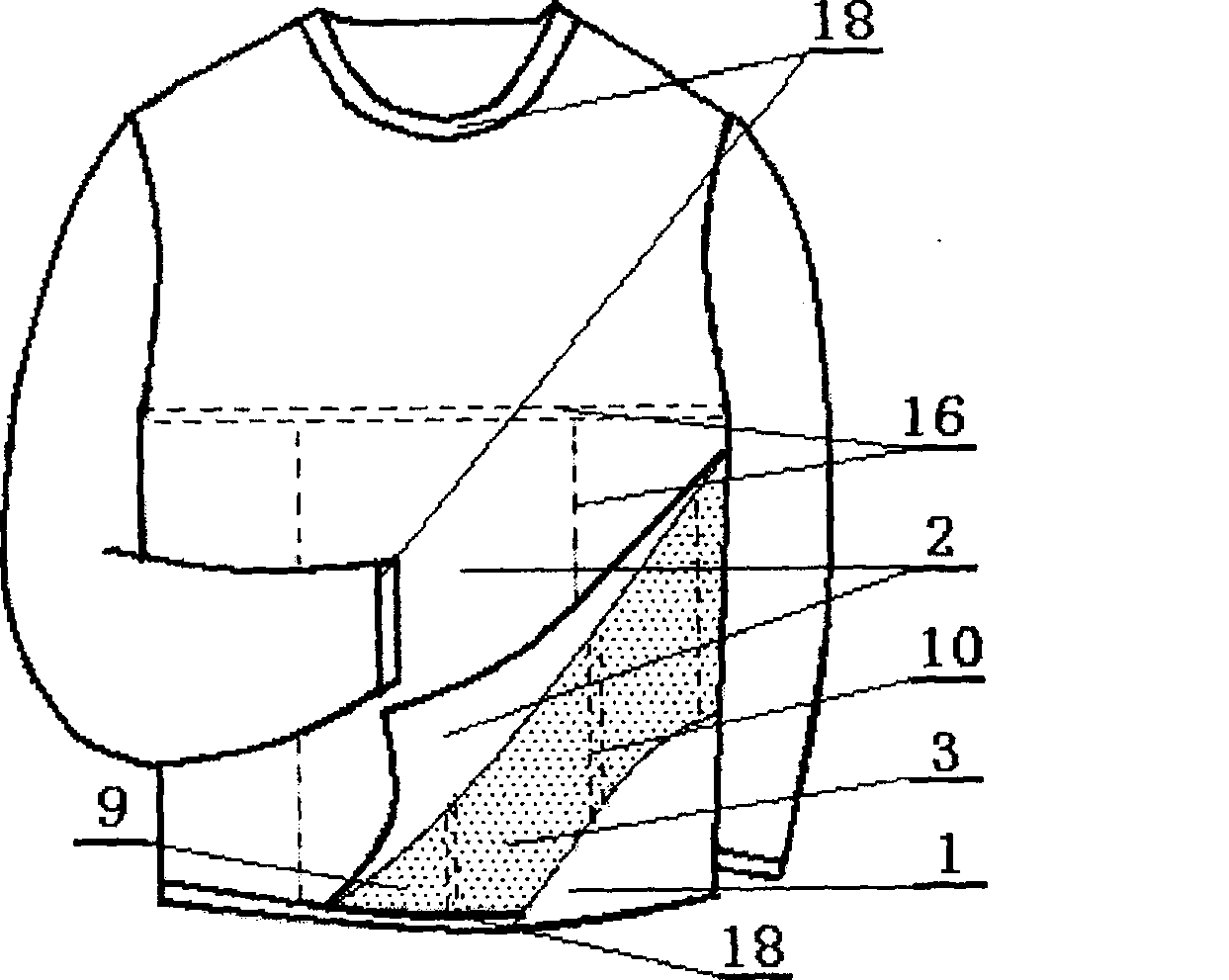

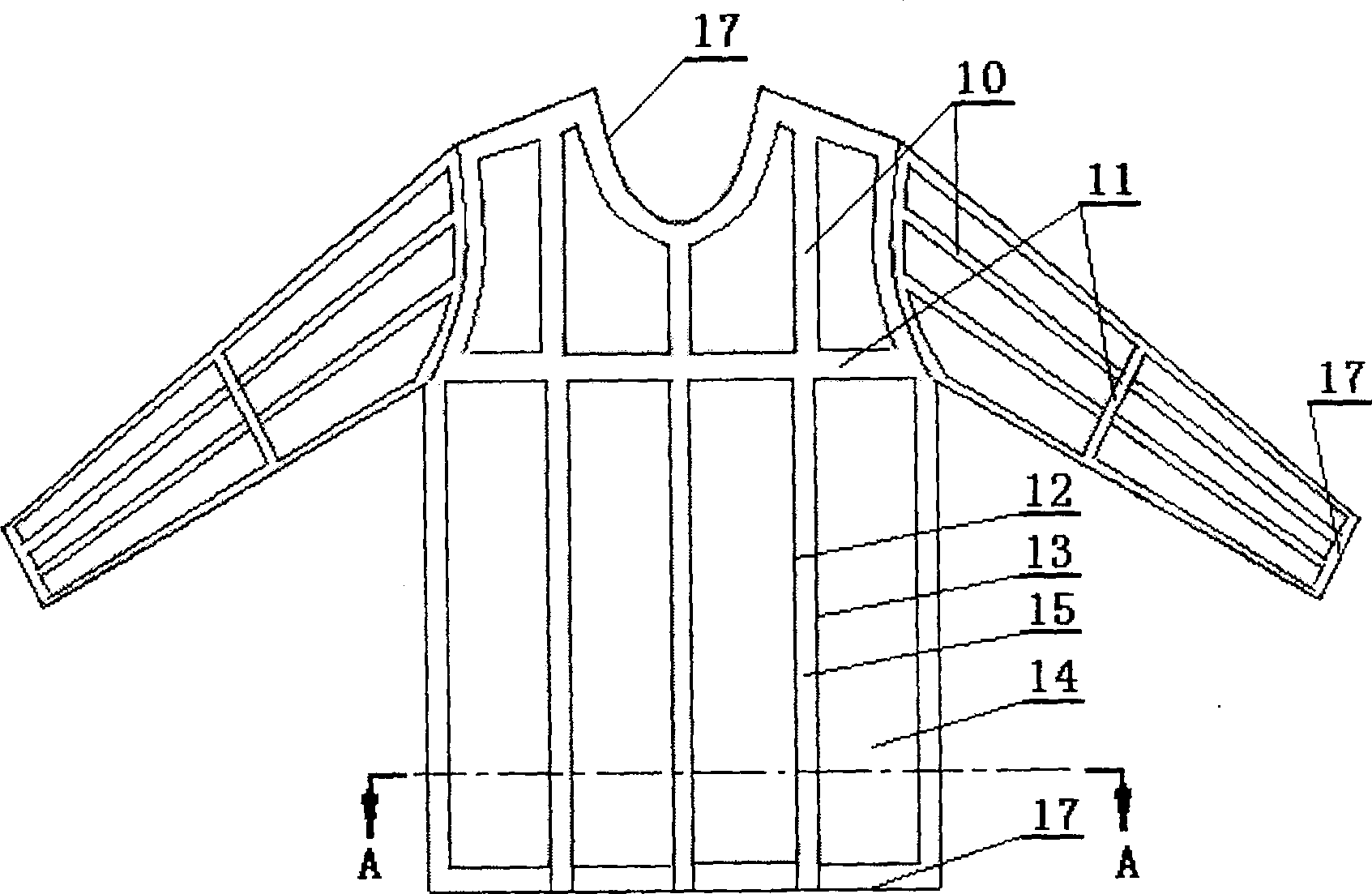

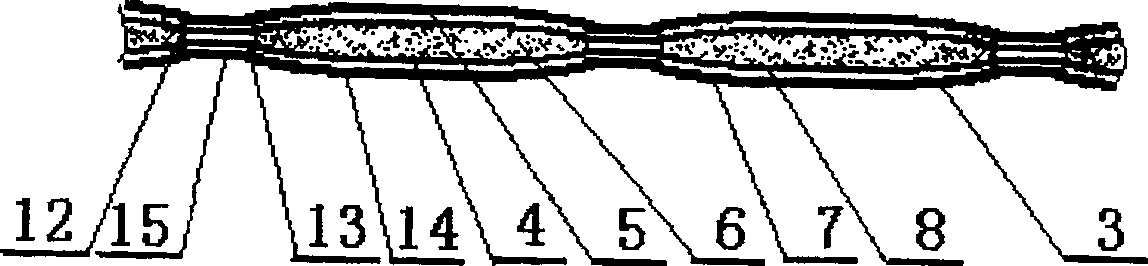

[0019] exist figure 1 , figure 2 and image 3 Among them, the knitted down elastic underwear of the present invention is mainly composed of an inner liner 1 , an outer cover 2 and an inner liner 3 , and the inner liner 3 is arranged between the inner liner 1 and the outer cover 2 . Wherein: the inner lining 1 and the outer cover 2 are made of elastic thin knitted fabrics; the inner tank 3 is composed of inner and outer linings 4, 5 and down feathers 6, and the inner and outer linings 4 and 5 are adhered by barrier layer 7 and ordinary thin non-woven fabric 8 The resulting double-layer composite non-woven fabric is composed of a barrier layer 7 arranged on the outer surfaces of the inner and outer linings 4 and 5, and its main body is arranged on an outer surface of an ordinary thin non-woven fabric 8 by coating, and countless layers are arranged on it. Subtle inverted trumpet hole 9, composed of PU polymer material with dual functions of breathability and blocking down feat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com