Gas adsorption analog simulation method of graphene doped composite material

A gas adsorption, composite material technology, applied in design optimization/simulation, computer material science, instruments, etc., can solve the problems of weak adsorption effect and limit the application of graphene, and achieve the effect of improving the adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

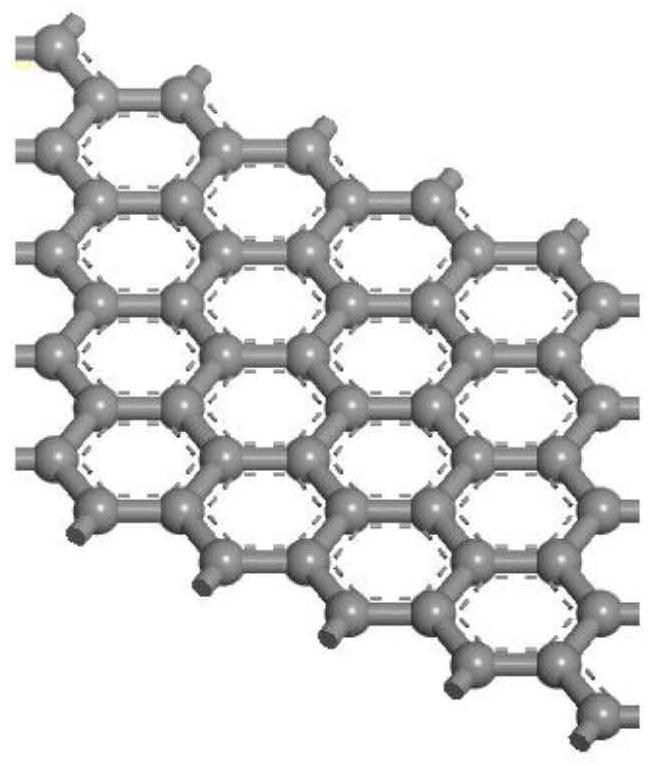

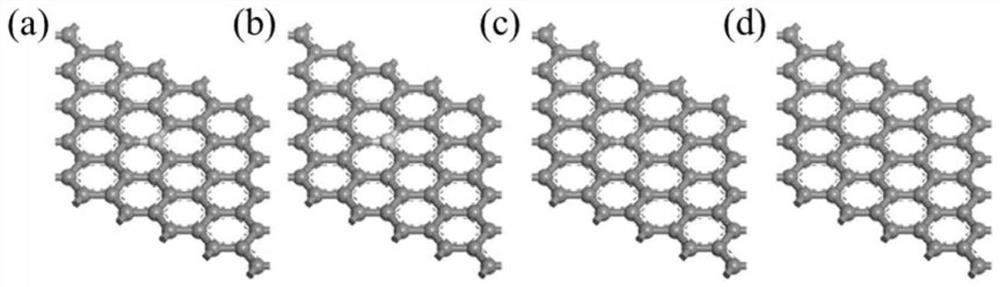

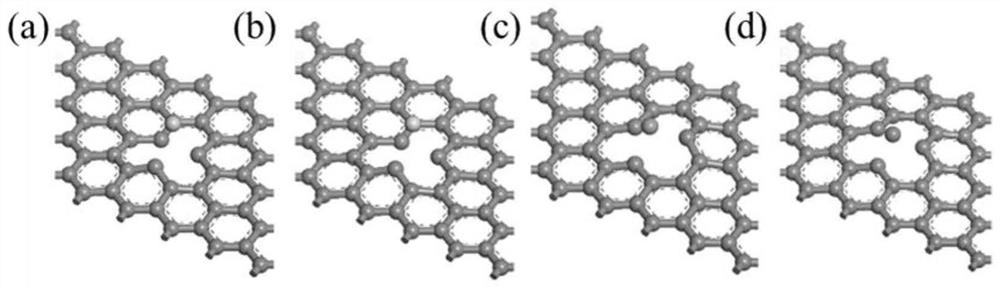

[0033] In this embodiment, simulation software is used to calculate the structure, energy band and density of states of graphene after doping with transition metal elements and the graphene system after adsorbing gas.

[0034] The lattice constant of the graphene original cell is 0.2462 nm, which is extended to a graphene supercell of 5 × 5 × 1. Each primitive cell contains 2 carbon atoms, and the supercell contains a total of 50 carbon atoms. A vacuum layer with a thickness of 2 nm was taken in the direction perpendicular to the graphene layers to avoid graphene interlayer interference. The doping method of transition metal elements is as follows: first remove a carbon atom, and then fill the vacancy of the carbon atom with a doping metal atom. In this way, the energy of the doping system can be minimized as much as possible.

[0035] In th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com