Vertical pumping unit capable of automatically adjusting stroke frequency and balancing

A pumping unit, automatic adjustment technology, applied in the direction of machines/engines, liquid variable capacity machinery, mechanical equipment, etc., can solve the problems of low mechanical efficiency, increased noise, and untimely tracking, etc., and achieve convenient loading and unloading, give way to the effect of convenience

Active Publication Date: 2022-06-21

山东胜信石油装备有限公司

View PDF24 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The balance adjustment at the present stage is adjusted after manual shutdown, and then runs for a period of time to check the balance degree. When the balance is not suitable, stop the well for manual adjustment until the balance degree requirements are met.

The downtime of manual adjustment is long, the labor intensity is high, and the tracking is not timely. It is very necessary to design a vertical pumping unit that can automatically adjust the balance

[0005] The existing mature beamless pumping units include mechanically commutated broadband chain pumping units and electrically commutated rotating motor commutated beamless pumping units. The stroke of the broadband chain commutated pumping unit is a fixed stroke. The transmission chain is long and the mechanical efficiency is low; the patent search for the motor-reversed beamless pumping unit driven by the friction drive of the load belt requires a separate load unloading and load-loss protection mechanism; the patent search for the existing load belt or wire rope winding drive The motor reversing beamless pumping units include "intelligent silent pumping unit", "double-drum beamless pumping unit and its control method", and the "intelligent silent pumping unit" is the outer rotor permanent magnet synchronous The large torque motor is directly driven. In order to meet the driving load of oil pumping, the smaller the diameter of the winding drum, the greater the output force. Therefore, the diameter of the winding drum is selected to be small, so that the belt cannot be directly centered on the wellhead, and the centering front guide wheel group is added to make the load The frequency of belt flexures is doubled, resulting in frequent belt breakage; the "double-drum non-beam pumping unit and its control method" is a structure in which the motor drives the reducer to drive the rollers, and the reducer has increased noise after running for a long time. Large and hidden dangers of oil leakage; and the existing vertical pumping units do not have the function of automatically adjusting stroke times and balance. times and balance function, the present invention creatively proposes automatic adjustment of times and balance vertical pumping unit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

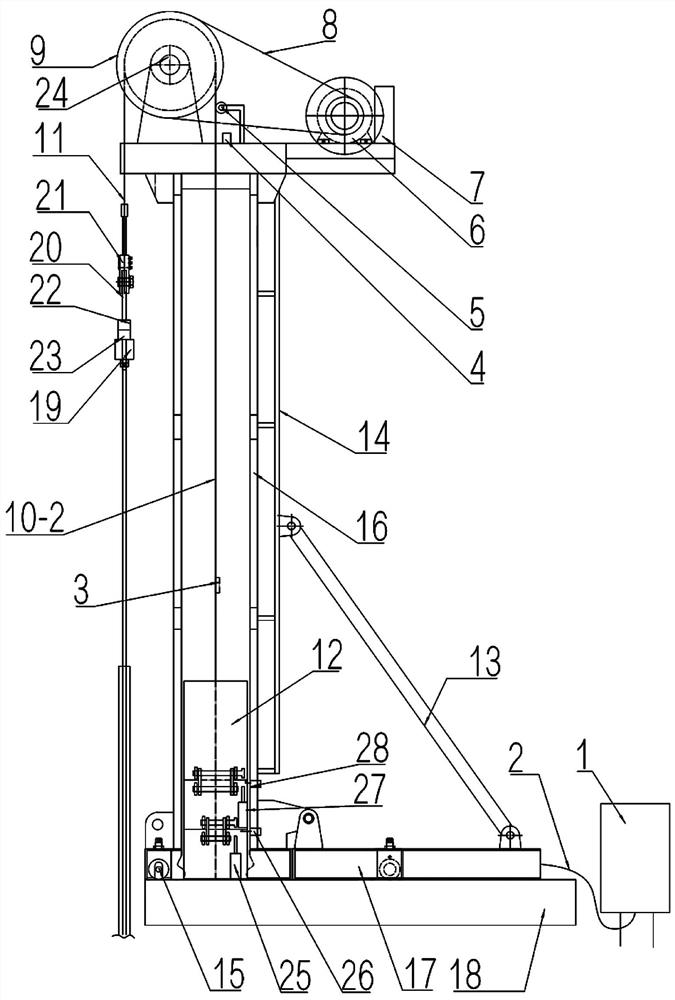

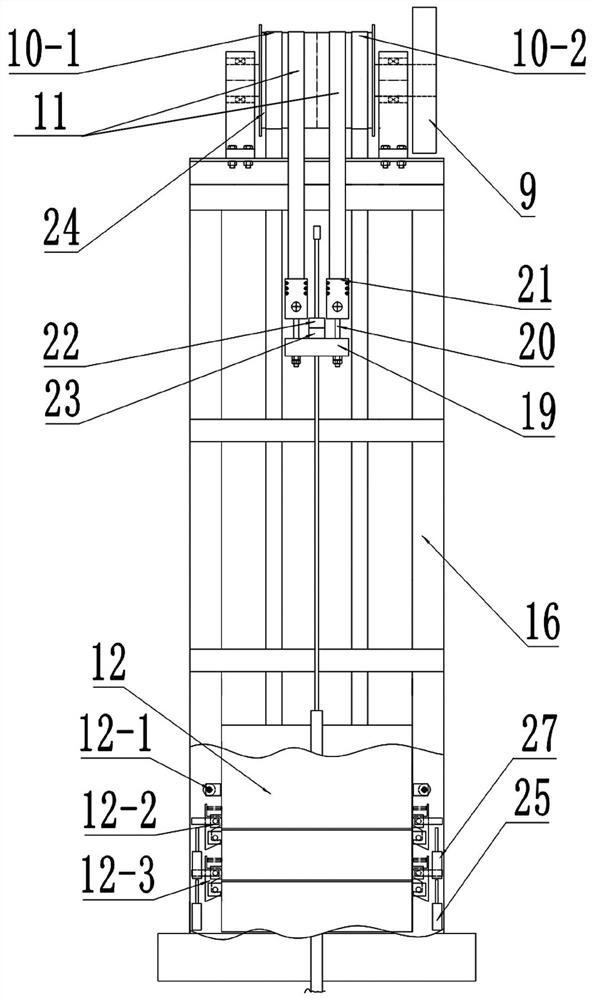

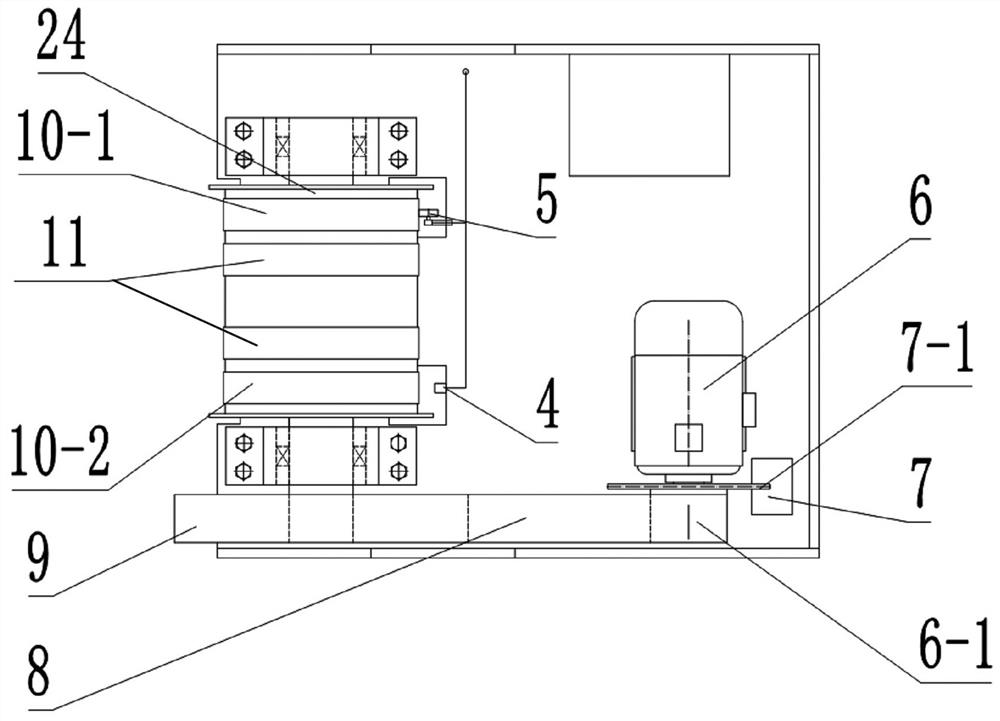

A vertical pumping unit capable of automatically adjusting stroke frequency and balancing belongs to the technical field of oil field oil extraction equipment and comprises a motor, a motor synchronous pulley, a power-off brake, a synchronous belt, a roller synchronous pulley and a roller which are mounted on a platform at the upper end of a rack, the other group is that a weight box lifting belt I and a weight box lifting belt II are connected with a weight box, the weight box is provided with an automatic balance adjusting executing mechanism composed of a picking and hanging mechanism and an electromagnetic push rod, and a logic controller of a control cabinet controls a motor to rotate forwards and backwards according to the up-and-down displacement of the lifting belts, so that reciprocating motion of a set stroke is achieved; the balance degree is calculated according to the torque, the weight box is automatically disassembled or combined to adjust the balance degree, the stroke frequency is automatically adjusted according to the wellhead load transmitted by the wireless load sensor, whether load loss and shutdown protection are carried out or not is judged according to the feedback power of the energy feedback unit, and the oil extraction device is ideal oil extraction equipment with mechanical and electrical integration and high intellectualization.

Description

technical field [0001] The invention belongs to the technical field of oil production equipment in oilfields, in particular to a vertical pumping unit with automatic flushing adjustment and balance. Background technique [0002] The pumping unit is the lifting equipment for oil production in the oil field. Due to the needs of deep wells and heavy oil, the proportion of vertical pumping units is increasing. The beamless pumping unit can basically realize the non-stop adjustment of the stroke frequency, and can manually adjust the speed of the up and down; however, the existing pumping unit cannot automatically adjust the stroke frequency. Viscosity of heavy oil changes greatly from the early stage to the end stage, resulting in a large change in the downward resistance of the oil well to the polished rod, often causing the pumping unit to run at a lower speed than the polished rod and shut down due to the super-unilateral lifting force. ; while the upward operation of the pu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E21B43/00F04B47/14H02K7/10H02K7/102

CPCE21B43/126F04B47/14H02K7/102H02K7/1004

Inventor 卢同辉孙培增宋玉全常国旭

Owner 山东胜信石油装备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com