Electromagnetic pump

A technology of electromagnetic pumps and pump trenches, applied in the field of electromagnetic pumps, can solve the problems of large amount of materials used, high cost, and difficult heat dissipation structure design, and achieve the effect of improving flow and efficiency and reducing circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make those skilled in the art better understand the solutions of the present invention, the technical solutions in the specific embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

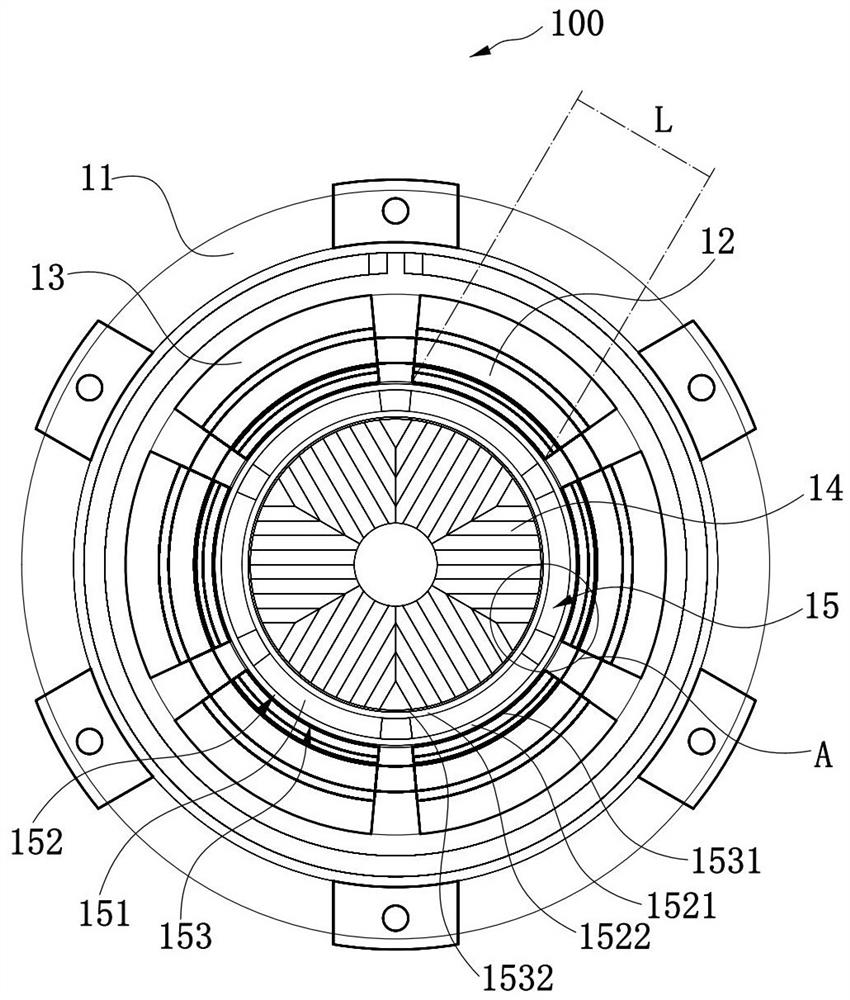

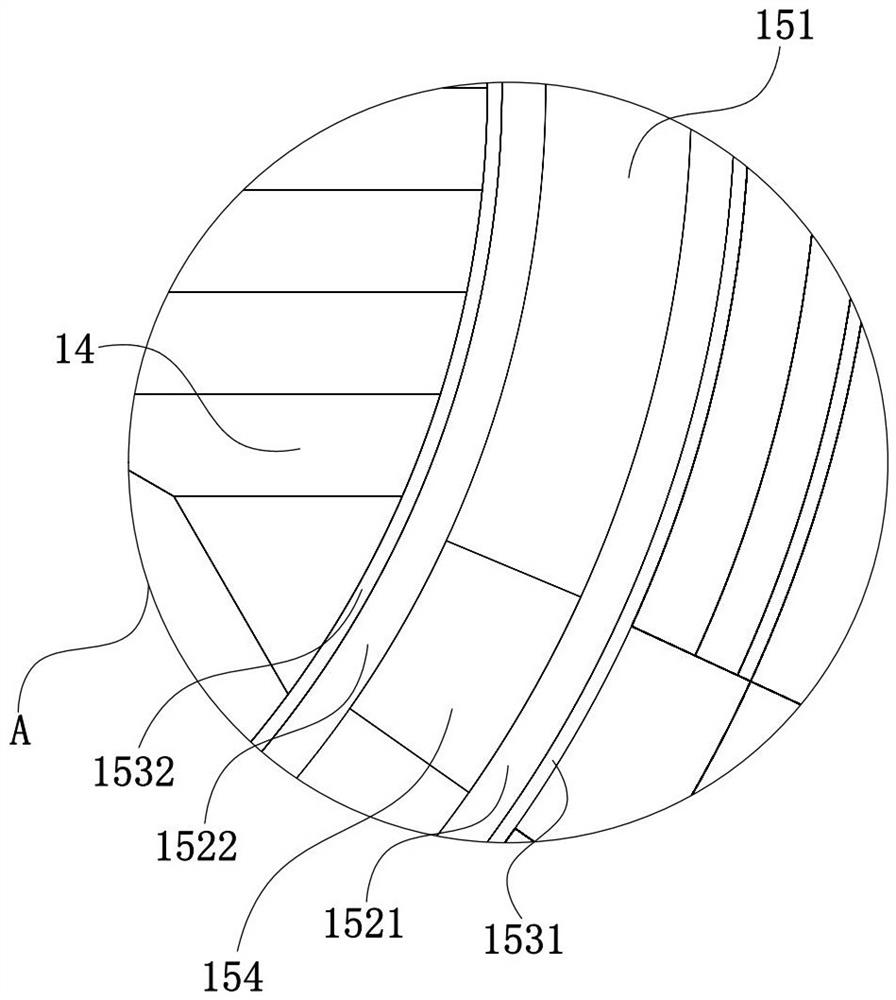

[0058] like figure 1 As shown, an electromagnetic pump 100 includes a pump body 11 , a winding 12 , a plurality of outer iron cores 13 , an inner iron core 14 and a pump groove mechanism 15 . The pump body 11 is formed with a first accommodating space. The winding 12 is at least partially arranged in the first accommodating space, and the winding 12 is at least partly arranged on the outer iron core 13 for delivering current. The plurality of outer iron cores 13 are at least partially disposed in the first accommodating space, and the inner iron cores 14 are also at least partially disposed in the first accommodating space. The plurality of outer iron cores 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com