Preparation process of environment-friendly board based on camphorwood and pine

A preparation process, a technology of camphor wood, which is applied in the direction of wood processing appliances, manufacturing tools, and the joining of wooden veneers, can solve the problem of low connection strength, and achieve the effects of stable fixed structure, increased strength, and tight fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

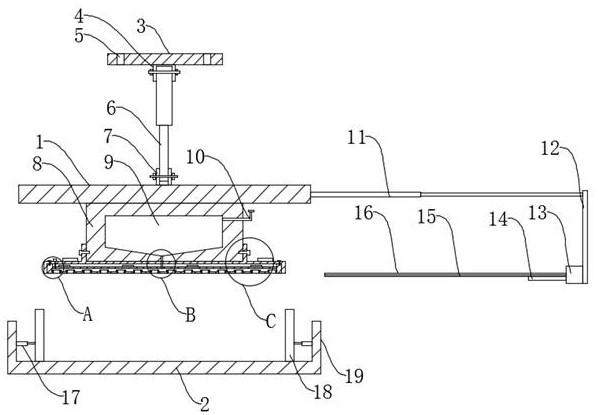

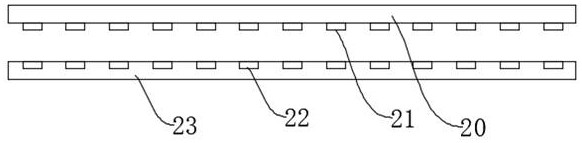

[0052] The present invention provides such as Figure 1-5 Shown a kind of environmental protection board preparation technology based on camphor wood and pine wood, comprises the following steps:

[0053] S1: Prepare raw materials, prepare wood sandwich skin, pine wood, camphor wood and EO environmentally friendly glue, according to the volume ratio, prepare: pine wood 60%-70%, camphor wood 20% to 30%, wood sandwich skin 10%-20% ;

[0054] S2: Paving and pressing, the camphor wood and pine wood are paved and pressed by pressing equipment to form an environmentally friendly board;

[0055] In S2, the surface of camphor wood and pine wood is embossed by pressing equipment, and the embossing between camphor wood and pine wood is closely attached to each other when they are pressed and fixed;

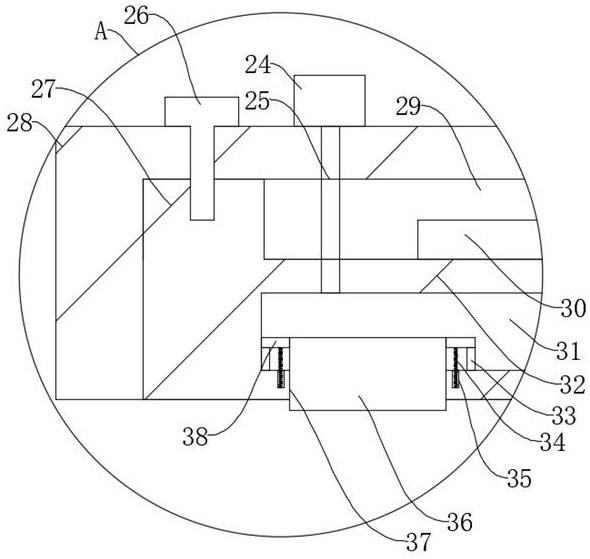

[0056] In S2, the pressing equipment includes an upper substrate 1, a lower substrate 2 is arranged below the upper substrate 1, a lower convex portion 8 is integrally provided on the bot...

Embodiment 2

[0078] The present invention provides such as Figure 1-5 Shown a kind of environmental protection board preparation technology based on camphor wood and pine wood, comprises the following steps:

[0079] S1: Prepare raw materials, prepare wood sandwich skin, pine wood, camphor wood and EO environmentally friendly glue, according to the volume ratio, prepare: pine wood 60%-70%, camphor wood 20% to 30%, wood sandwich skin 10%-20% ;

[0080] S2: Paving and pressing, the camphor wood and pine wood are paved and pressed together by pressing equipment to form an environmentally friendly board;

[0081] In S2, embossing is carried out on the surface of camphor wood and pine wood by means of pressing equipment, and the embossing between camphor wood and pine wood is closely attached to each other when they are pressed and fixed;

[0082] In S2, the pressing equipment includes an upper substrate 1, a lower substrate 2 is arranged below the upper substrate 1, a lower convex portion 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com