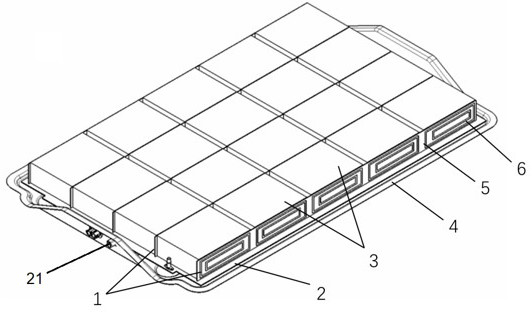

Battery hybrid heat exchange device and battery pack

A heat exchange device and battery technology, which is applied to secondary batteries, circuits, electrical components, etc., to achieve the effects of improving temperature consistency, simple structure, and uniform battery temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

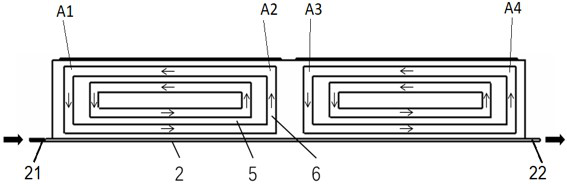

[0048] Continue to refer to image 3 , the reason why the refrigerant 6 will flow in this way, in addition to the heat absorption and heat release of the refrigerant 6 itself, another important reason is that along the direction of the metal plate 5, the liquid cooling circuit 2 forms a Temperature difference. like image 3 As shown, the heat conducting plate 1 has four positions A1, A2, A3, and A4 along the length direction of the liquid cooling circuit 2, and the corresponding temperatures are T1, T2, T3, and T4 respectively. Since the liquid cooling circuit 2 is always exchanging heat with the heat conduction plate 1, under the heating condition, the temperatures of the four positions A1, A2, A3, and A4 from high to low are T1>T2>T3>T4 respectively. Due to the temperature difference, in the closed circuit, the refrigerant 6 releases heat at the position A2 and absorbs heat at the position A1. Similarly, refrigerant 6 releases heat at position A4 and absorbs heat at posit...

Embodiment 2

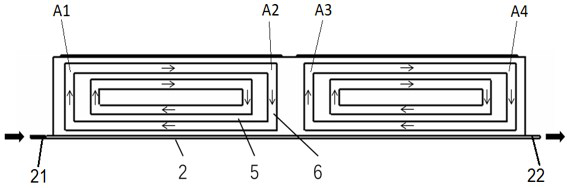

[0059] At the same time, a part of the honeycomb closed circuit of the heat conduction plate 1 away from the inlet 21 of the liquid cooling circuit 2, that is, a part of the refrigerant 6 in the metal plate 5 is at a position far away from the inlet 21 of the liquid cooling circuit 2, and this part of the refrigerant 6 flows to the battery module 3 Release heat, convert from gaseous state to liquid state and fall down the closed circuit (pipeline), such as Figure 5 indicated by the down arrow.

[0060] Similar to Embodiment 1, in this embodiment, the refrigerant 6 forms a flow in the honeycomb closed circuit, and during the flow process, the refrigerant 6 simultaneously transforms between liquid and gas. During the cyclic heat absorption and heat dissipation process of vaporization and liquefaction, the refrigerant 6 quickly releases the heat of the battery module 3 to the liquid cooling circuit 2, thereby ensuring efficient heat dissipation of the power battery and a stable ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com