Industrial equipment fault detection method with time series state variable

A technology of time series and industrial equipment, applied in neural learning methods, comprehensive factory control, instruments, etc., can solve problems such as difficult application of methods and difficulty in obtaining fault data, and achieve high practicability, strong universality, and strong self-control The effect of adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

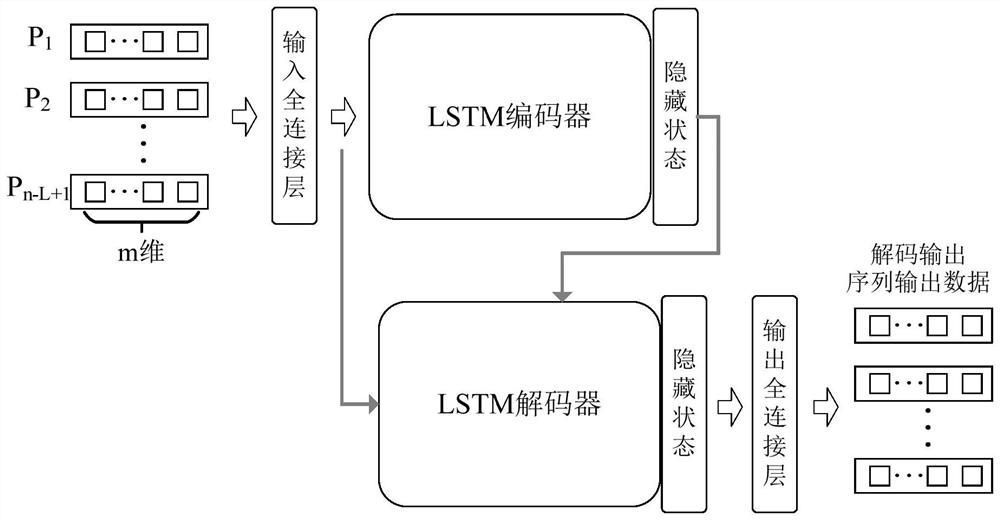

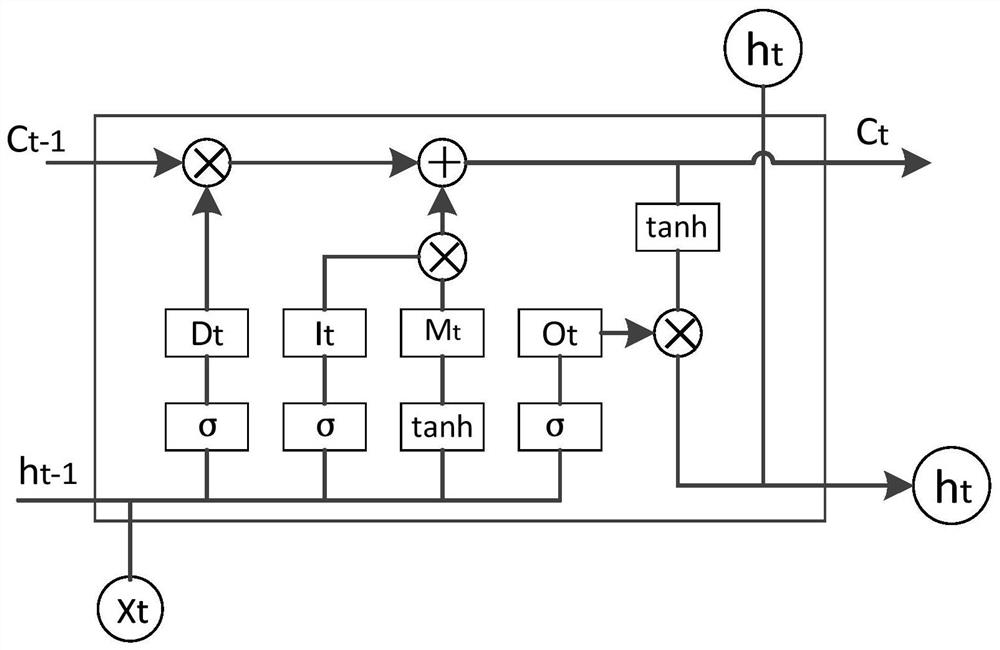

[0063] Specific implementation mode 1. Combination Figure 1 to Figure 4 As shown, the present invention provides a fault detection method for industrial equipment with time-series state variables, including:

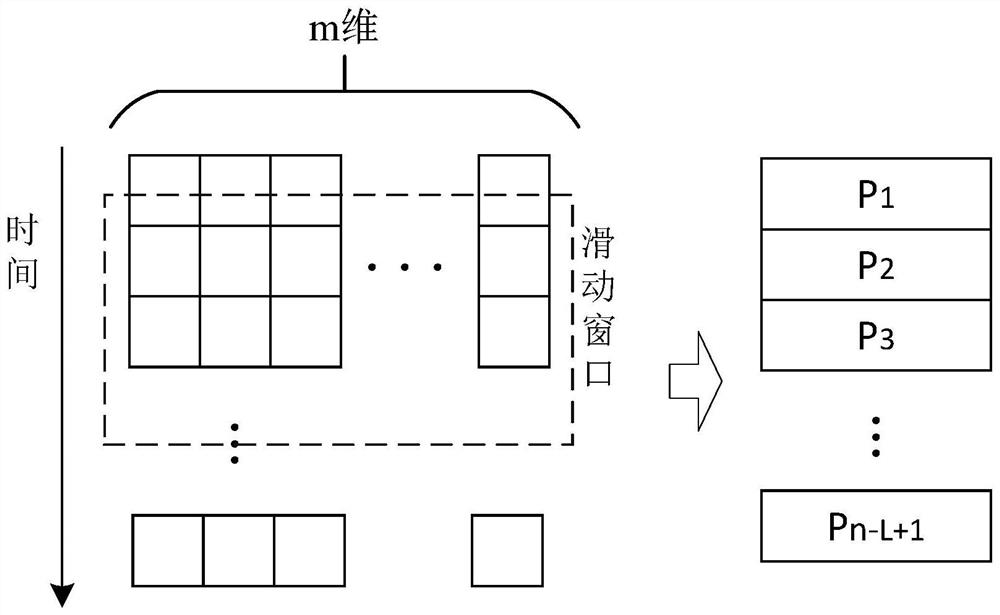

[0064] The time series state data of n times during normal operation of industrial equipment is collected as training data with a set step size, and the training data at each moment includes m-dimensional feature variables, where m is the total number of feature variables of industrial equipment;

[0065] Calculate the mean μ and standard deviation σ of the m-dimensional feature variables of the training data, and standardize all training data at each moment to obtain standardized time series data;

[0066] Using a sliding window with a preset length of L to divide the normalized time series data to obtain n-L+1 sequence data P with a length of L;

[0067] The sequence data P is used to train the LSTM self-encoding network to obtain the sequence output data; the sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com