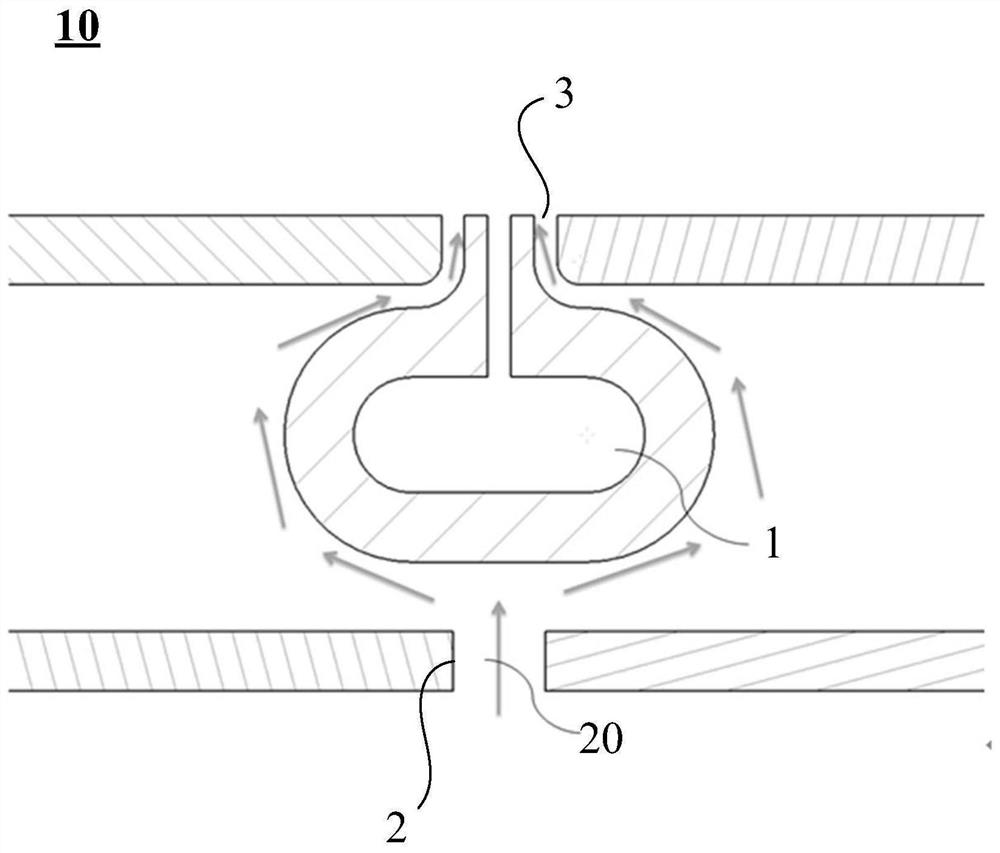

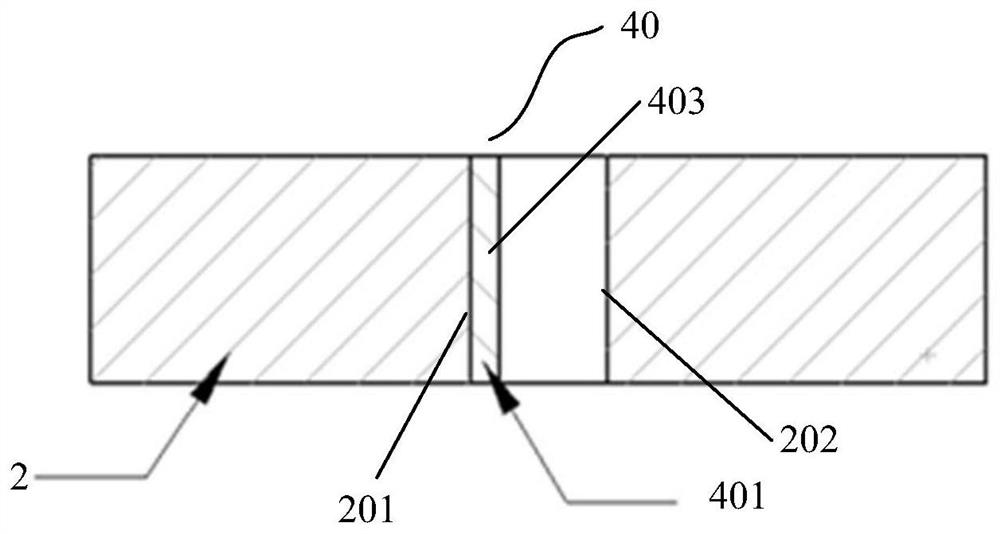

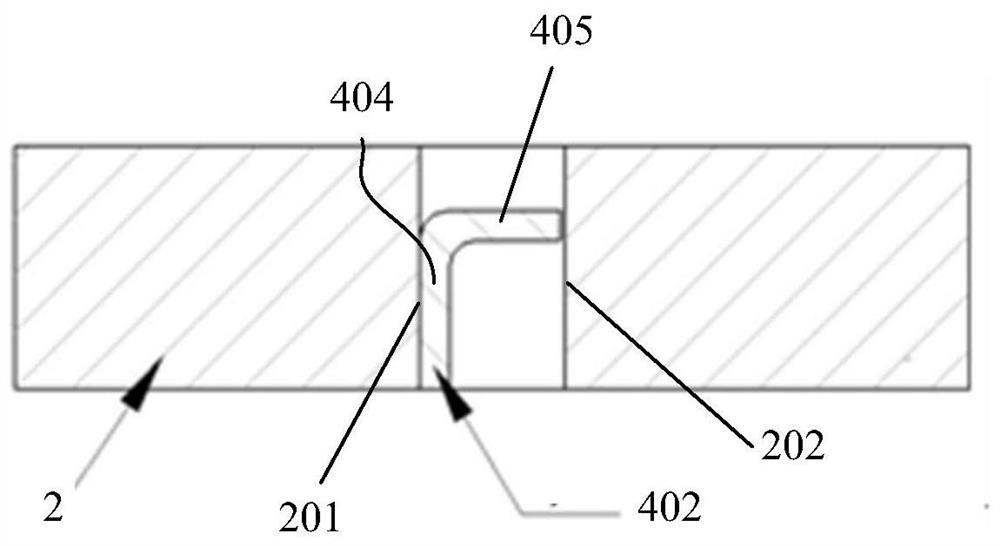

Fuel nozzle, combustion chamber, gas turbine engine and method for preventing coking of fuel

A technology of fuel nozzles and oil passages, applied in combustion methods, gas turbine devices, combustion chambers, etc., can solve the problems of increasing the operating cost of gas turbine engines and short maintenance periods, and achieve reduced coking risks, reduced operating costs, and strong reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below with reference to specific embodiments and accompanying drawings. More details are set forth in the following description to facilitate a full understanding of the present invention, but it is obvious that the present invention can be implemented in many other ways that are different from those described herein. Those skilled in the art can make similar promotion and deduction according to the actual application situation without violating the connotation of the present invention, so the content of this specific embodiment should not limit the protection scope of the present invention.

[0038] In addition, it is to be understood that references such as "one embodiment," "an embodiment," and / or "some embodiments" mean a certain feature, structure, or characteristic associated with at least one embodiment of the present application. Therefore, it should be emphasized and noted that two or more references to "an embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com