Downward layered drift filling mining method for extremely-broken thick and large ore body

A technology of thick and large ore body and access filling, applied in underground mining, filling, surface mining, etc., can solve the problems of ore loss and dilution rate, unsafe mining personnel, collapse, etc., and reduce loss and dilution. efficiency, improved mechanization, and sufficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

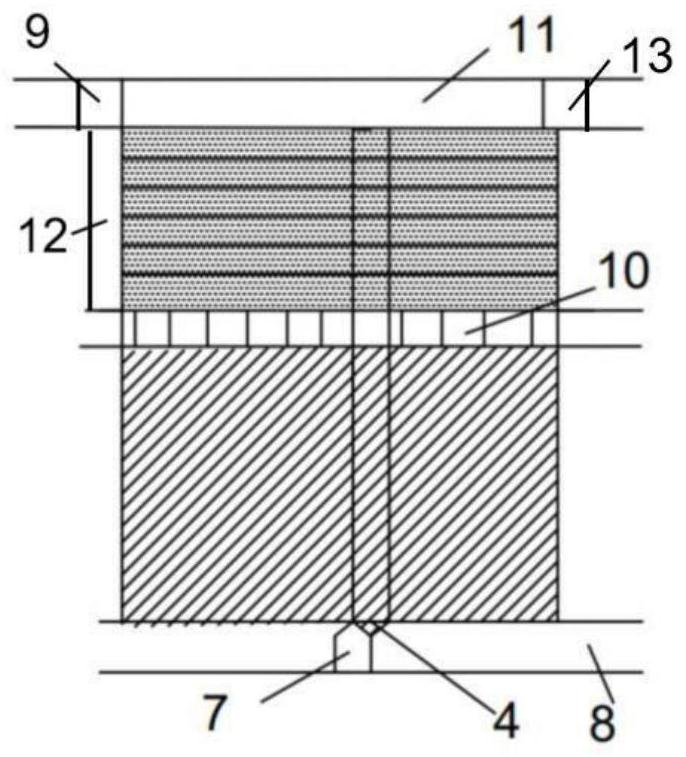

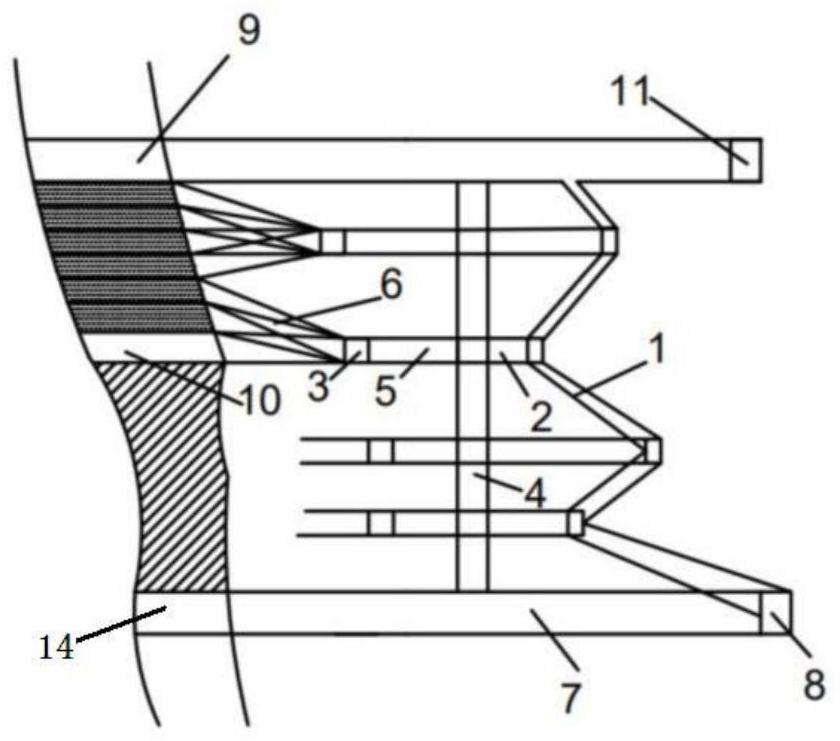

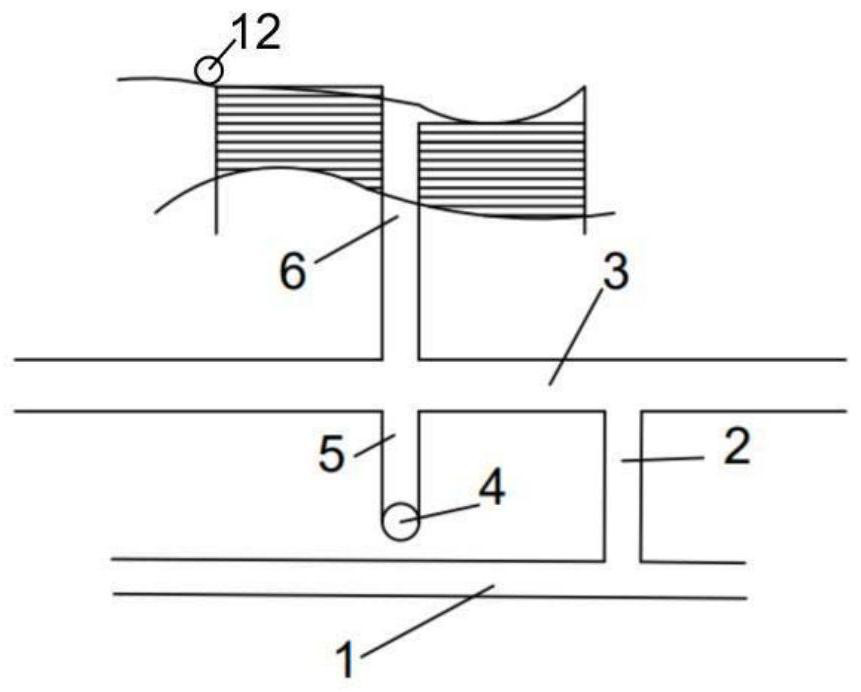

[0025] The content of the present invention will now be further described with reference to the figures and examples.

[0026] like figure 1 , figure 2 , image 3 As shown in the figure, a method for backfilling and mining of extremely broken thick and large ore bodies with a downward stratified approach, the method comprises the following steps:

[0027] S1: Stope layout: In this embodiment, the ore blocks are arranged along the strike, the length of the ore blocks is 50m, and the width of the ore body is 20m on average. Because it is an approach mining, there are no intervening pillars, top pillars and bottom pillars, and the stage height is high. It is 35m, divided into 4 sections, each section has a height of 8m, and is divided into 4 layers, and the height of each stope layer is 2m.

[0028] S2: Precise cutting: excavate a 3m×3m outer slope 1 between the adjacent middle sections perpendicular to the vein, connect each stage roadway at the outer slope 1, and excavate a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com