Spare and accessory part anti-collision treatment device for wholesale of spare and accessory parts

A technology for processing devices and spare parts, applied in the directions of external parts and internal parts, etc., can solve problems such as low use efficiency, inability to place a large number of parts, etc., and achieve the effect of preventing falling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

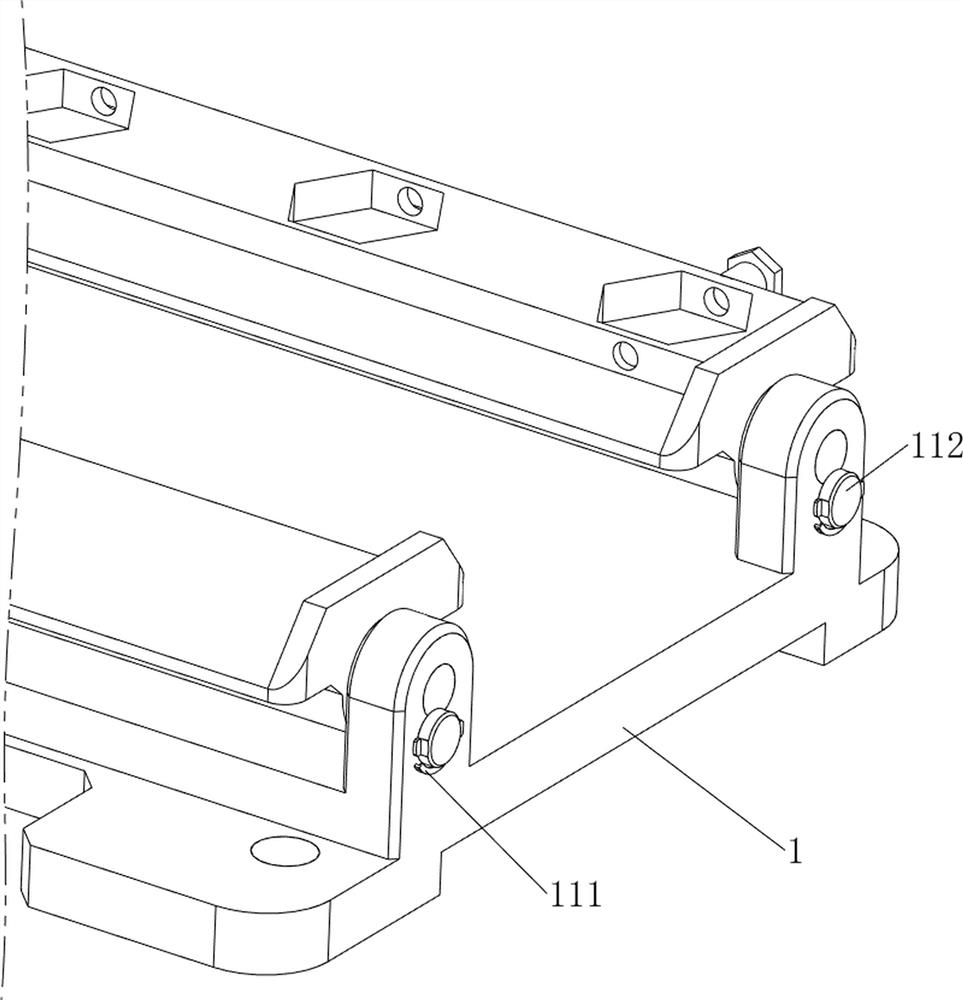

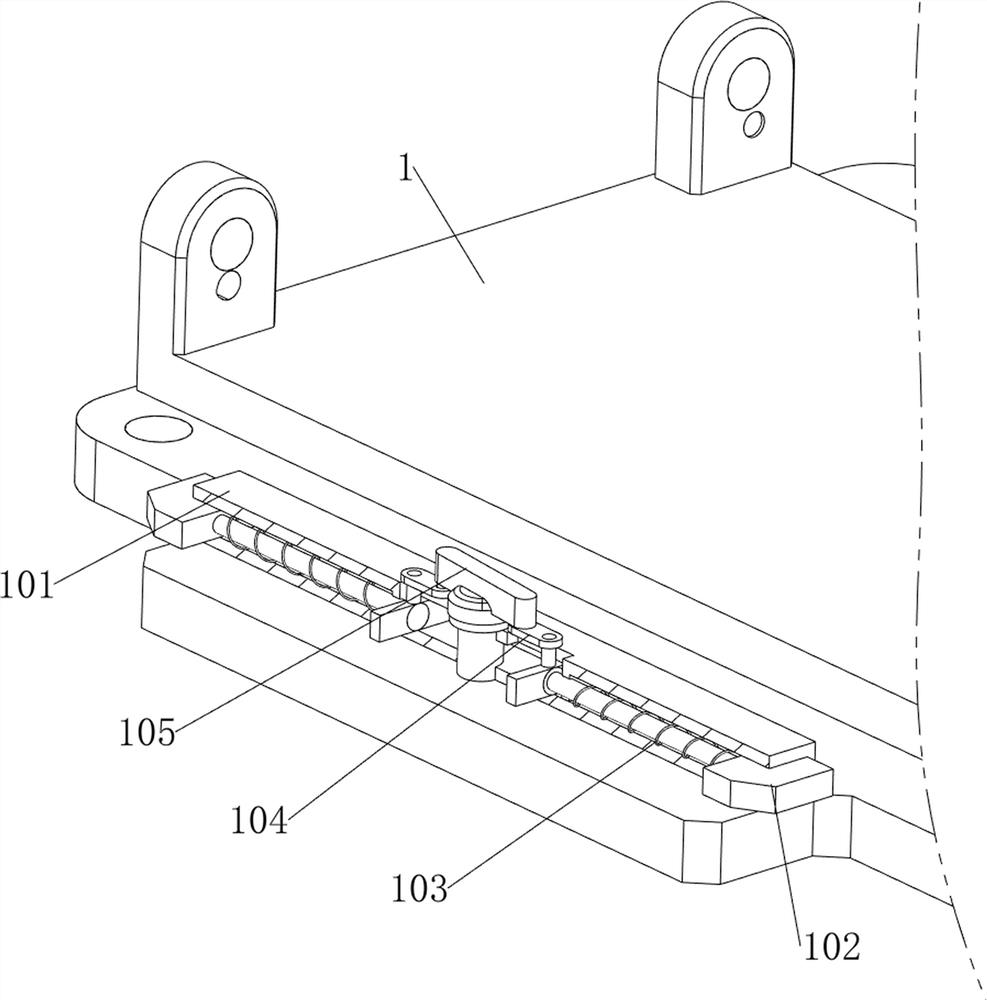

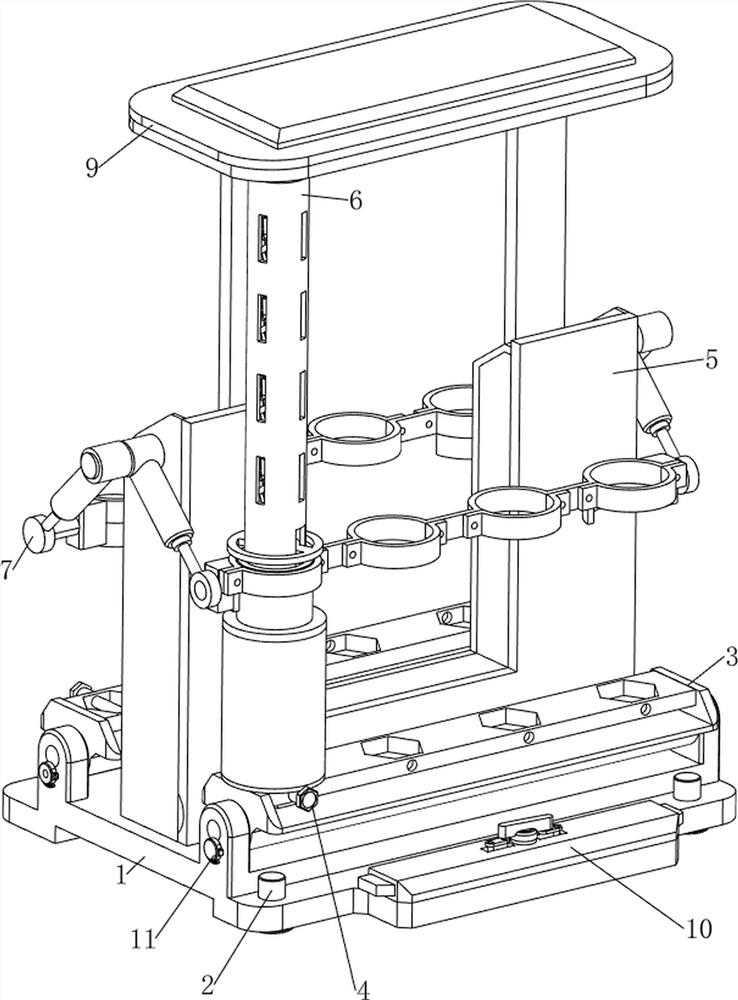

[0034] An anti-collision processing device for spare parts for wholesale of spare parts, such as Figure 1-6 As shown, it includes a base 1, a suction cup 2, a turret 3, a first fixing bolt 4, a first connecting plate 5, a support mechanism 6 and a rotating mechanism 7. The four corners of the upper side of the base 1 are provided with suction cups 2, and the suction cups 2 The stability of the device can be improved. The left and right sides of the upper part of the base 1 are rotatably connected with a turret 3. The turret 3 is convenient for people to take out and place the spare parts. The front side of the right part of the turret 3 is provided with a removable first fixing bolt. 4. There is a first connecting plate 5 in the middle of the upper side of the base 1. The first connecting plate 5 can separate the left turret 3 and the right turret 3 to prevent the placed parts from colliding, and the right turret 3 The front side is provided with a support mechanism 6, which ...

Embodiment 2

[0039] On the basis of Example 1, as Figure 7 , Figure 8 and figure 2 As shown, it also includes an unfolding mechanism 8 capable of unfolding and storing spare parts. The unfolding mechanism 8 includes a second fixing rod 81, a second sliding tube 82, a first connecting rod 83, a second fixing bolt 84, a first fixing rod The block 85, the first rotating rod 86, the torsion spring 87 and the second connecting rod 88, a second fixing rod 81 is provided in the middle of the inner top wall of the first sliding tube 62, and a second sliding tube 82 is provided in the middle of the upper side of the bearing plate 64, Three second sliding pipes 82 are slidably connected to the second fixing rod 81 , and four second fixing bolts 84 are arranged on the upper side of the second sliding pipes 82 along the circumferential direction. The connecting rod 83 and the second fixing rod 81 are evenly provided with four first fixing blocks 85 , and the first fixing blocks 85 are rotatably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com