Machining device for motor output shaft

A processing device and output shaft technology, which is applied to grinding drive devices, metal processing equipment, grinding/polishing safety devices, etc., to facilitate collection and processing and ensure cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

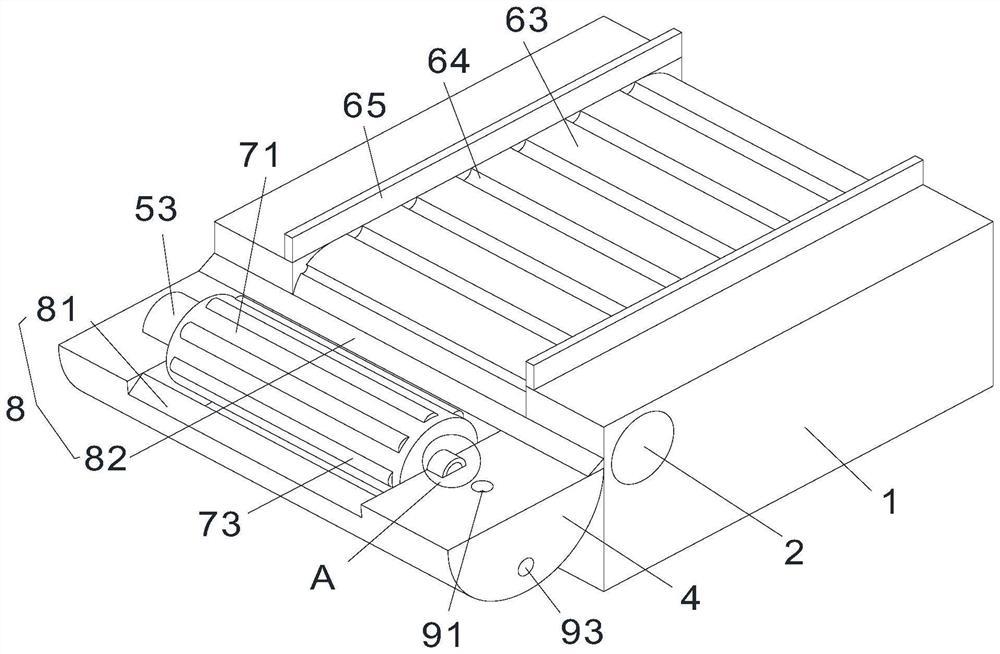

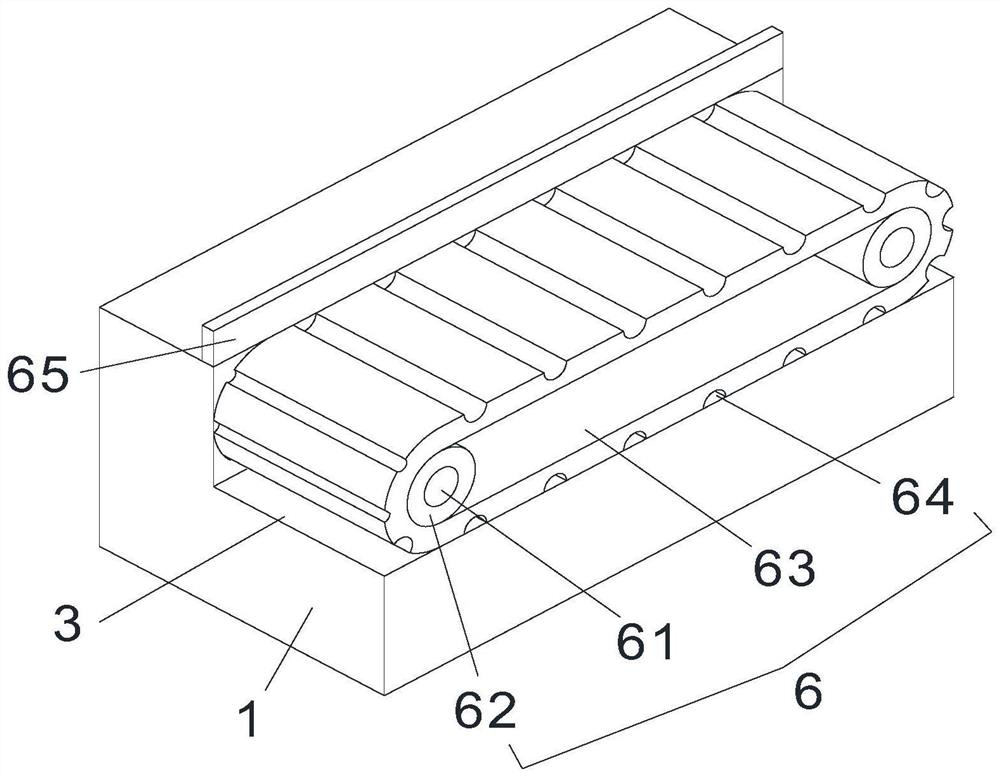

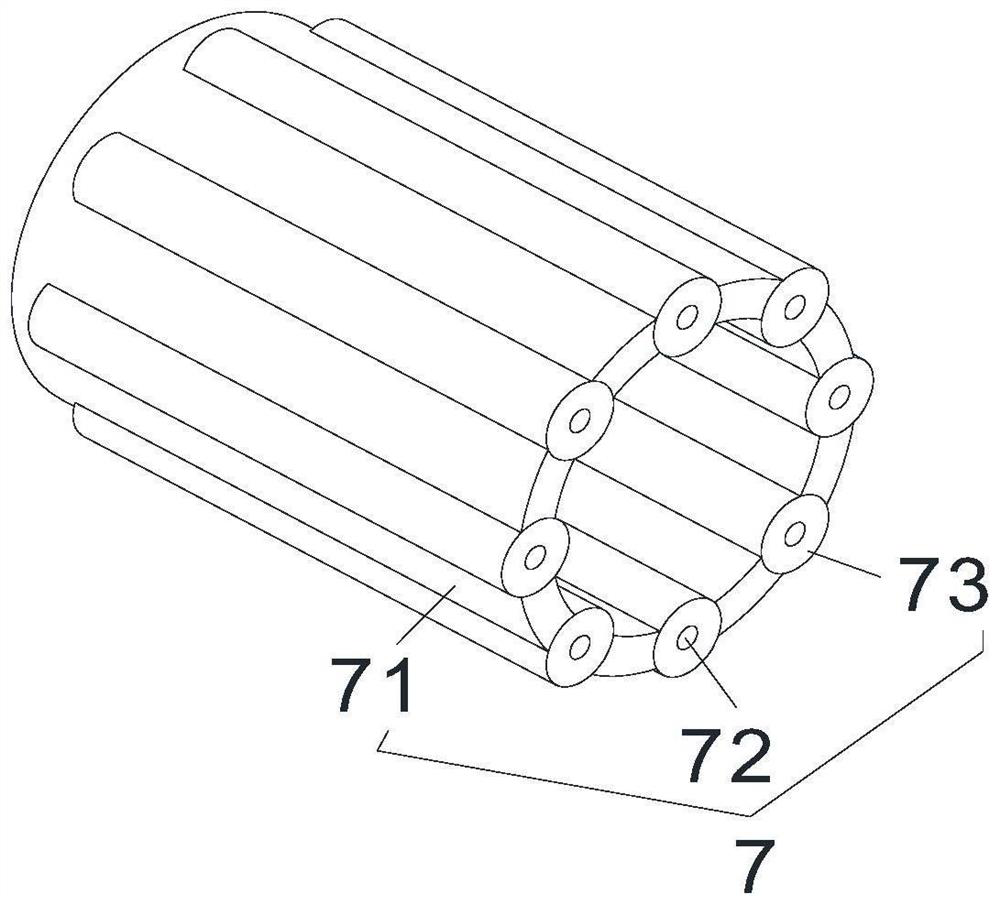

[0035] Example 1: as Figure 1-4 and Figure 7-8 As shown, a processing device for motor output shaft includes a body 1, a feeding motor 2, a placement processing mechanism 4, a driving mechanism 5 and a transmission mechanism 6, and a processing mechanism 7 is arranged inside the feeding motor 2, and the upper The feeding motor 2 is provided with an unloading mechanism 8, and the transmission mechanism 6 is used to cooperate with the feeding motor 2 to transport the output shaft of the motor to be processed to the placement and processing mechanism 4 for processing and cleaning. When the motor output shaft is cleaned, the cleaned waste is cleaned to one side, and the cleaning device 10 is used to cooperate with the processing mechanism 7. The cleaning device 10 will be synchronously driven to operate when the processing mechanism 7 is in operation, thereby The wastes in the placement and treatment mechanism 4 are accumulated to one side of the placement and treatment mechani...

Embodiment 2

[0042] Embodiment 2: on the basis of Embodiment 1, refer to Figure 5-Figure 6 , the inside of the placement processing mechanism 4 is also provided with an injection and discharge mechanism 9, the injection and drainage mechanism 9 includes a liquid injection port 91, the liquid injection port 91 is a hole of a circular truncated structure, and the liquid injection port 91 is opened on the right side of the top wall surface of the placement processing mechanism 4 On the side, the injection and discharge mechanism 9 also includes a liquid inlet groove 92, the liquid inlet groove 92 is a cylindrical inclined groove, the liquid inlet groove 92 is opened in the interior of the placement processing mechanism 4, and the bottom of the liquid inlet groove 92 is connected with the processing groove 41. The top of the liquid inlet tank 92 is communicated with the liquid injection port 91. The right side wall surface of the placement processing mechanism 4 is provided with a liquid disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com