Electronic equipment frame

A technology of electronic equipment and frame, applied in the field of consumer electronics, can solve the problems of high cost, increased thickness of the whole machine, limited flexibility of the frame, etc., and achieves the effect of low cost, short working hours, and avoiding false detection of the air tightness of the glue line.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

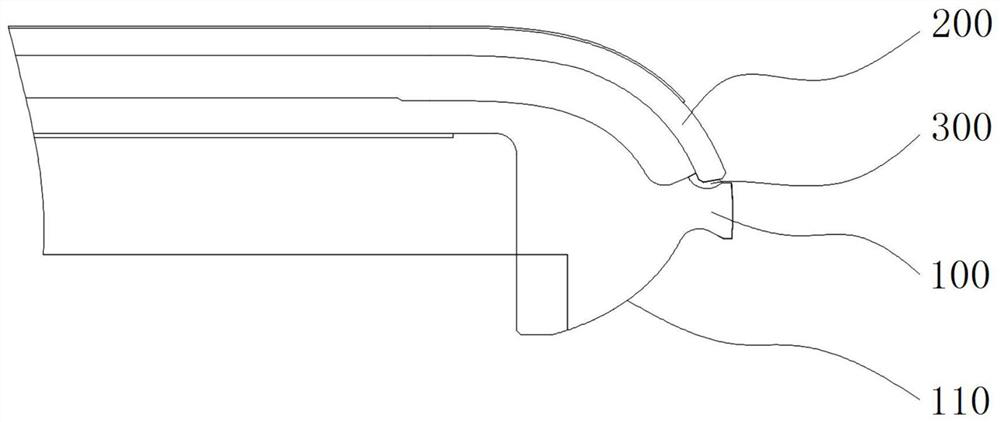

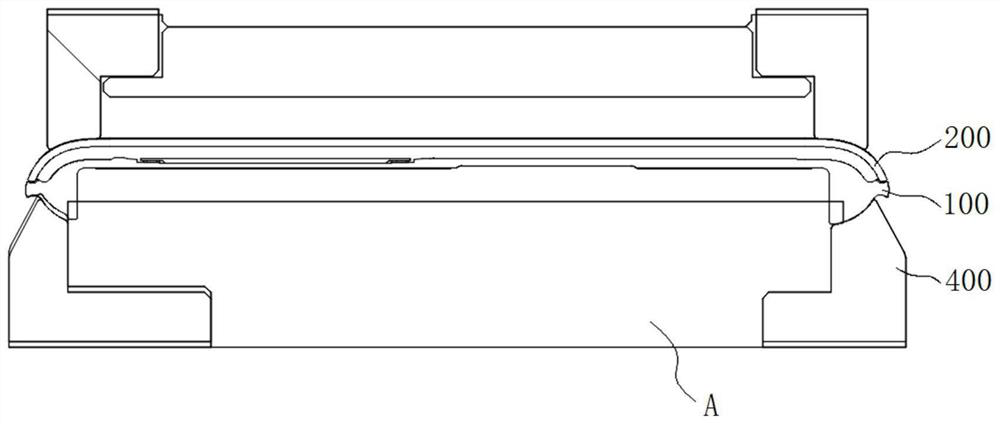

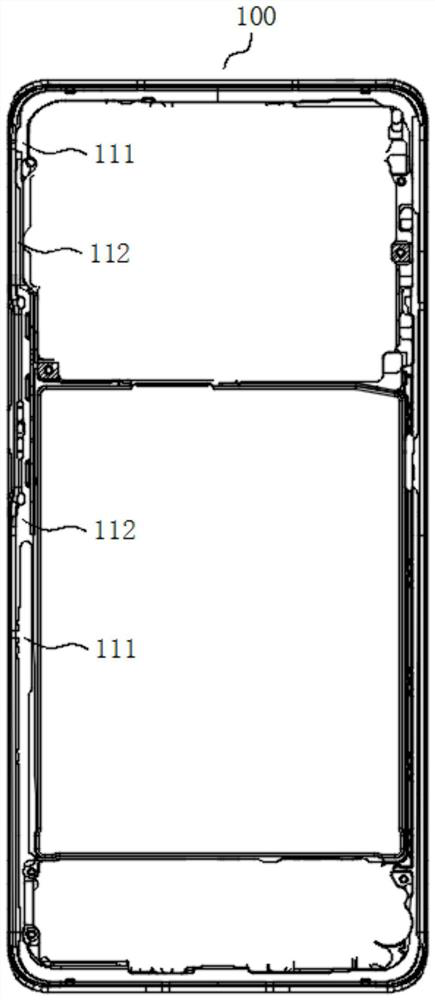

[0032] First please refer to figure 1 , the display screen 200 of the smart terminal product is usually bonded to the top surface of the fuselage frame 100 through the glue line 300 , and the rear shell is bonded to the bottom surface of the fuselage frame 100 . The intelligent terminal product may specifically be a mobile phone, and may also be a watch, a tablet, or the like. The glue line 300 needs to be tested for airtightness to ensure that the glue line 300 is bonded continuously without breakpoints. When testing for air tightness, such as figure 2 As shown, the frame 100 bonded with the display screen 200 cooperates with the fixture 400 to form a closed space A, and a certain air pressure (positive pressure or negative pressure) is applied to the closed space A through the equipment. After the air pressure stabilizes to a certain value, the pressure is maintained for a period of time. Time, such as 5-10s, to detect the air pressure change in the closed space A, to det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com