Capacitor structure and preparation method thereof, semiconductor structure and preparation method thereof

A capacitor structure and semiconductor technology, which is applied in semiconductor/solid-state device manufacturing, capacitors, semiconductor devices, etc., can solve the problems of difficult reading/writing of capacitance, decline of unit capacitance storage capacity, and affecting DRAM performance, etc., to achieve increased area, weakening mutual contact, and increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

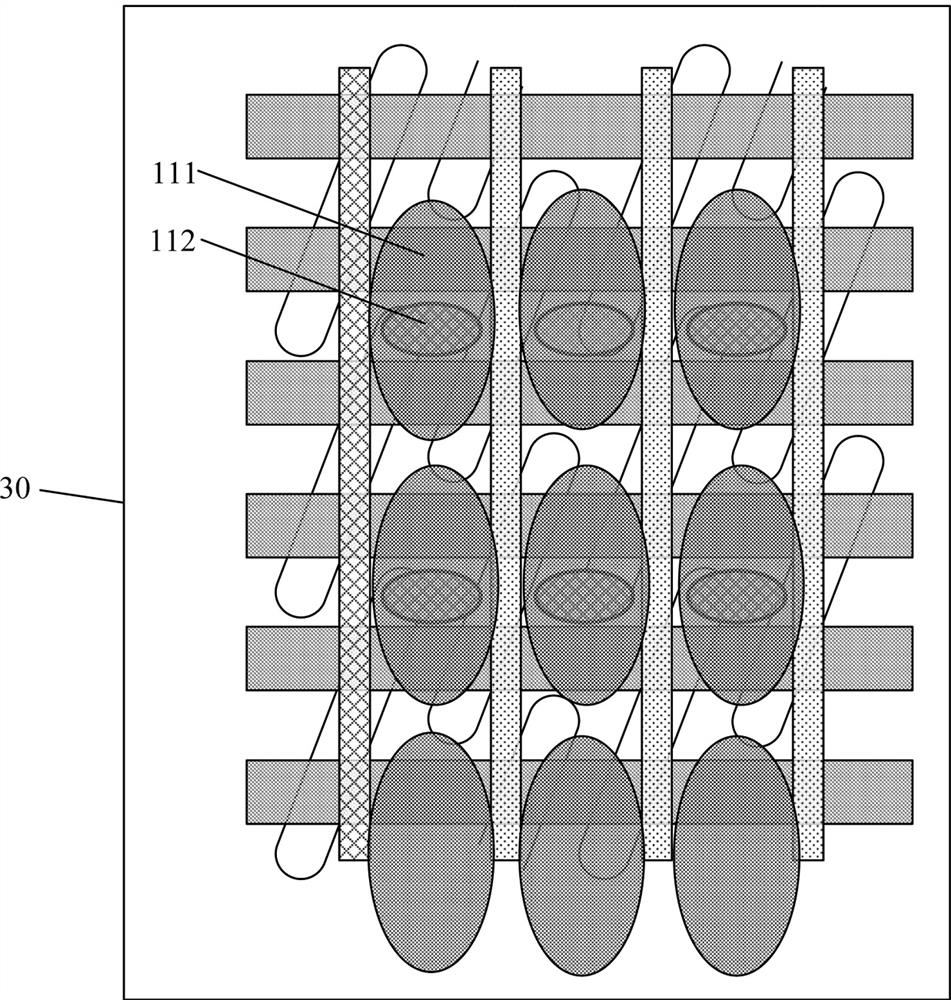

[0143] Embodiments of the present disclosure also provide a method for fabricating a capacitor structure. For details, please refer to the appendix. Figure 8 , as shown, the method includes the following steps:

[0144] Step 801: forming a first insulating layer on the substrate;

[0145] Step 802: forming a first mask on the first insulating layer;

[0146] Step 803 : forming a first through hole in the first insulating layer according to the first mask;

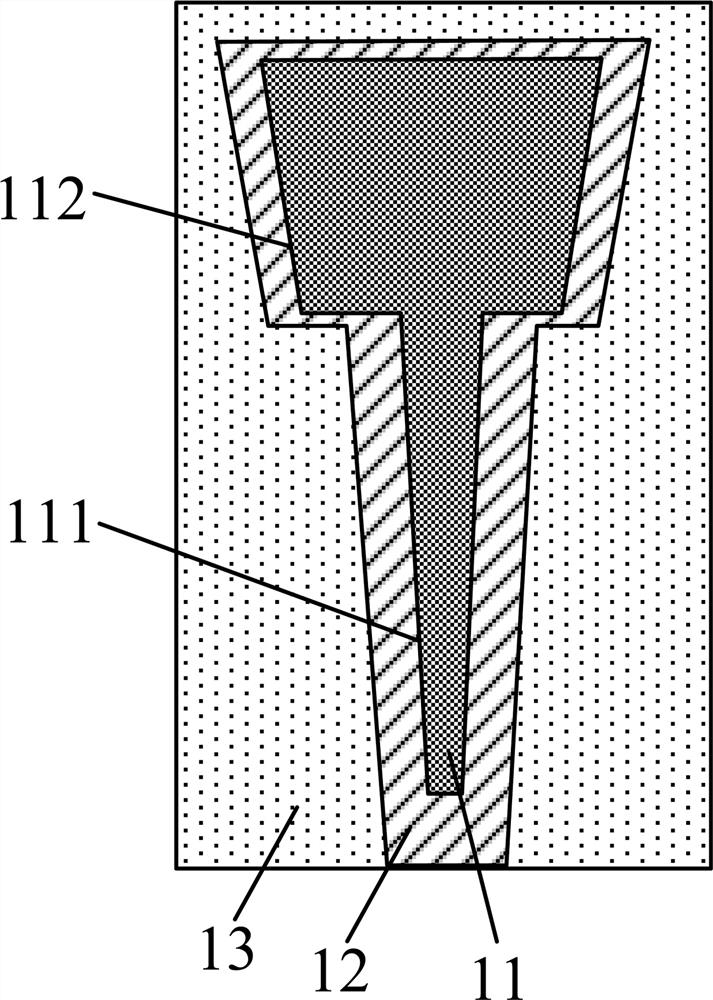

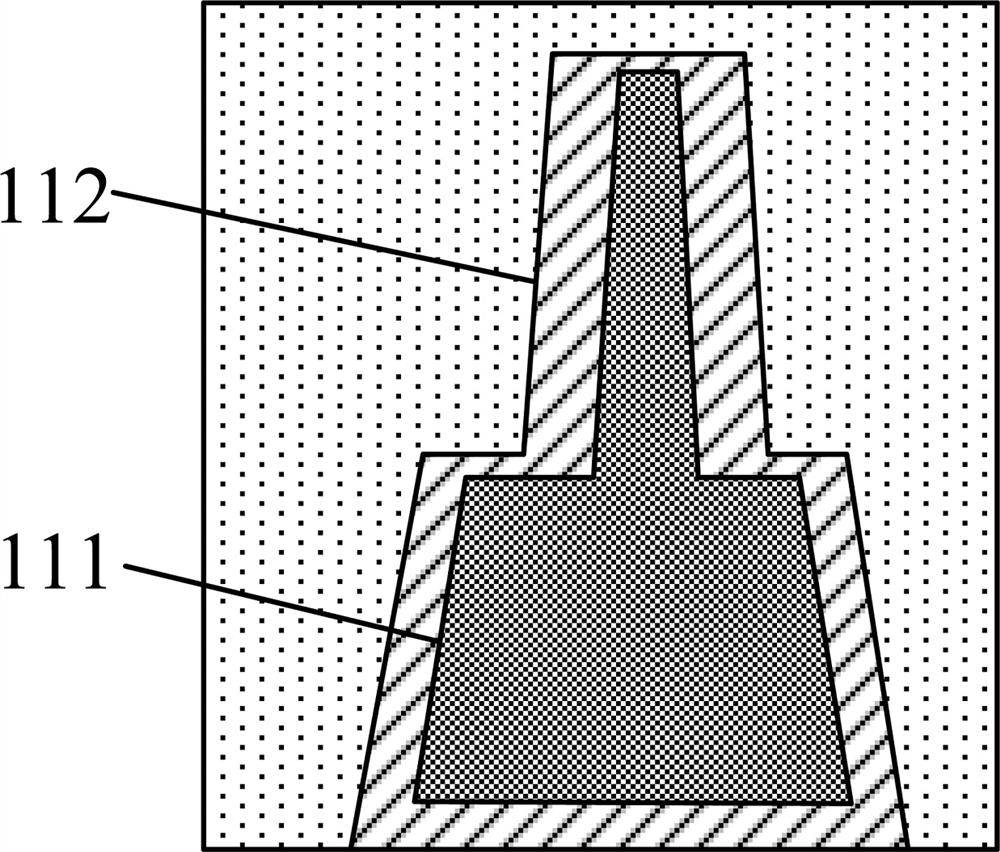

[0147] Step 804 : forming a first sub-electrode of the capacitor structure in the first through hole;

[0148] Step 805 : forming an Nth insulating layer, and forming an Nth mask on the Nth insulating layer, where N is greater than or equal to 2;

[0149] Step 806: Form an Nth through hole in the Nth insulating layer according to the Nth mask, and the Nth through hole and the N−1th through hole are connected in a direction perpendicular to the substrate. , among the N through holes, the orthographic projection of at le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com