Capacitor and preparation method and installation method thereof

A capacitor and circuit board technology, applied in the field of capacitors, can solve the problems of high space height of vertical capacitors, complicated welding process of capacitors, large manual operation errors, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

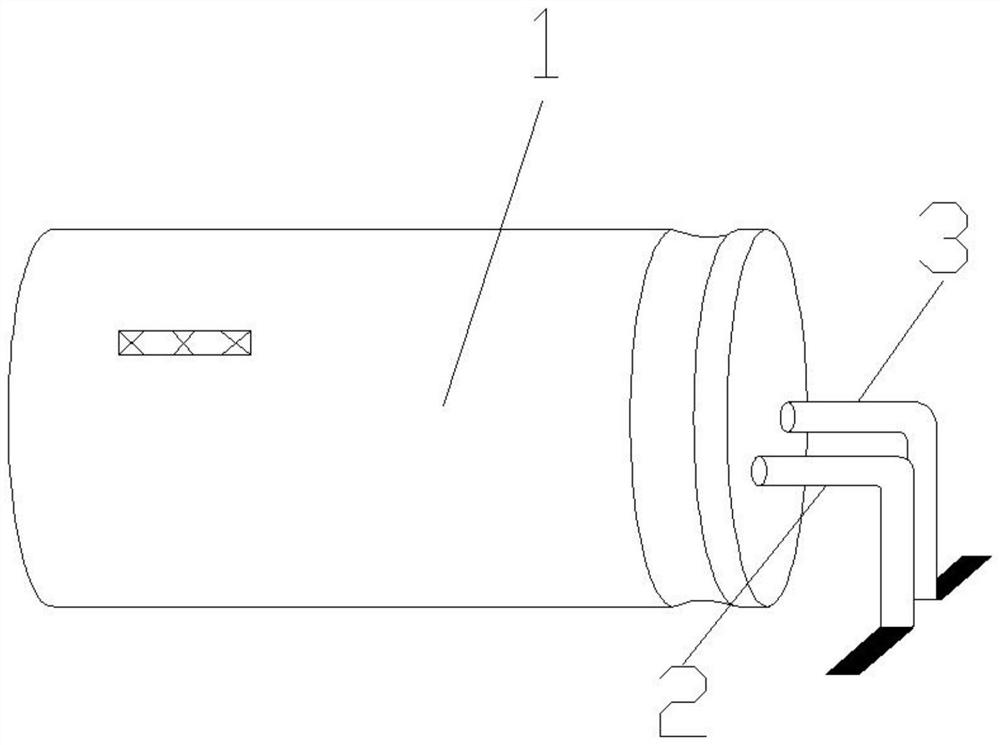

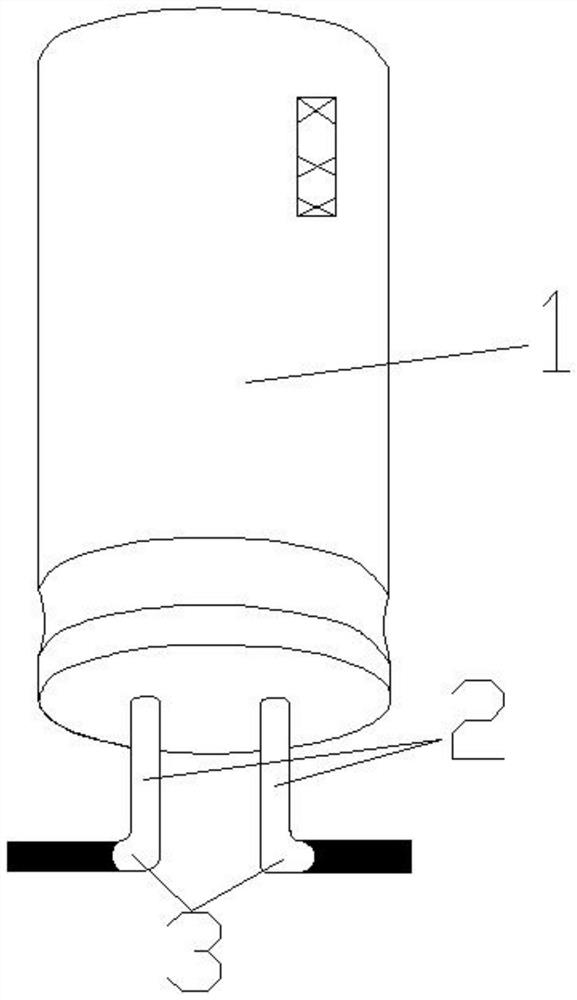

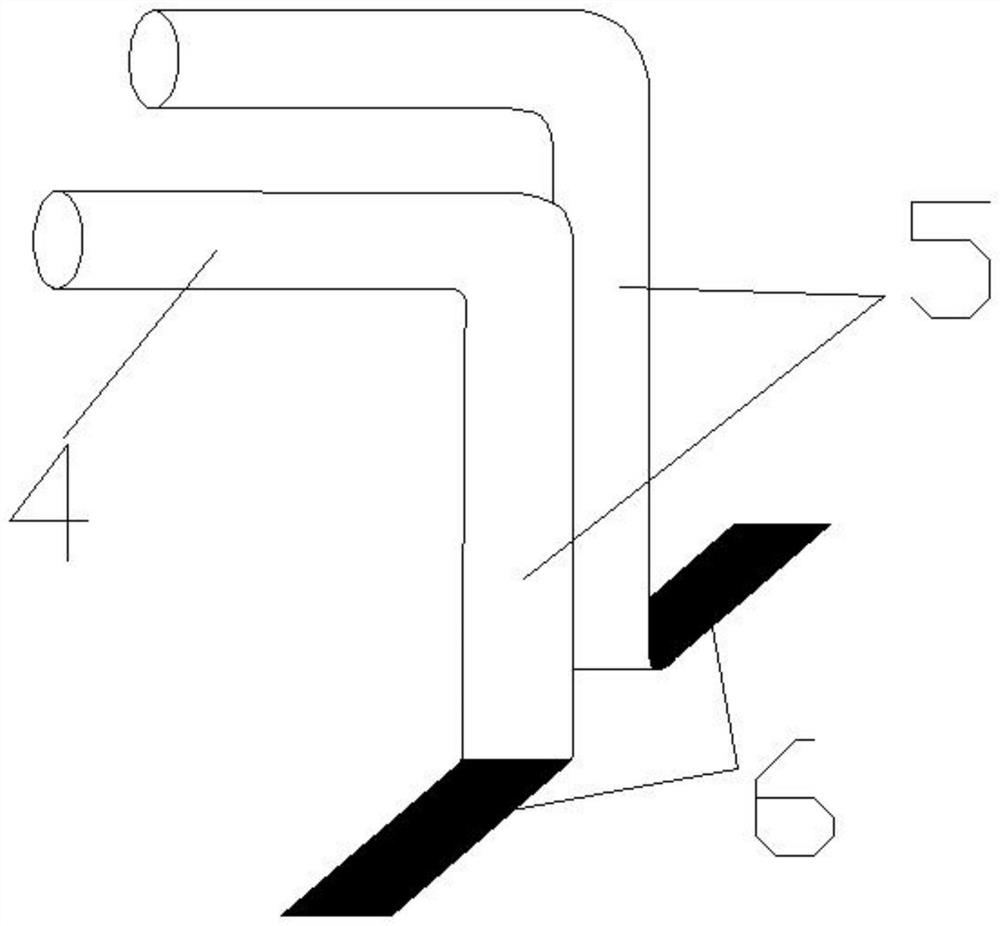

[0044] Example: see Figure 1-6 shown,

[0045]A capacitor, comprising a capacitor body 1, a first pin 2 and a second pin 3 protruding from the right end face of the capacitor body 1, the first pin 2 and the second pin 3 both including the same protection pin 4, heat dissipation Pin 5 and welding pin 6, the length of the heat dissipation pin 5 is greater than the radius of the capacitor body 1, the upper surface of the welding pin 6 is provided with a number of evenly distributed through holes 7, the shape of the through hole 7 is a quadrangular truncated A circular channel 8 extends obliquely upward at 30 degrees from the four sides of the table, and the through hole 7 and the circular channel 8 are filled with solder, and the heat dissipation pin 5 can make the capacitor body 1 and the circuit board after welding. With a certain gap, the air can normally circulate around the capacitor body 1, so that the heat dissipation is faster, and the high temperature generated by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com