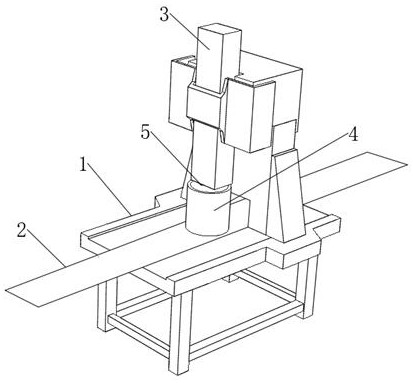

Bulging test equipment for aluminum electrolytic capacitor

A technology of aluminum electrolytic capacitors and testing equipment, which is applied in the direction of instruments, measuring electronics, measuring devices, etc., can solve problems that affect the use of capacitors, hidden safety hazards, etc., and achieve the effect of improving the safety of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

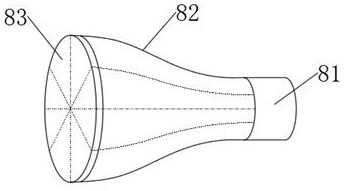

[0027] See Figure 4-5 , Acknowledging the original column 61, the duggling end block 62 and the marking rod 63, the jacket pillar 61 away from the liquid injection cylinder 7 to open a tag tank. The marking rod 63 is inserted in the strip tag and is fixed between the clock 62. When the magnetic field of the Magnetic Cover 8 can be enhanced, it will exclude the exclusion of the Magnetic Clocks 62 and push the marking rod 63 to approach the approach to approaching the approach to approaching the markings. The direction of the capacitor moves, and then the tagging of the drum bag area.

[0028] See Figure 6-7 , Tag 63 include multiple -in -one connections. The marking unit includes the insulation layer 631, the mark layer 632, and the multiple traction wire 633, the marking layer 632 is fixed to the one end of the insulation layer 631 away from the duggle ends 62. The insulation layer 631 inlaid is connected to the inside of the indicator layer 632, and a fixed connection between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com