Bonding method for vehicle parts

A technology for parts and vehicles, applied in the direction of bonding methods, surface pretreatment bonding methods, adhesives, etc., can solve problems affecting production beats, etc., and achieve good application prospects, high production efficiency and quality stability, and versatility strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

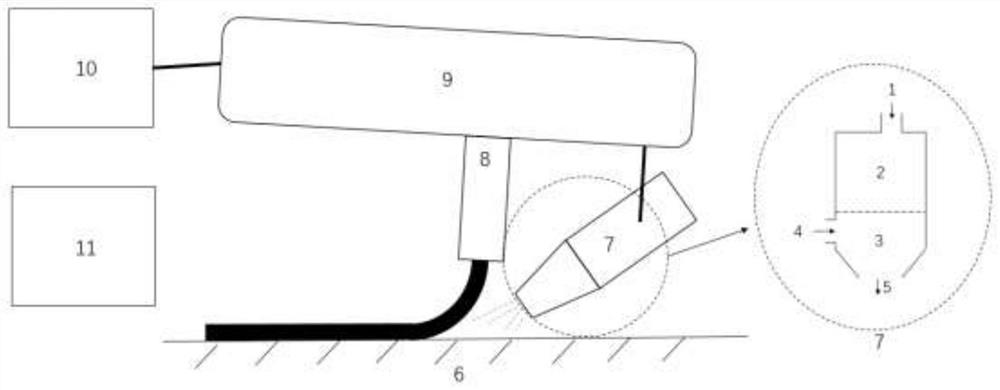

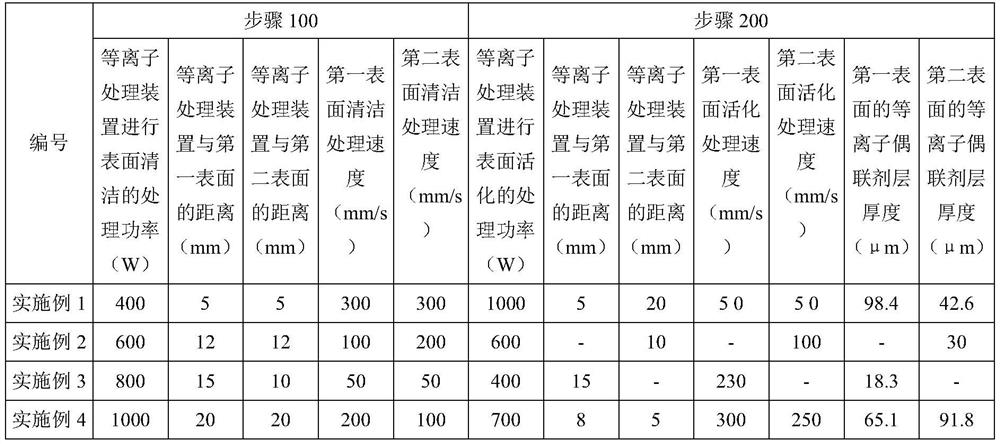

[0035] In the present invention, the inventor enumerates 4 specific embodiments, based on figure 1 For the industrial robot shown, the bonding method implemented in Embodiments 1-4 specifically includes the following steps 100-300:

[0036] 100: Use the plasma treatment device 7 to spray plasma respectively on the first surface and / or the second surface to be bonded to each other for surface cleaning. The processing power of the plasma processing device 7 for surface cleaning is 400-1000W, the distance from the first surface and the second surface is 5mm-20mm, and the surface cleaning processing speed is 50mm / s-300mm / s.

[0037] 200: Using the plasma treatment device 7 to spray a plasma coupling agent on the first surface and / or the second surface for surface activation, so as to form a plasma coupling agent with a thickness of 5-100 μm on the first surface and / or the second surface respectively layer; while the surface is activated, the first surface and / or the second surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap