Method for preparing foamed ceramic by taking navajoite tailings as main material

A technology of vanadium ore tailings and foamed ceramics, which is applied in the direction of ceramic products, ceramic material production, clay products, etc., can solve the problems of lack of treatment and utilization technology, negative effects of industrial sustainable development, etc., to increase the amount of mixing, realize The effect of making full use of and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] like figure 1 As shown, this embodiment includes the following steps:

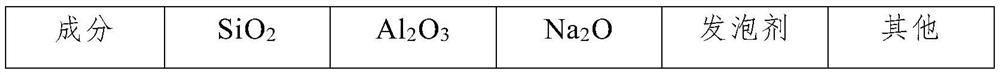

[0033] Step 1: Mixing ratio design: carry out chemical composition detection on vanadium ore tailings, and then calculate the required raw material, main material, vanadium ore tailings and auxiliary material conditioning agents, including conditioning agent 1 and conditioning agent 2, according to the composition of the target product foamed ceramics. , and the quality of the blowing agent;

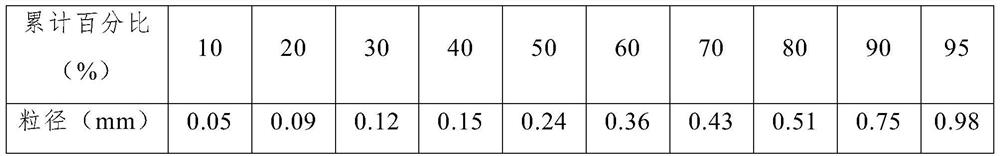

[0034] Step 2, raw material pretreatment: the vanadium ore tailings are crushed by a pair of roller crushers, and then passed through a 100-mesh vibrating screen to obtain the coarse material 1 on the screen and the fine material 1 on the screen;

[0035] Described vanadium ore tailings are the tailings after the extraction of vanadium ore in Shangluo Shanyang County, Shaanxi Province, and the mass content of water in the vanadium ore tailings is 2%, the mass content of silicon dioxide is 79.13%, and the spec...

Embodiment 2

[0052] like figure 1 As shown, this embodiment includes the following steps:

[0053] Step 1: Mixing ratio design: carry out chemical composition detection on vanadium ore tailings, and then calculate the required raw material, main material, vanadium ore tailings and auxiliary material conditioning agents, including conditioning agent 1 and conditioning agent 2, according to the composition of the target product foamed ceramics. , and the quality of the blowing agent;

[0054] Step 2, raw material pretreatment: the vanadium ore tailings are crushed by a pair of roller crushers, and then passed through a 100-mesh vibrating screen to obtain the coarse material 1 on the screen and the fine material 1 on the screen;

[0055] Described vanadium ore tailings are the tailings after the vanadium ore extraction in Shangluoshan Yang County, Shaanxi Province, and the mass content of water in the vanadium ore tailings is 3%, the mass content of silicon dioxide is 75.16%, and the specifi...

Embodiment 3

[0071] like figure 1 As shown, this embodiment includes the following steps:

[0072] Step 1. Mixing ratio design: carry out chemical composition detection on vanadium ore tailings, and then calculate the required raw material, main material, vanadium ore tailings and auxiliary material conditioning agents, including conditioning agent 1 and conditioning agent 2, according to the composition of the target product foamed ceramics. , and the quality of the blowing agent;

[0073]Step 2, raw material pretreatment: the vanadium ore tailings are crushed by a pair of roller crushers, and then passed through a 100-mesh vibrating screen to obtain the coarse material 1 on the screen and the fine material 1 on the screen;

[0074] Described vanadium ore tailings are tailings after the extraction of vanadium ore in Shangluo Shanyang County, Shaanxi Province, and the mass content of water in the vanadium ore tailings is 1%, the mass content of silicon dioxide is 84.23%, and the specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com