Floating type wind power foundation with steel-concrete mixed structure

A hybrid structure and concrete technology, which is applied in wind power generation, floating buildings, ships, etc., can solve the problems of steel structure material price changes, different production capabilities, and cost differences, and achieve low cost, strong market competitiveness, and The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

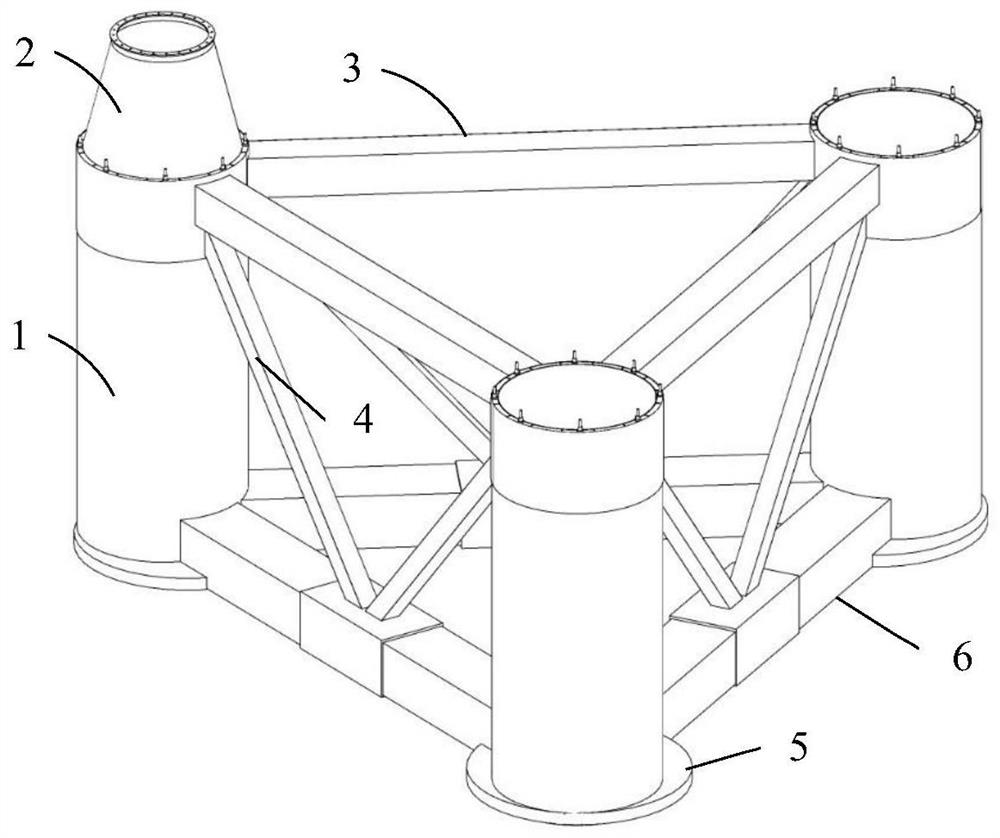

[0030] like figure 1 As shown, the present invention is a steel-concrete hybrid structure floating type wind power foundation system, the buoy (1) is vertically connected with the heave plate (5), the buoys (1) are connected by a horizontal bracing steel pipe (3), and the vertical The horizontal coupling beams (6) are used to connect the swing plates (5), and the buoys (1) and the horizontal coupling beams (6) are connected in a V-shape by using diagonal bracing steel pipes (4). Internal round steel tube welded.

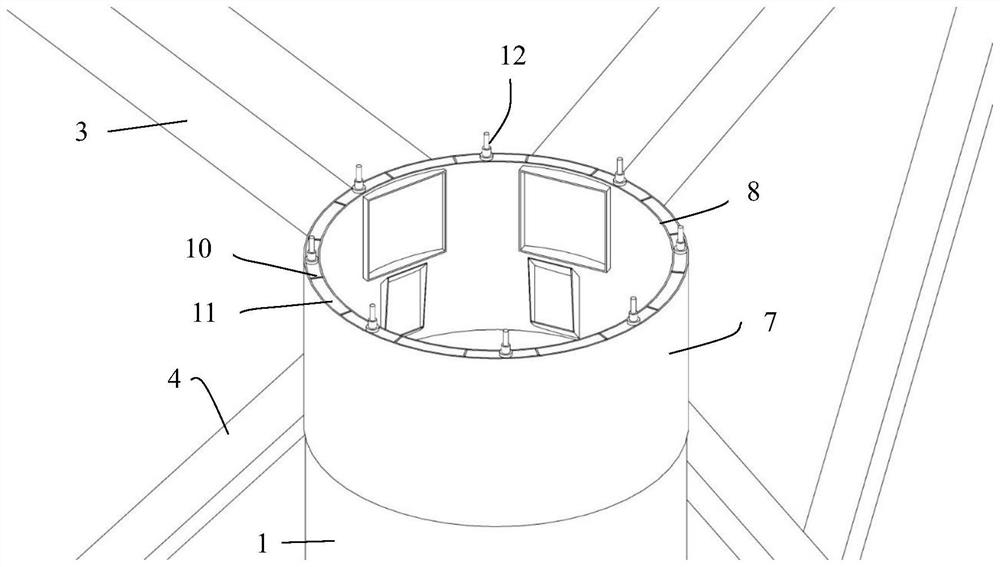

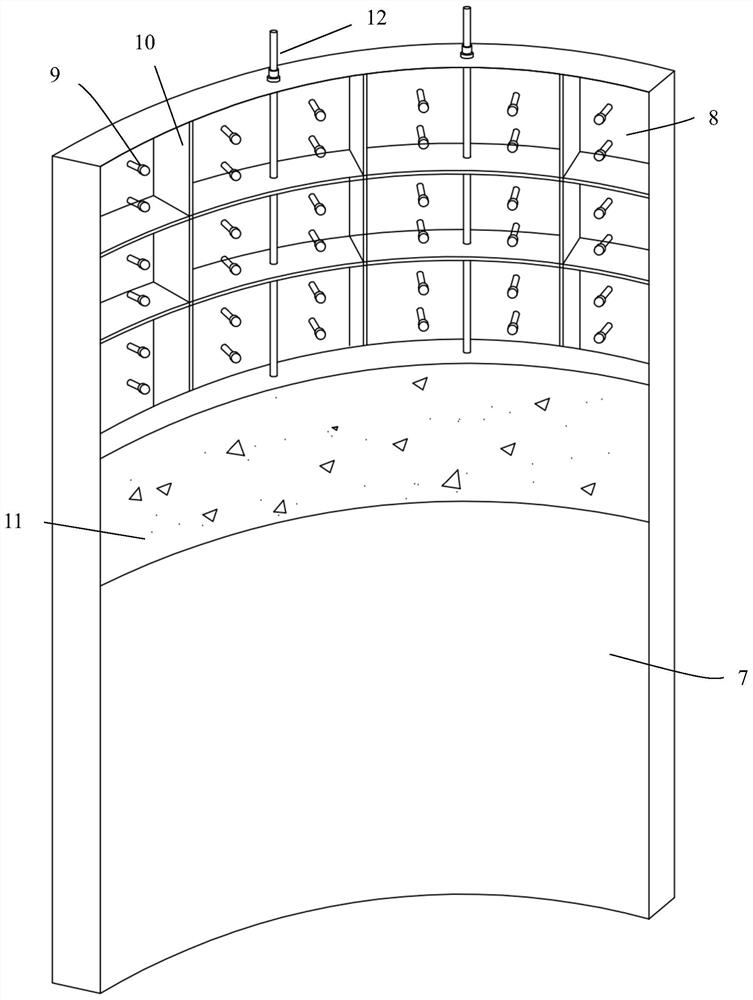

[0031] like image 3 As shown in the figure, the anchoring area above the buoy (1) is connected with the transverse bracing steel pipe (3) and the diagonal bracing steel pipe (4), and the circular outer steel pipe (7) and the circular inner steel pipe (8) are used to wrap the concrete (11), and the Double-layer steel pipes are connected using stiffening pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com