Asphalt crushing equipment and crushing method thereof

A technology of crushing equipment and asphalt, which is applied in the direction of mechanical material recovery, grain processing, recycling technology, etc., can solve the problems of no screening treatment, slow efficiency, low efficiency, etc., to prevent clogging, high efficiency, and improve crushing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

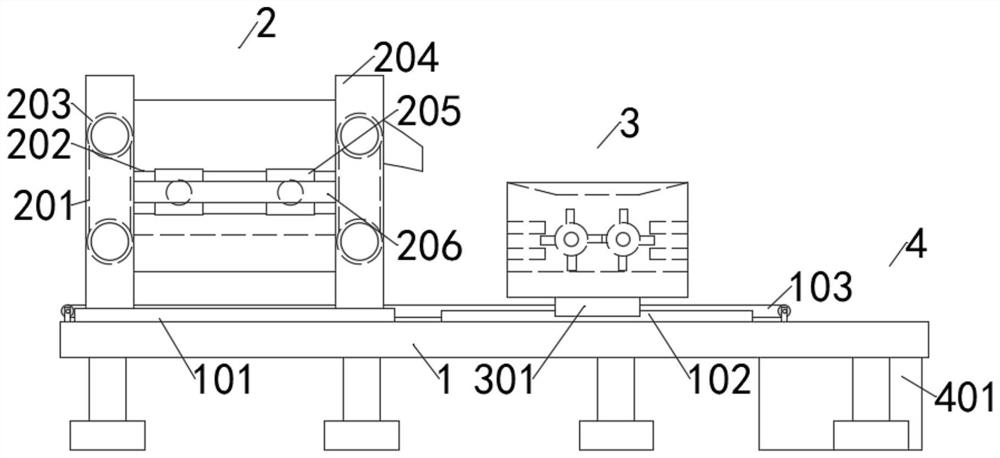

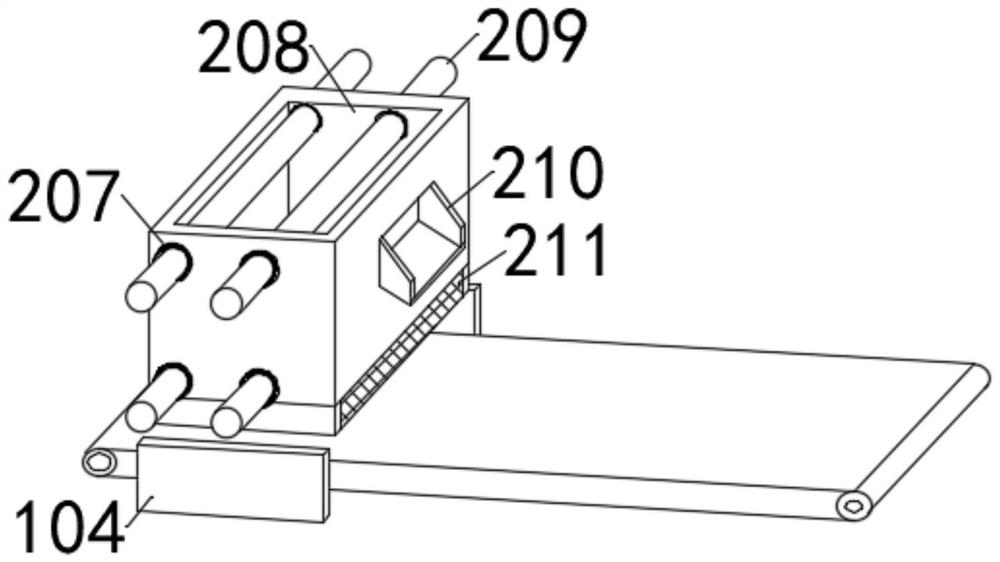

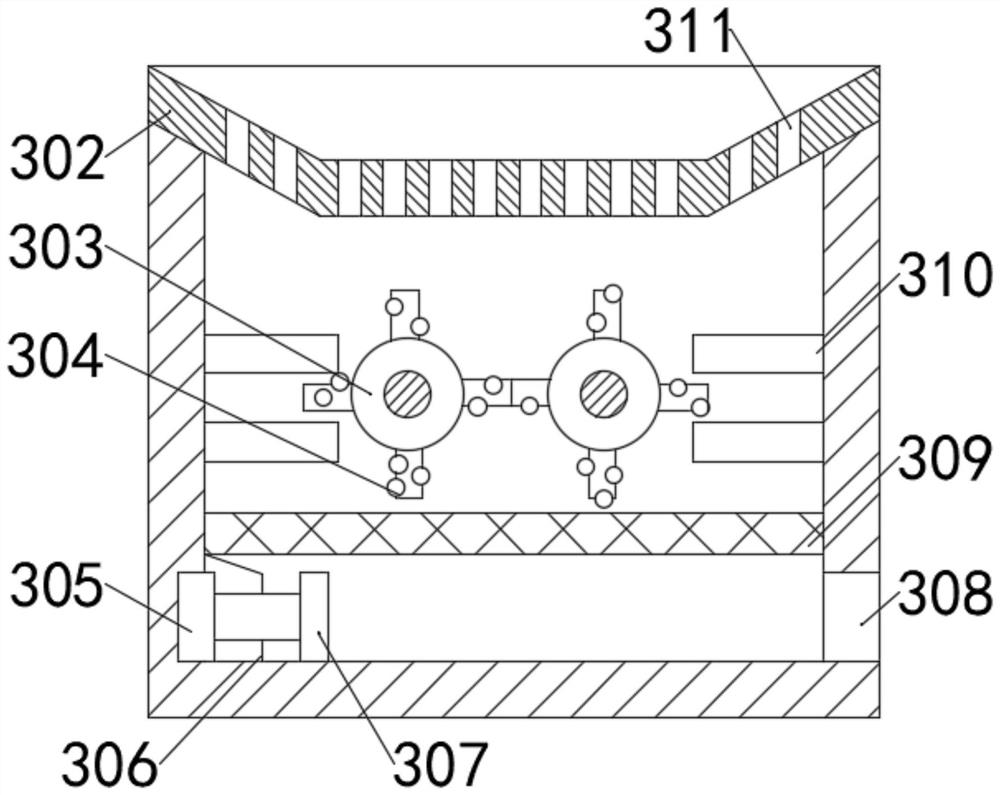

[0031] like Figure 1-Figure 4 As shown, an asphalt crushing equipment is installed on the frame 1 with a conveyor belt 103. The conveyor belt 103 transports the tiny asphalt in the vibrating screen section 2 and the asphalt crushed by the crusher to the waste residue storage tank 401. The conveyor belt 103 is provided with a vibrating table 101 and a slide rail 102 on both sides, and the stand 204 is symmetrically mounted on the vibrating table 101. An electric slide 301 is slidably connected to the slide rail 102, and the crusher is installed on the electric slide 301. The electric slide 301 operates the crusher to the outlet plate 210, and the highest point of the crusher reaches the table 1 of the rack. The distance is less than the distance from the lowest point of the outlet plate 210 to the table top of the rack 1, which is convenient for collecting the large-particle asphalt screened out by the vibrating screen partition 2. There is also a collection area 4 on one side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com