Display panel and display panel manufacturing method

A technology for a display panel and a manufacturing method, which is applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as cross-coloring, and achieve the effects of low cost, good display effect, and improved product brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

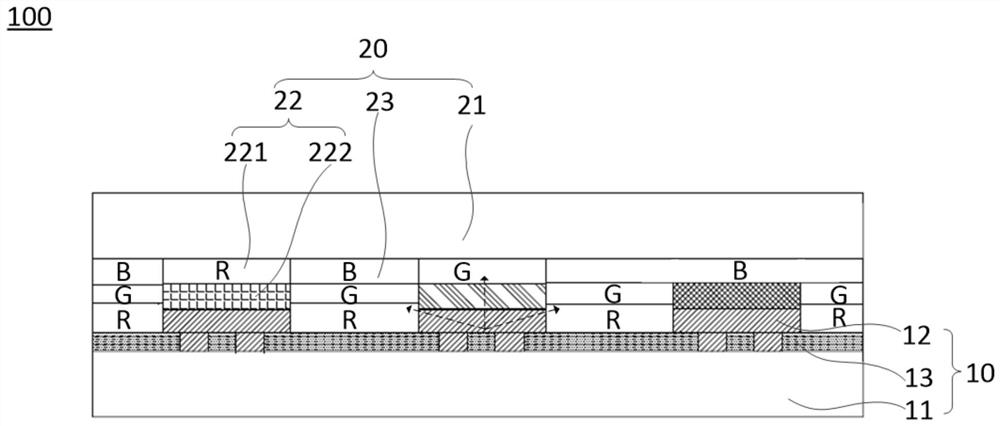

[0046] Embodiment 1 of the first aspect of the present application proposes a display panel. Please refer to figure 1 , the display panel 100 includes an array substrate 10 and a color filter substrate 20 disposed opposite to each other.

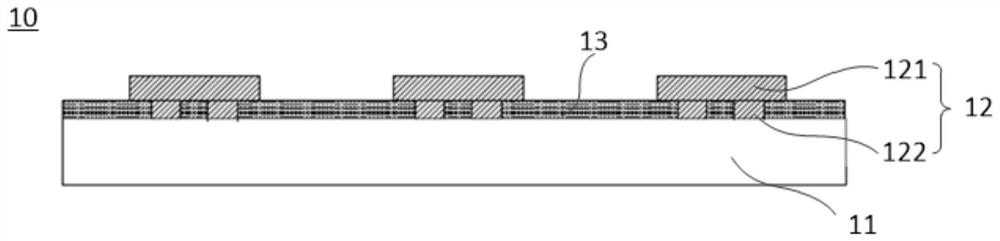

[0047]The array substrate 10 includes a first substrate 11 and a plurality of micro LEDs 12 , and the plurality of micro LEDs 12 are arrayed on the first substrate 11 at intervals. The micro-LED 12 refers to a micro-LED with a chip size between 0.5-200 microns. The micro-LED 12 can be a micro LED with a chip size between 0.5-100 microns, or a chip with a chip size between 50-200 microns. between miniLEDs. In this embodiment, the micro LED 12 is described as a micro LED.

[0048] A driving circuit (not shown) is also provided on the first substrate 11, and the driving circuit may include several scanning lines, several signal lines, and thin film transistors (Thin Film Transistor, TFT) arranged in an array, wherein the multiple scanning li...

Embodiment 2

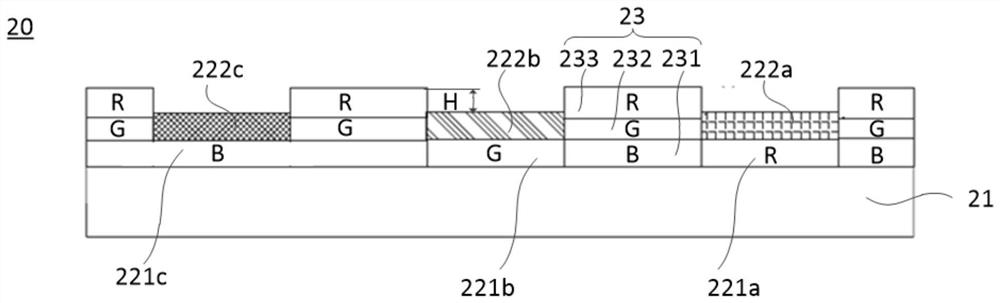

[0068] The display panel provided in the second embodiment is similar to that in the first embodiment, including a first substrate 11 and a second substrate 21 oppositely arranged, micro LEDs 12 arrayed on the first substrate 11, and a color conversion panel arranged on the second substrate 21 The light-shielding element 23 includes a first color-resist layer 231 , a second color-resist layer 232 and a third color-resist layer 233 stacked on the second substrate 21 in sequence.

[0069] Please refer to Figure 4 , Figure 4 It schematically shows the color filter substrate 20 in the display panel provided by the second embodiment, wherein the first color-resist layer 231 in the light-shielding member 23 is a blue color-resist layer, the second color-resist layer 232 is a red color-resist layer, and the third color-resist layer The resist layer 233 is a green color resist layer, that is, the stacking sequence of the color resist layers in the light shielding member 23 is B-R-G...

Embodiment 3

[0072] The display panel provided in the second embodiment is similar to that in the first embodiment, including a first substrate 11 and a second substrate 21 oppositely arranged, micro LEDs 12 arrayed on the first substrate 11, and a color conversion panel arranged on the second substrate 21 Device 22 and shade 23.

[0073] Please refer to Figure 5 , Figure 5 The color filter substrate 20 in the display panel provided by the third embodiment is schematically shown, wherein the light-shielding member 23 includes a first color-resist layer 231 and a second color-resist layer 232 stacked on the second substrate 21 in sequence, the first color-resistor Layer 231 is a blue color-resist layer, and the second color-resist layer 232 is a red color-resist layer.

[0074] In this embodiment, the shading member 23 includes both a blue color-resisting layer and a red color-resisting layer, so that the shading member 23 can play a role of shading light; and, the blue light emitted by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com