Miniature high-precision electro-hydraulic proportional synchronizing system capable of adjusting contraction-expansion nozzle actuating ring

An electro-hydraulic proportional and synchronous system technology, applied in fluid pressure actuation system components, fluid pressure actuation system testing, sustainable transportation, etc. High synchronization control accuracy, high modular integration, stable and reliable performance

Pending Publication Date: 2022-05-31

陈田

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The use of electric actuators to control the retraction and expansion of the tail nozzle usually has the following problems: 1) The adaptability is not strong, the power output of the electric drive system is limited, the power quality is relatively small, and the advantage of wide-range afterburner demand is insufficient; the turbojet engine unit The increase in mass will be magnified by 7 to 8 times on the aircraft, and the system must have a higher power-to-mass ratio; 2) The control accuracy is not high. The control difficulty brought about by the deformation of the dynamic structure increases, and the structure of the equipment itself and the performance of the electric drive are also easily affected; 3) The cost is high, and a special miniature high-precision electric drive system for the aerospace field is required, which is expensive and difficult to develop independently , does not meet the economic requirements of the product

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

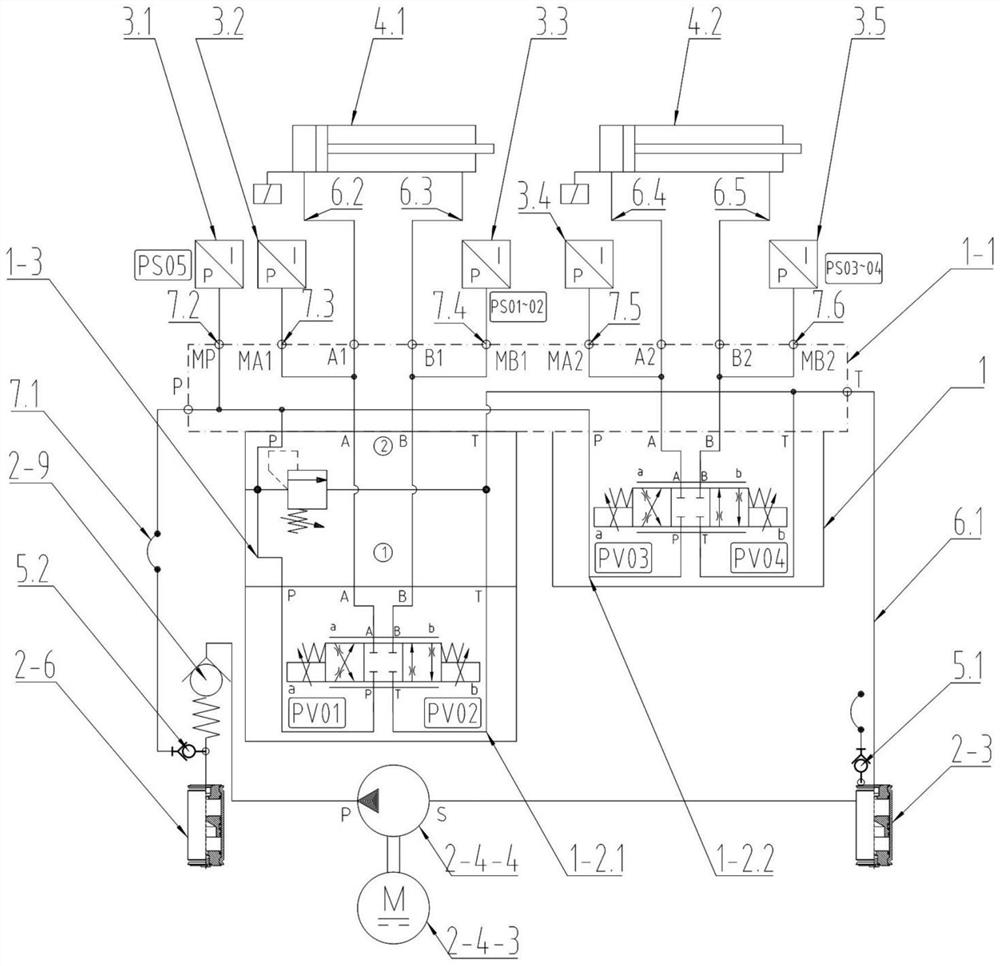

[0060] In the present invention, the control for the servo oil cylinder 4 is shown in FIG. 8 . Each servo cylinder 4 has its own proportional reversing valve

[0066] The foregoing descriptions of specific exemplary embodiments of the present invention have been presented for purposes of illustration and description. these descriptions

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

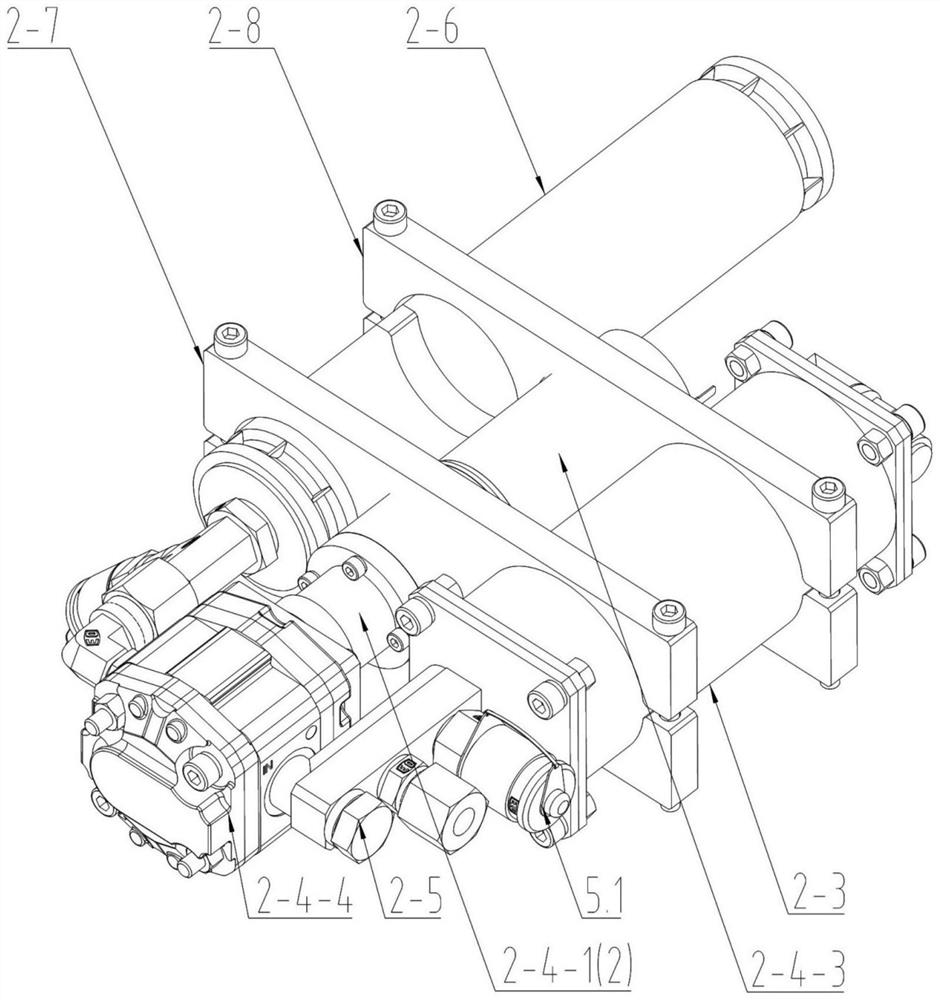

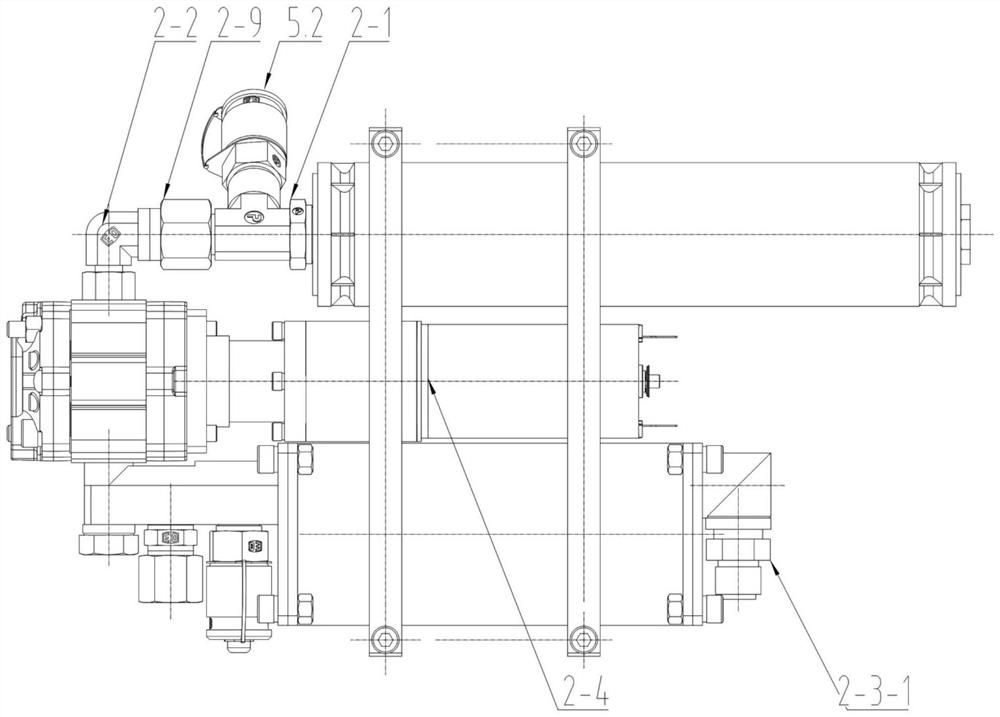

The invention discloses a miniature high-precision electro-hydraulic proportional synchronizing system capable of adjusting a contraction-expansion nozzle actuating ring, which mainly controls the precise synchronous movement of the nozzle actuating ring through a special electro-hydraulic proportional system on the basis of the existing structure and limited space, and simultaneously considers the wide temperature adaptability, light weight and economical efficiency of equipment. And the force adding / receiving index required by the aircraft is met, so that the aircraft has good maneuvering characteristics. By utilizing the advantages of hydraulic transmission in the aspects of high-power mass ratio, action stability, automatic control, stepless speed regulation and the like, the electro-hydraulic proportional synchronous system meets the stress application requirement of 600kg-level axial thrust vector of a certain small turbojet engine through cooperative regulation and control of contraction and expansion of a spray pipe.

Description

A miniature high-precision electro-hydraulic proportional synchronization system for an adjustable retractable-spreading pipe actuating ring Technical field: The invention belongs to the technical field of turbojet engine control, and in particular relates to an adjustable retractable-spreading pipe actuating ring miniature A high-precision electro-hydraulic proportional synchronization system and a system preprocessing method thereof. Background technology: Today's battlefield form of great power wrestling puts forward higher-level requirements for intelligent combat technology. China's mechanized cluster assault, using the air to control the ground, and capturing the three-dimensional advantage of the air and the ground, this operational strategy focuses on highlighting the compatibility with it. combat effectiveness. As a basic key unit, high mobility air combat equipment has irreplaceable development advantages. for Some auxiliary combat training equipment such...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F15B9/17F15B9/09F15B21/08F15B21/02F15B13/02F15B19/00

CPCF15B9/17F15B9/09F15B21/08F15B21/02F15B13/02F15B19/00Y02T50/60

Inventor 陈田

Owner 陈田

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com