Large-dose liquid filling and sealing machine

A filling and sealing machine, high-dose technology, applied in liquid treatment, liquid bottling, bottle filling, etc., can solve the problems of filling bottle impact, filling head cannot flexibly control injection volume, and cannot meet actual use needs, etc. Achieve the effect of solving severe impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

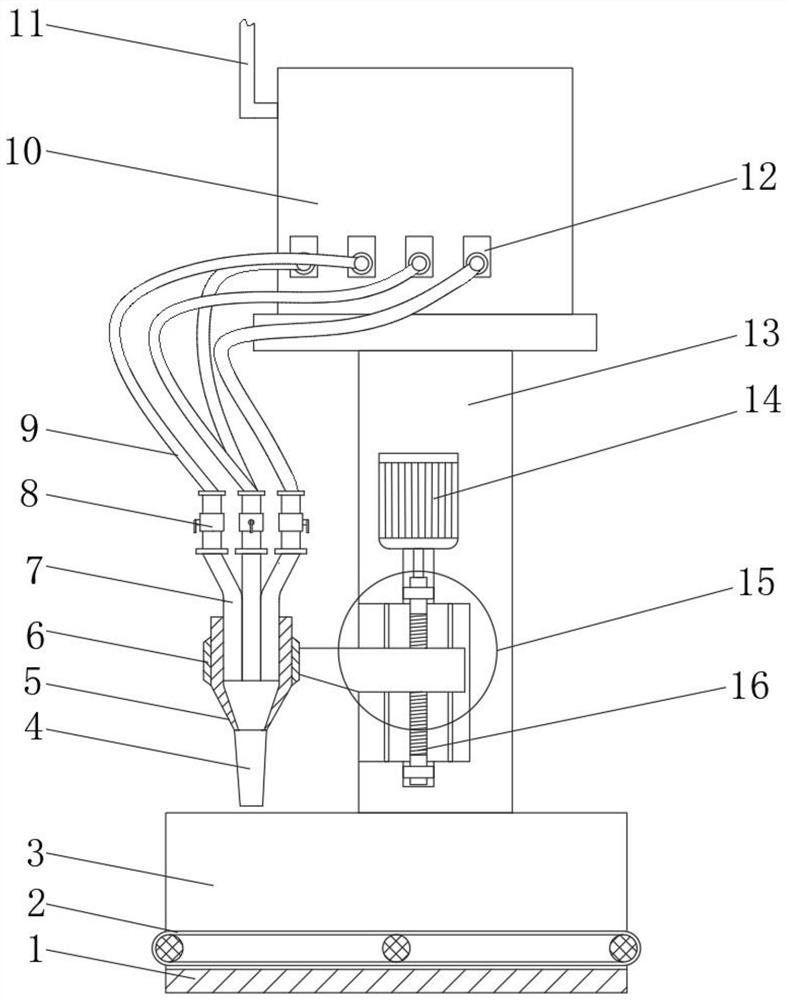

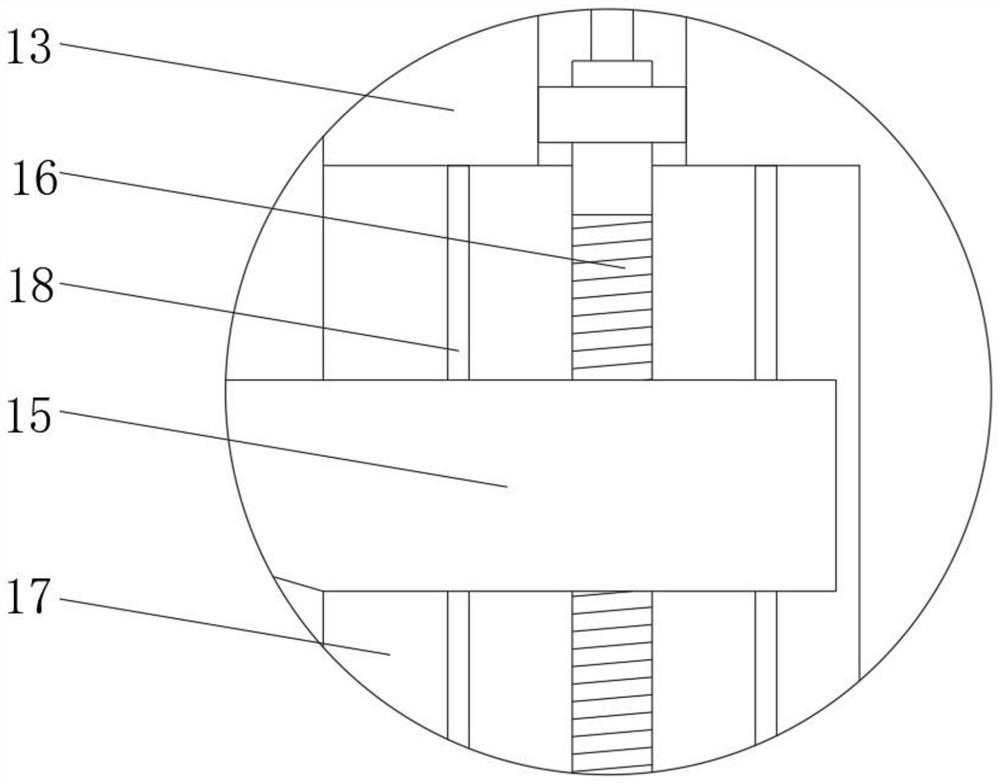

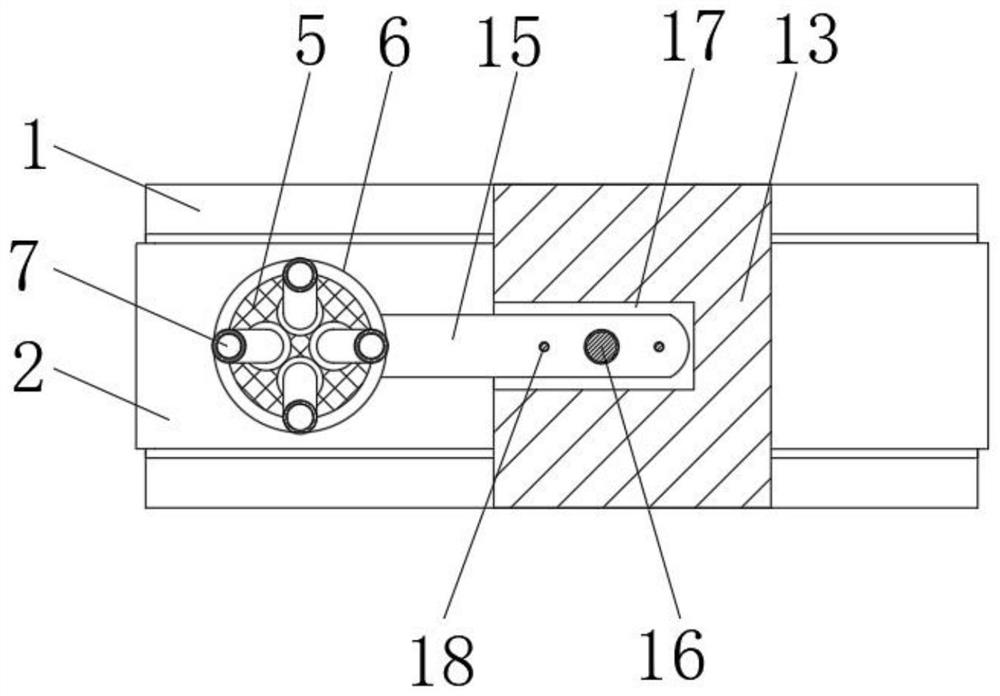

[0021] Such as Figure 1-3 As shown, a kind of large-dose liquid filling and sealing machine that the present invention proposes comprises frame 1, shunt pipe 7 and support frame 13, and the top of frame 1 is provided with conveyer belt 2, can facilitate filling bottle to be moved to by conveyer belt 2 Just below the filling head 5, the device can transport the filling bottle, avoiding the staff to manually place the filling bottle under the filling head 5, which effectively reduces the labor intensity of the staff. The symmetrical welding on the frame 1 has Side plate 3, the upper surface of side plate 3 is welded with support frame 13, and support frame 13 is provided with chute 17 on one side different from the upper and lower ends, and the inside of chute 17 is provided with screw mandrel 16, and the outer wall of screw mandrel 16 is threadedly connected There is a slider 15, and the inside of the support frame 13 is provided with a servo motor 14. Of course, as is well kn...

Embodiment 2

[0024] Such as Figure 1-3 As shown, a large-dose liquid filling and sealing machine proposed by the present invention, compared with Embodiment 1, this embodiment also includes: a discharge chute 10 is installed on the upper end of the support frame 13, and one side of the discharge chute 10 is equidistant A delivery pump 12 is provided. Of course, as is well known to those skilled in the art, the provision of the delivery pump 12 is commonplace, which all belong to conventional means or common knowledge, and will not be described in detail here. Those skilled in the art can according to their needs or convenience Optional matching is carried out, and the upper end of the connecting hose 9 is connected to the delivery pump 12, and the outer wall of the discharge tank 10 is connected with the feeding pipe 11 on the side wall different from the upper and lower ends, through the feeding pipe 11, it is convenient for the staff. Adding it into the feeding chute 10 effectively redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com