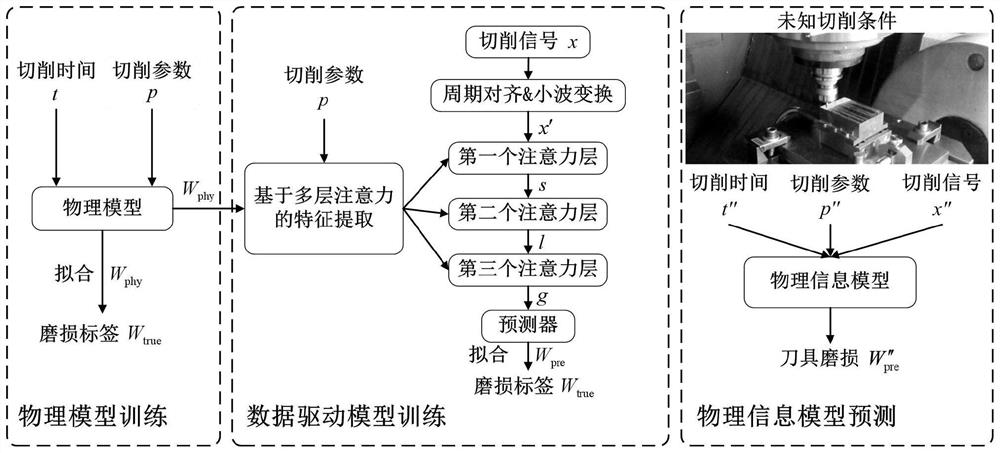

Cutter wear monitoring method based on physical information fusion

A technology of tool wear and physical information, applied in manufacturing tools, measuring/indicating equipment, metal processing equipment, etc., to achieve the effect of reducing economic losses, low prediction errors, and reducing model complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

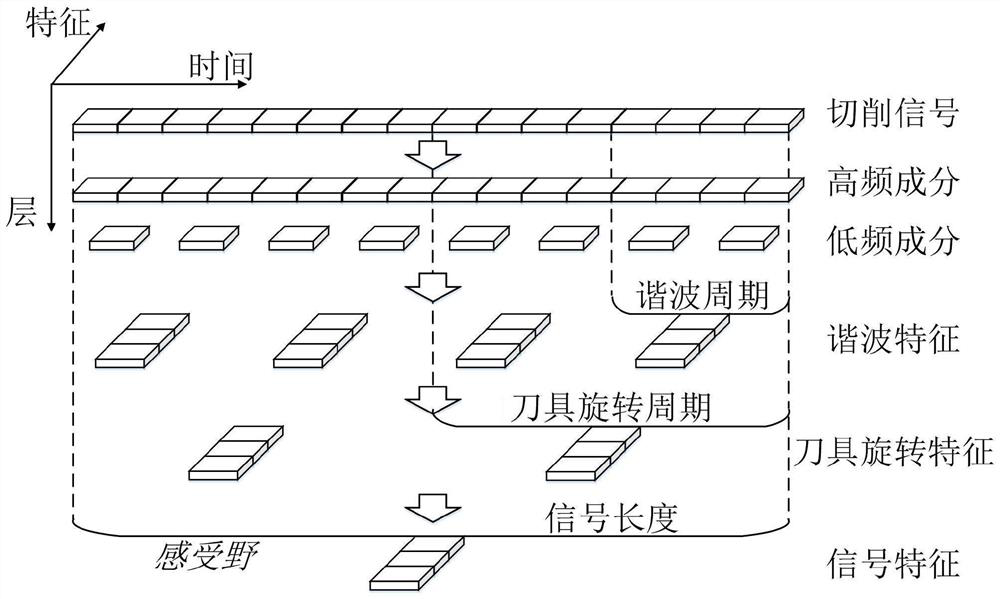

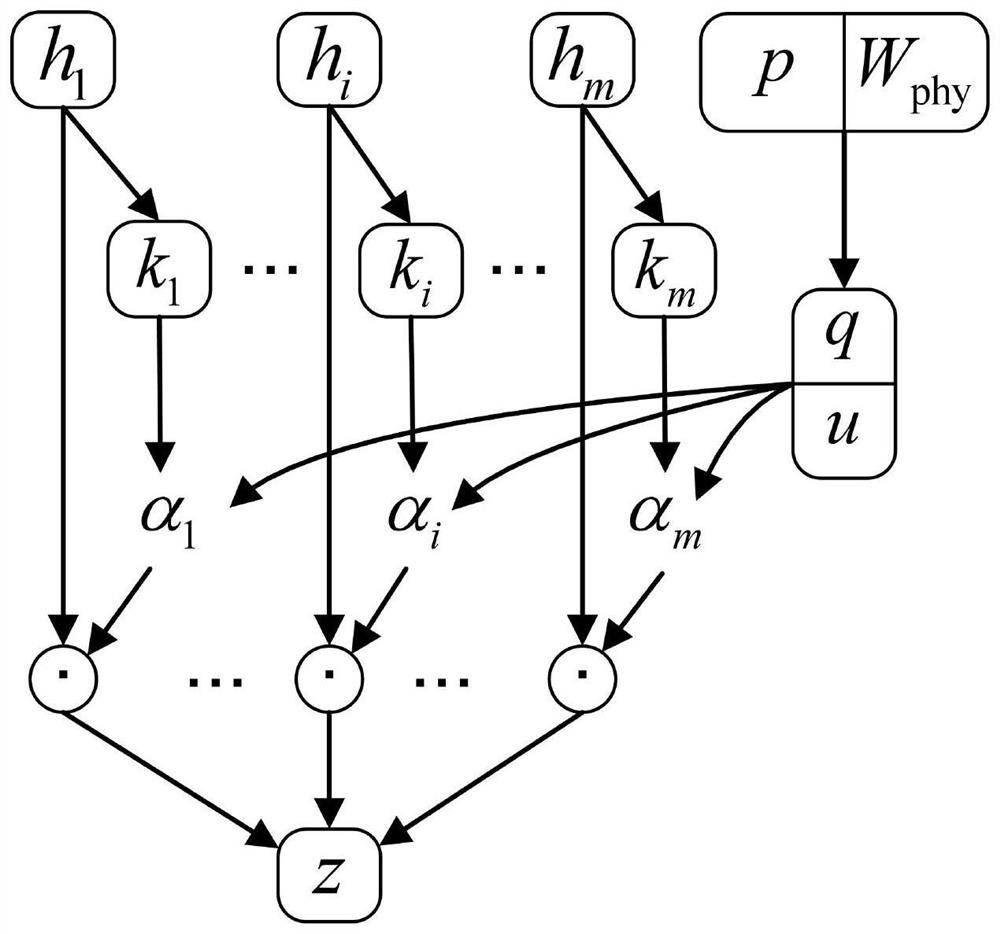

Method used

Image

Examples

Embodiment Construction

[0036] In this embodiment, a tool wear monitoring method based on physical information fusion combines a physical model and a data-driven model to realize real-time high-precision tool wear monitoring, including: CNC machine tools, force sensors, industrial computers, and physical information algorithms:

[0037] In this embodiment, the CNC machine tool adopts the high-speed milling machining center Mikron HSM600U, which includes a bus interface and a sensor bracket, the force sensor is installed on the sensor bracket, and the milling cutters used are all three-blade milling cutters. The workpiece adopts AISI4340 square die. The workpiece was rough-milled before the experiment to ensure the flatness of the workpiece. The workpiece surface is cut in a zigzag shape by the tool from the upper edge to the lower edge. After each transverse cut, the wear of both edges was measured by a LEICAMZ12 microscope. During the processing of the workpiece, the cutting force signal is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com