Weighing interlocking automatic casting system and casting method

A casting system and automatic technology, applied in the direction of casting molds, casting mold components, casting equipment, etc., can solve the problems of non-quantitative casting, unreliable guarantee of personnel safety, high labor intensity of personnel, etc., and achieve convenient on-site process and safe operation, improve processing efficiency and safety, and ensure the effect of process production safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

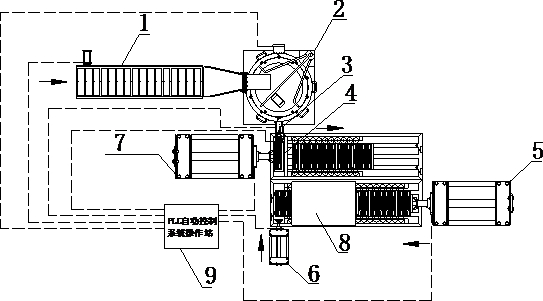

[0043] see Figure 1~7 , the present invention provides a weighing chain automatic casting system, the weighing chain automatic casting system includes a furnace feeding device, a furnace casting device, a mold assembly 19, a mold preheating device and a PLC control system 9;

[0044] The furnace feeding device is used to transport metal materials to the furnace casting device. In this embodiment, the furnace feeding device is a plate chain conveyor 1;

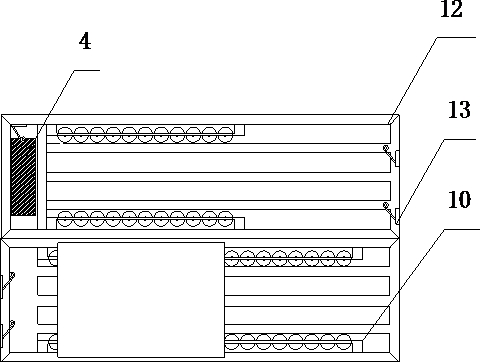

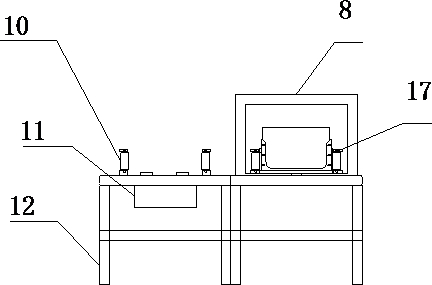

[0045] The mold preheating device is used to preheat the mold assembly to be cast. In this embodiment, the mold preheating device is set as a mold oven 8;

[0046] The melting furnace casting device includes a melting furnace 2, a weighing assembly and a conveying assembly; the melting furnace 2 is used for melting metal materials and casting molten metal into a mold assembly 19 located on a weighing platform 4; in this embodiment Among them, the melting material furnace 2 includes a furnace body and a first heating assembly ...

Embodiment 2

[0052] This embodiment provides a casting method, which uses the weighing chain automatic casting system in Embodiment 1, and specifically includes the following steps:

[0053] (1) Under the control of the PLC control system 9, the plate chain conveyor 1 automatically lifts the metal ingot to the feeding port of the melting furnace 2, and the metal ingot is automatically melted after the melting temperature is set and the metal ingot falls into the melting furnace 2;

[0054] (2) After the graphite mold 14 and the mold moving bracket 17 are combined and installed, put them into the placement area of the steel frame track platform 12. After placing them, control the first hydraulic propulsion device 5 to move the mold assembly through the PLC control system 9 19 Push into the mold oven 8 for preheating, after the preheating is completed, an automatic alarm prompts for the next step;

[0055] (3) After the mold assembly 19 is preheated, the PLC control system 9 controls the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com