Mixing process for doping aluminum oxide with activated carbon

A mixing process and activated carbon technology, which is applied to mixers with rotating stirring devices, mixers, and other chemical processes, can solve problems such as easy blockage of pores, uneven mixing, and stratification, and achieve high use efficiency and solution strength low effect

Pending Publication Date: 2022-05-31

山西炬华新材料科技有限公司

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the microporous structure of activated carbon is single, the pore size is small, and the pores are easily blocked, which limits the adsorption performance of activated carbon for large-volume molecules.

In order to improve the adsorption effect on large-volume molecules, people try to mix activated carbon with alumina to obtain composite materials. However, after the conventional mixture is mixed and left for a period of time, there will be stratification and other phenomena, resulting in uneven mixing. To this end, we propose a hybrid process for alumina doped with activated carbon

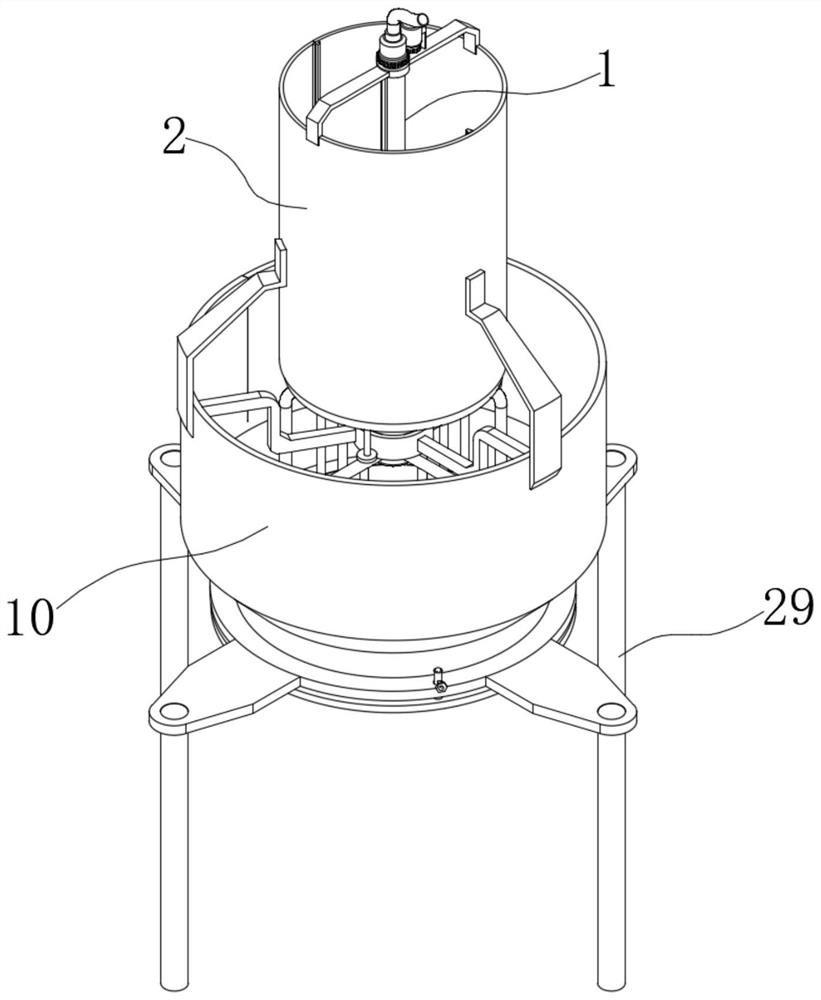

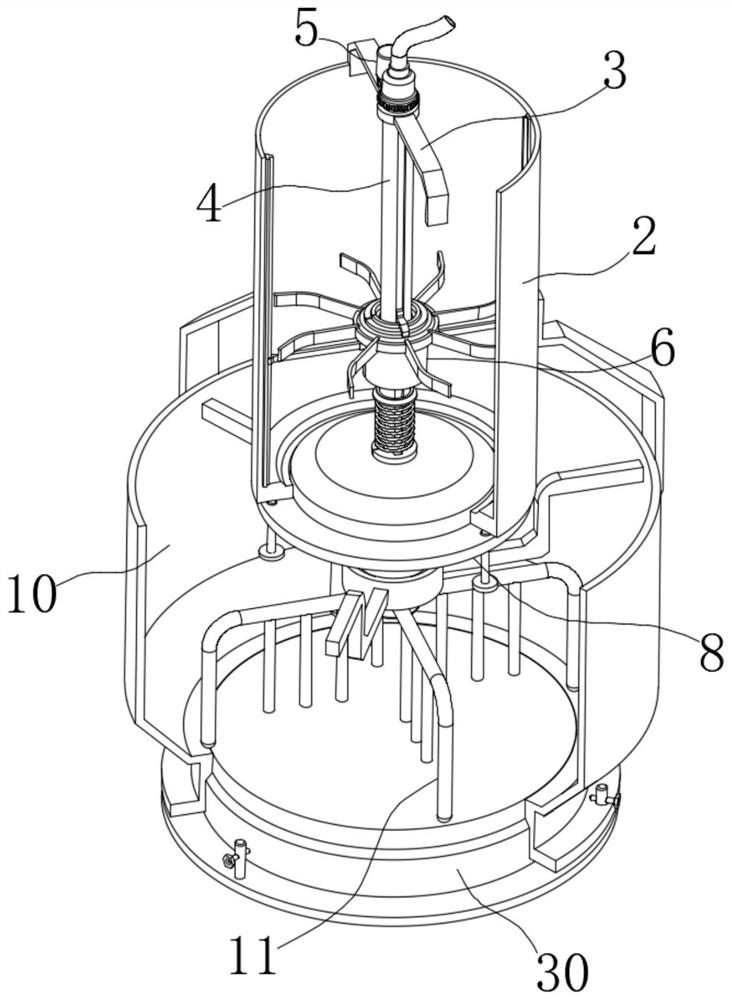

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

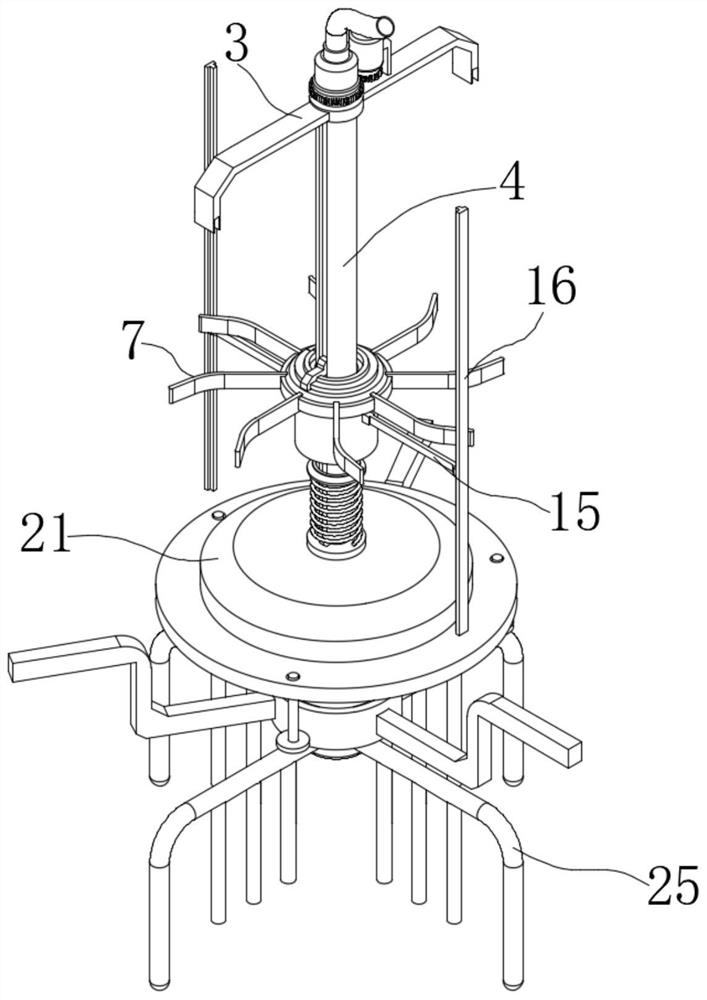

[0050] Meanwhile, please refer to FIG. 3-FIG. 5, the sealing assembly 8 in the illustration includes a sealing plate 21 which is abutted against the bottom end of the storage bucket 2,

Embodiment 2

Embodiment 3

[0063] It should be noted that: through the additional limit rod 28 and the sealing plate 21 sliding plug, so that the sealing plate 21

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a mixing process for doping aluminum oxide with activated carbon, relates to the technical field of microporous materials, and solves the problems that an existing activated carbon material is single in microporous structure, small in pore diameter and easy to block pore channels. Comprising the following raw materials in percentage by mass: 30-70% of aluminum oxide, 30-70% of activated carbon and 15-35% of a binder, the sum of the mass percentages of all the raw material components is 100%, and the aluminum hydroxide and the activated carbon are powder. The activated carbon is firmly and uniformly fixed in the activated aluminum oxide through sintering, perfect combination of the activated carbon and the activated aluminum oxide is achieved, the problems that the activated carbon is low in strength, short in service life and the like are solved, meanwhile, the designed pre-stirring mechanism achieves pre-stirring of raw materials and re-stirring after a binder aqueous solution is mixed, and the use efficiency is higher.

Description

A kind of mixing process for alumina mixed with activated carbon technical field [0001] The present invention relates to the technical field of microporous materials, in particular to a mixing process for alumina-doped activated carbon. Background technique [0002] In the field of environmental engineering, adsorption is widely used in oil and gas recovery. The advantage of the adsorption method is that it operates as Low cost, high purification efficiency, mature technology and wide application range. The key to recovering oil and gas by adsorption is to screen out high-efficiency adsorbents. High-efficiency adsorbents usually have the following characteristics: ① large specific surface area; ② good pore structure characteristics; ③ large adsorption capacity; ④High desorption efficiency; ⑤Easy synthesis and regeneration. The current microporous materials have the advantages of good adsorption performance, high hydrothermal stability, and are therefore widely used i...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J20/20B01J20/30B01F27/87B01F27/191B01F27/213

CPCB01J20/20B01J20/08B01J20/3042B01J20/3007B01J20/3078Y02E60/13

Inventor 郭晓琛郭万里梁雪飞朱小龙卢效勤郭超冰杨凡袁野

Owner 山西炬华新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com