Flow and pressure combined control system and method for multiple cold and reheat supply units

A joint control, flow pressure technology, applied in heating systems, hot water central heating systems, heating methods, etc., can solve problems such as extensive control, no economic evaluation index, and unreal-time balance of steam supply flow, and achieve optimal combination Scheduling, realization of flow demand estimation calculation and real-time adjustment, and the effect of ensuring the quality of steam parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

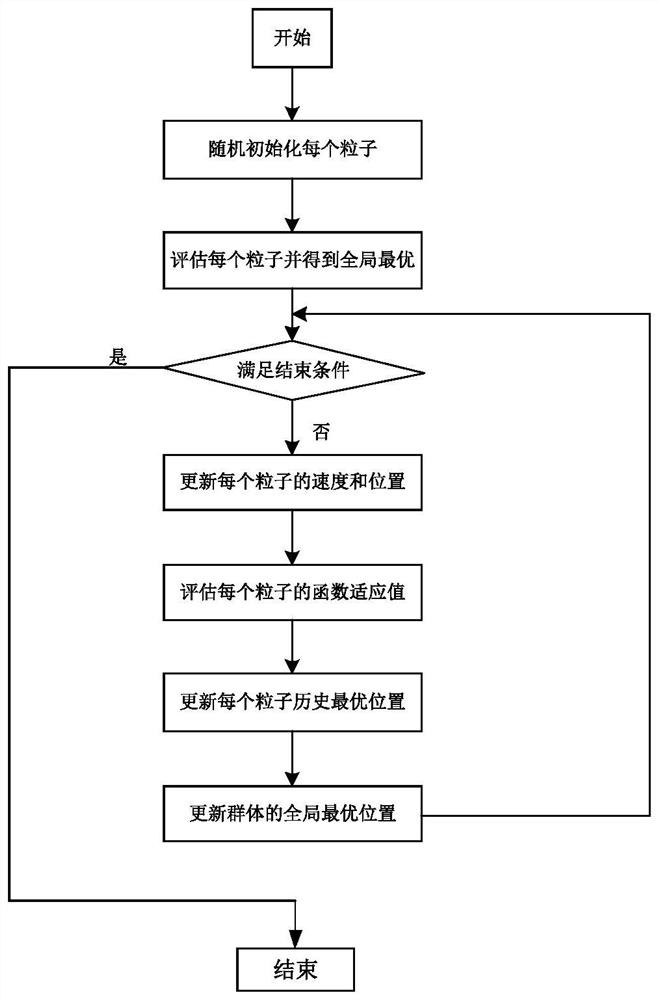

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples are only used to explain the present invention, but not to limit the scope of the present invention.

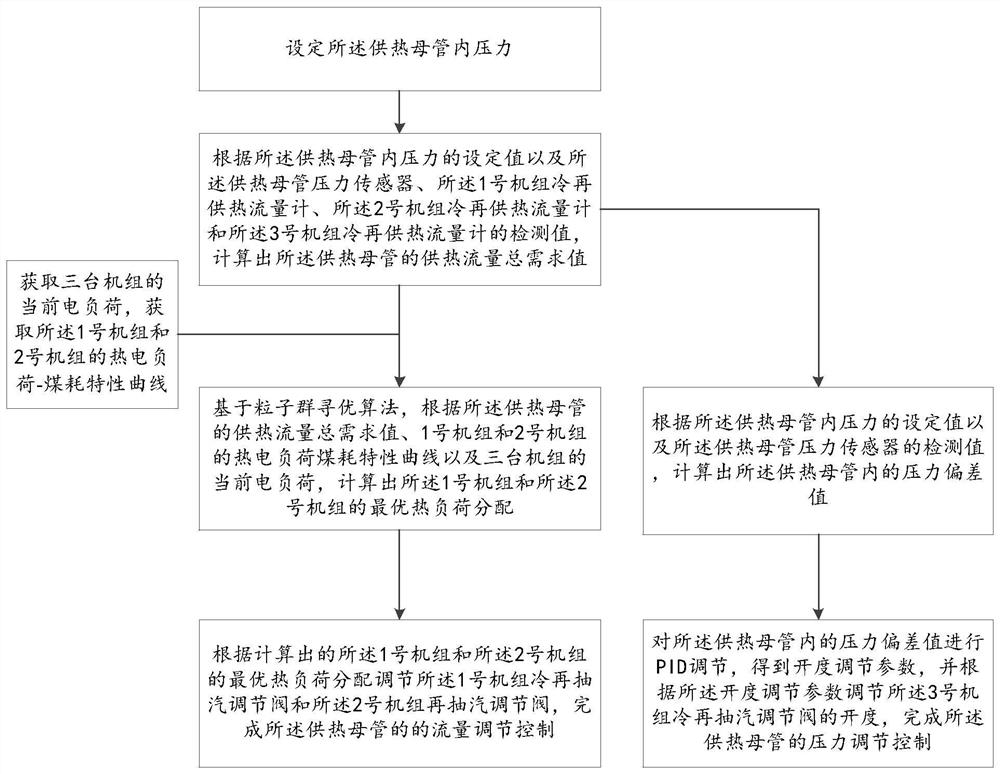

[0036] like figure 1 As shown in the figure, a combined flow and pressure control system for multiple cooling and reheating units includes No. 1 unit, No. 2 unit, No. 3 unit, a heating main pipe, a pressure setting module for the heating main pipe, and the flow rate of the heating main pipe. Demand calculation module, multi-unit actual generating power acquisition module, multi-unit flow scheduling module, limit speed limit module, deviation calculation module and PID control module;

[0037] The No. 1 unit is connected to the heating main pipe through the No. 1 pipeline, the No. 2 unit is connected to the heating main pipe through the No. 2 pipeline, and the No. 3 unit is connected to the heat supply through the No. 3 pipeline. The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com