Centrifugal compressor and impeller thereof

A centrifugal compressor and impeller technology, applied in the field of compressors, can solve problems such as unfavorable oil return of compressors, large heat transfer resistance of heat exchangers, and poor lubrication of compression-related components, so as to reduce the absolute Mach number and Effect of flow loss and increased reaction degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

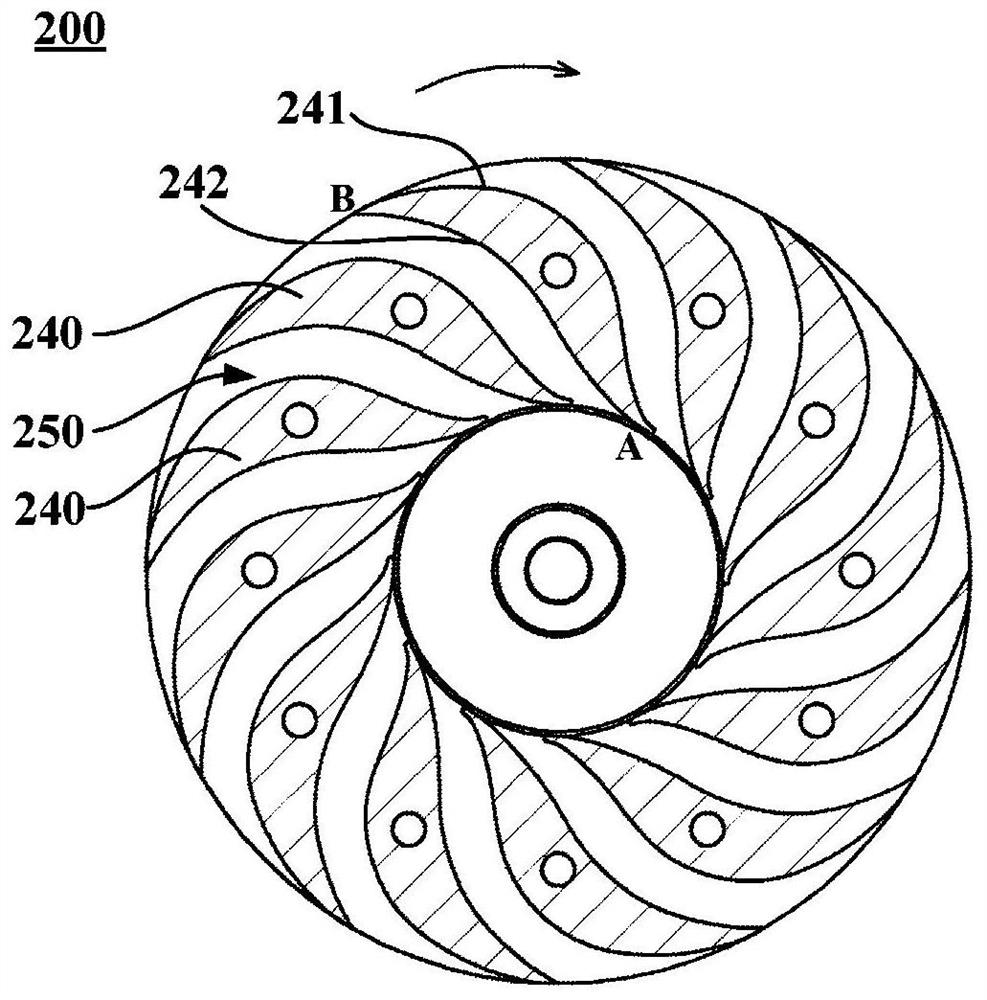

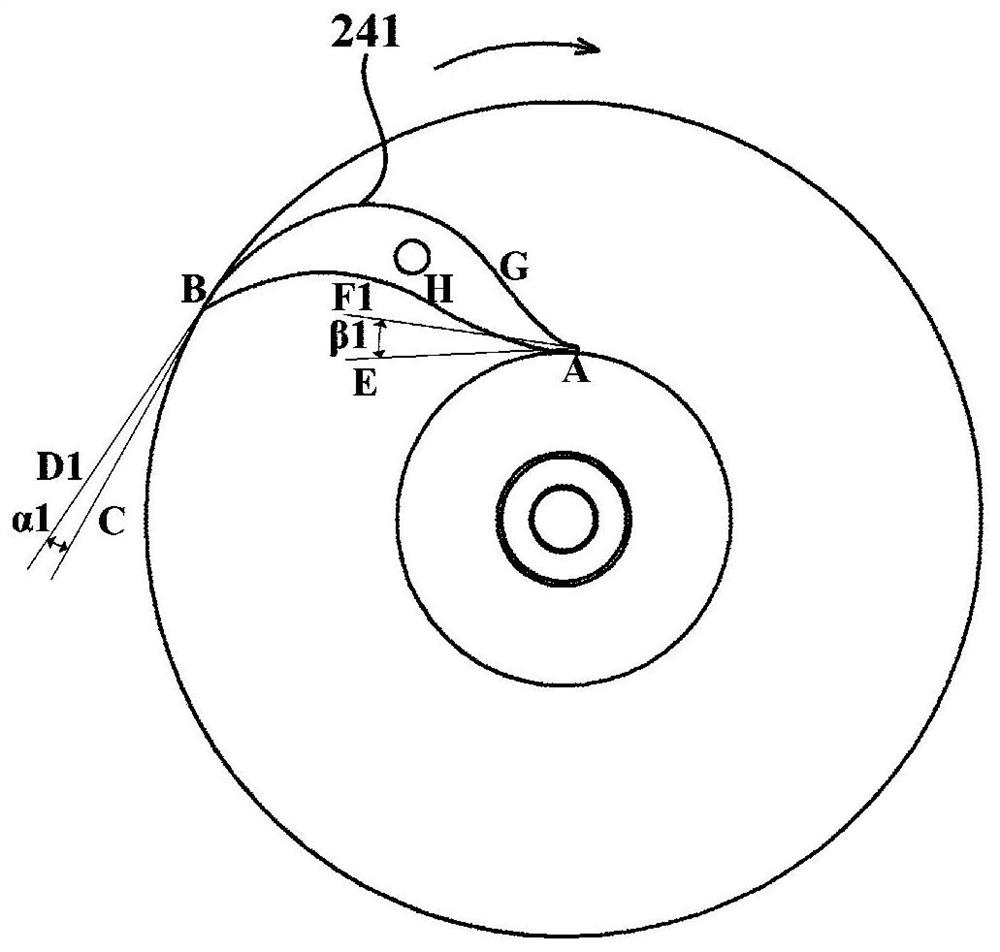

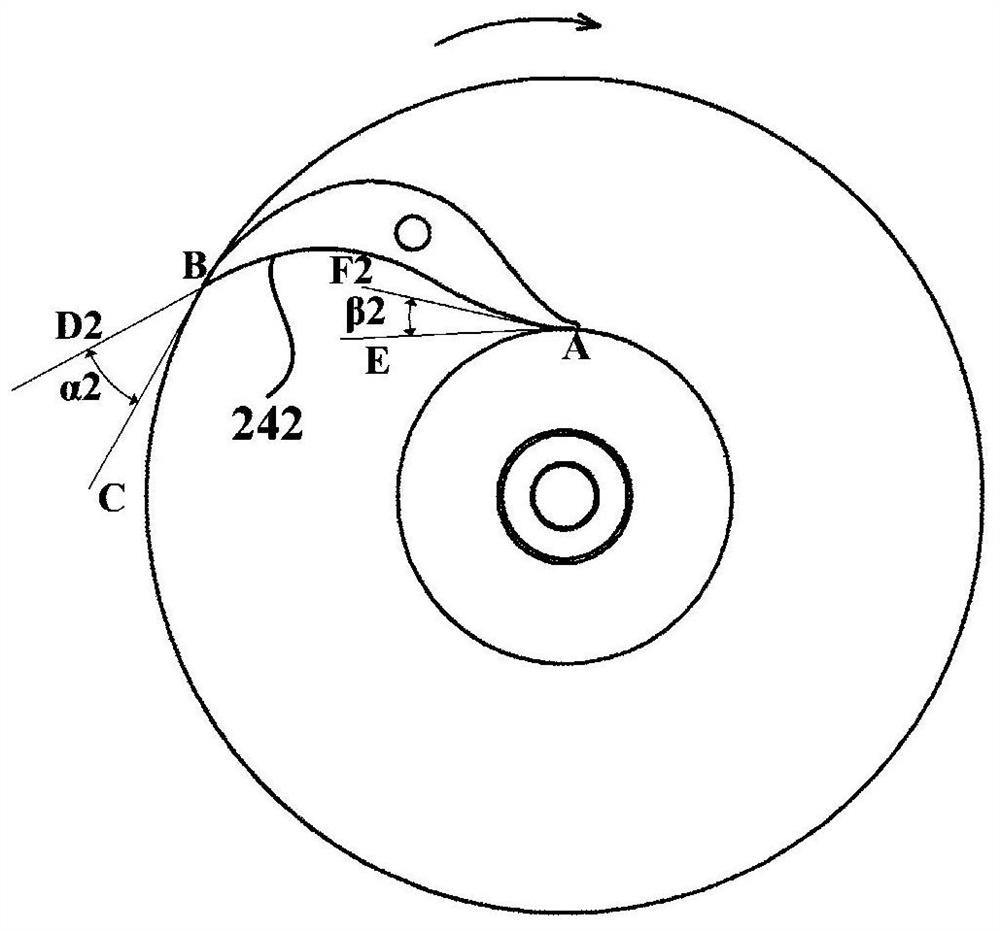

[0038] Refer below Figure 1 to Figure 12 The centrifugal compressor and the impeller 200 thereof according to the embodiment of the present invention will be described. In some figures, the x-axis is used to represent the axial direction of the impeller 200, which is also the axial direction of the motor 40 and its stator 41 and rotor 42; solid arrows are used to represent the airflow direction.

[0039] figure 1 is a schematic diagram of the profile of the impeller according to an embodiment of the present invention; figure 2 Yes figure 1 A schematic diagram of the installation angle of the pressure surface 241 of a blade 240 in the shown impeller 200; image 3 Yes figure 1 A schematic illustration of the mounting angle of the suction surface 242 of one of the blades 240 in the impeller shown.

[0040] The impeller 200 of the embodiment of the present invention is used in a centrifugal compressor, such as figure 1 As shown, the impeller 200 includes a plurality of bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com