Self-moving type tunnel dust removal equipment

A dust removal equipment, self-moving technology, applied in mining equipment, dust prevention, human health protection and other directions, can solve the problems of wide distribution of dust, waste of water resources, fan heating, etc., to improve work safety, protect health, The effect of avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

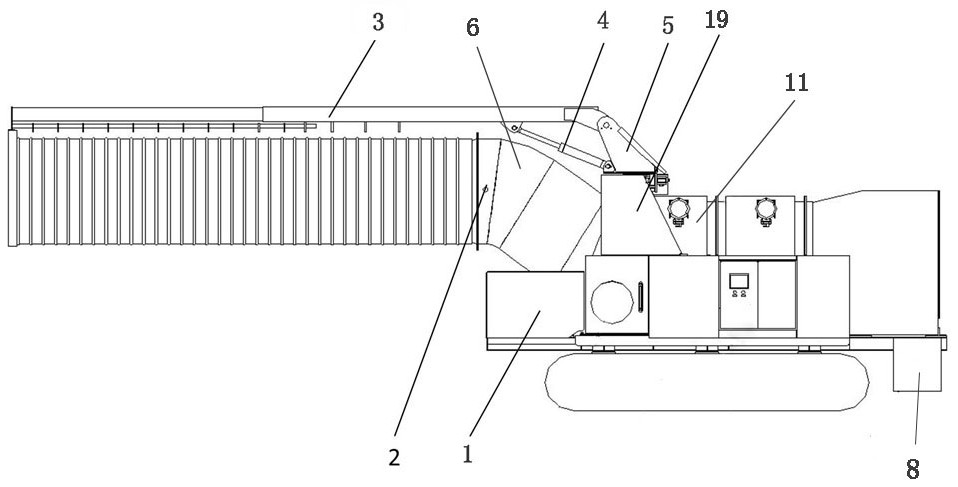

[0047] like Figures 1~7 As shown, a self-moving tunnel dust removal equipment includes a dust removal device, a traveling device, an air duct device and a sewage discharge device. The traveling device includes a carrier vehicle 1. The top of the carrier vehicle 1 is provided with an air duct device. One end is connected to the dust removal device, the dust removal device includes a fan 11, the sewage outlet of the dust removal device is connected to the sewage discharge device, and an intelligent control system is arranged between the dust removal device, the walking device, the air duct device and the sewage discharge device, and the air duct device includes The air duct 2 and the hanging device. The air duct 2 is fixed to the carrier vehicle 1 through the hanging device. The intelligent control system is used to control the hanging device to adjust the position of the air duct 2. The dust removal device is electrically connected to the intelligent control system. The device...

Embodiment 2

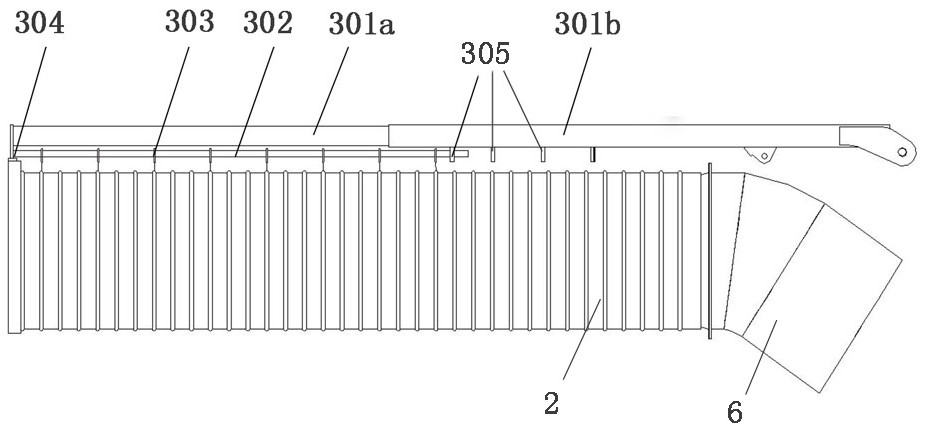

[0051] In combination with the above embodiment, the adjustment of the air duct 2 is optimized as follows Figure 2~4 shown:

[0052] The hanging device includes a telescopic mechanism 3, the telescopic mechanism 3 includes a telescopic rod 301, the telescopic rod 301 is a stepped column structure, and the telescopic rod 301 includes a large diameter end (marked as 301b in the figure) and a plurality of Small diameter end (marked as 301a in the figure), the large diameter end is sleeved outside the small diameter end, the small diameter end is slidably connected with the large diameter end, and the large diameter end and the small diameter end are circular, square or polygonal;

[0053] The lower side of the small diameter end of the telescopic rod 301 is provided with a hanging rod 302, the hanging rod 302 is a long round tube, and a plurality of hanging rings 303 are fixedly connected to the middle of the hanging rod 302 at an equal distance. A connecting ring 304 is arrang...

Embodiment 3

[0064] Based on Example 1, the dust removal mechanism is optimized as follows figure 1 , 6 and 7 as shown:

[0065] The dedusting device further includes a dedusting box, a spraying mechanism, a filtering mechanism and a dewatering mechanism are arranged inside the dedusting box, the nozzle ring is arranged at the position of the air inlet of the dedusting box, and the spraying mechanism includes a water tank and a nozzle, and the nozzle is arranged Inside the dust removal box body, the water tank is arranged outside the dust removal box body, a filter mechanism is arranged in the middle of the dust removal box body, and the filter mechanism includes a multi-layer filter screen;

[0066] The dehydration mechanism is arranged at the rear end of the dust removal box, and the dehydration mechanism includes an exhaust pipe, and the exhaust pipe and the dust box are an integrated structure;

[0067] The water tank and the spray head are connected through a water supply pipeline, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com