A detachable prestressed steel truss composite panel

A technology of prestressed steel bars and steel trusses, applied in the field of laminated board equipment, can solve problems such as large volume and difficult disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

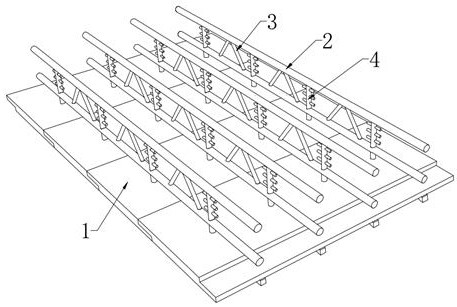

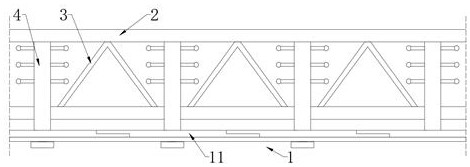

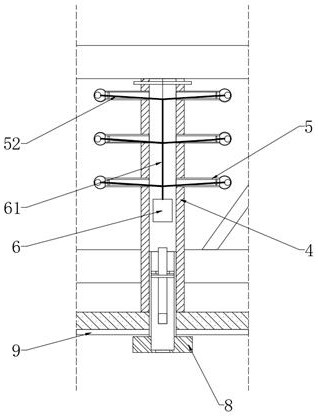

[0044] see Figure 1-9 , a detachable prestressed steel bar truss laminated board, including a template 1, a plurality of evenly distributed detection cylinders 4 are fixedly connected to the template 1, and two steel trusses 2 are fixedly connected between the multiple detection cylinders 4, two A plurality of keel steel bars 3 are fixedly connected between the steel bar trusses 2, a plurality of symmetrically arranged branch measuring cylinders 5 are fixedly connected to the detection cylinder 4, and a water permeable filter membrane 51 is fixedly connected to one end of the plurality of branch measuring cylinders 5 away from the detection cylinder 4, The inside of the water permeable filter membrane 51 is provided with a limited expansion ball 52, the inside of the branch measuring cylinder 5 is slidably connected with a movable plug 54, and the inside of the detection cylinder 4 is provided with a heavy pulling block 6, and the upper end of the heavy pulling block 6 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com