Efficient integrated prefabricated drainage pumping station and drainage method thereof

A technology for drainage pumping stations and drainage pumps, applied in chemical instruments and methods, drainage structures, water/sewage treatment, etc., which can solve the problems of slow drainage speed, limited pumping station space, weak water storage capacity, etc., and achieve improved drainage capacity , Increase the number of water pumps and increase the drainage speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

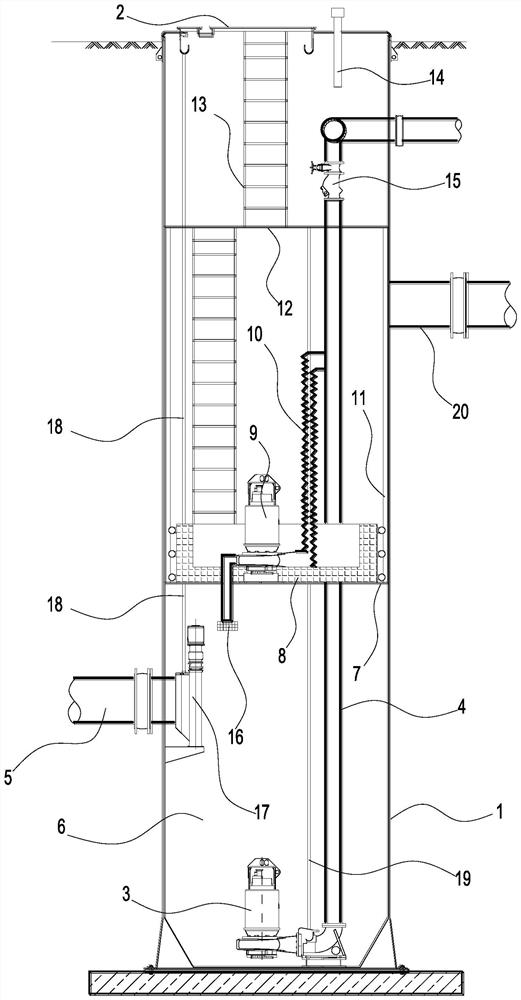

[0021] like figure 1 As shown, the high-efficiency integrated prefabricated drainage pump station of the present invention includes a well body 1 and a manhole cover 2, and the well body 1 is prefabricated in an integrated manner with concrete to facilitate construction. The well cover 2 covers the mouth of the well body 1 to prevent external sundries from falling into the well body 1 .

[0022] The lower part of the well body 1 is provided with a water storage cavity 6 for storing the water to be discharged. The side wall of the water storage cavity 6 is provided with a water inlet pipe 5, which is used to pass into the external accumulated water. The bottom is provided with a lower drainage pump 3, which can be a submersible sewage pump for drainage.

[0023] The top of the water storage cavity 6 is provided with a support platform 7 with a water pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com