Polyurethane adhesive main glue for compounding wall cloth, preparation method of polyurethane adhesive main glue and polyurethane adhesive

A technology of polyurethane adhesive and main glue, applied in the direction of polyurea/polyurethane adhesive, adhesive type, adhesive, etc. Wire and other problems, to achieve the effect of low cost, less glue wire, and short glue wire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

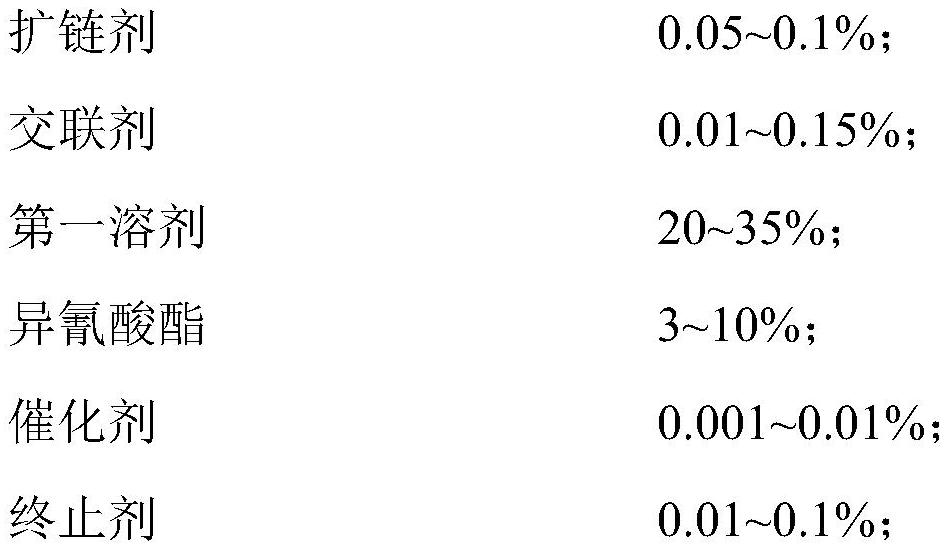

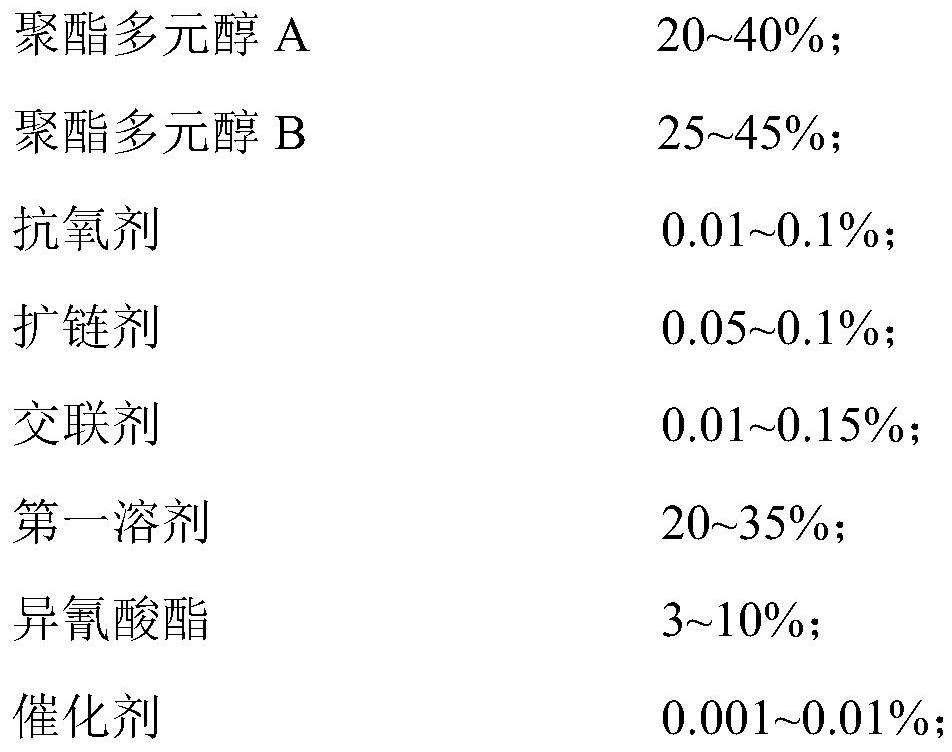

[0043] The present embodiment provides a two-liquid short wire polyurethane adhesive main adhesive for wall cloth composite, prepared by the following method:

[0044] Polyester polyol A with an average molecular weight of 3000 for 30 parts, polyester polyol B with an average molecular weight of 2500 for 35 parts, antioxidant 1010 for 0.1 parts, ethylene glycol for 0.1 parts, TMP for 0.05 parts were added to the reactor, turned on stirring, cooled to 55 °C, add DMC 15 parts, stirred for 30min, to ensure that the raw materials in the kettle have been completely stirred, maintain the reactor temperature of 55 °C, add TDI 5 parts. Heat up to 75 °C and stir for 1 h. Add 0.002 parts of the organic bismuth catalyst and heat up to 80 °C to continue the reaction. After gardner reaches W viscosity, turn off heating, add DMC 15 parts, 1,3-BG 0.1 parts, stir for 1 h. Packaged and discharged, sealed and stored.

[0045] In this example, the polyester polyol A is polyphthalic anhydride glycol ...

Embodiment 2

[0048] The present embodiment provides a two-liquid short wire polyurethane adhesive main adhesive for wall cloth composite, prepared by the following method:

[0049]Polyester polyol A with an average molecular weight of 2000 for 25 parts, polyester polyol B with an average molecular weight of 2500 for 2500 parts, antioxidant 1010 for 0.1 parts, ethylene glycol for 0.1 parts, TMP for 0.1 parts, open stirring, cool down to 55 °C, add DMC 15 parts, stir for 30 minutes, ensure that the raw materials in the kettle have been completely stirred, keep the reactor temperature at 55 °C, add TDI 5 parts. Heat up to 75 °C and stir for 1 h. Add 0.002 parts of the organic bismuth catalyst and heat up to 80 °C to continue the reaction. After gardner reaches W viscosity, turn off heating, add DMC 15 parts, 1,3-BG 0.1 parts, stir for 1 h. Packaged and discharged, sealed and stored.

[0050] In the present example, the polyester polyol A used, polyester polyol B used raw materials and the ratio o...

Embodiment 3

[0052] The present embodiment provides a two-liquid short wire polyurethane adhesive main adhesive for wall cloth composite, prepared by the following method:

[0053] Polyester polyol A with an average molecular weight of 2500 for 20 parts, polyester polyol B with an average molecular weight of 3000 for 45 parts, antioxidant 1010 for 0.1 parts, ethylene glycol for 0.1 parts, TMP for 0.15 parts added to the reactor, start stirring, cool down to 55 °C, add DMC 15 parts, stir for 30min, ensure that the raw materials in the kettle have been completely mixed, keep the reactor temperature at 55 °C, and add TDI 5 parts. Heat up to 75 °C and stir for 1 h. Add 0.002 parts of the organic bismuth catalyst and heat up to 80 °C to continue the reaction. After gardner reaches W viscosity, turn off heating, add DMC 15 parts, 1,3-BG 0.1 parts, stir for 1 h. Packaged and discharged, sealed and stored.

[0054] In the present example, the polyester polyol A used, polyester polyol B used raw materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com