Oxygen purification and regeneration equipment in multi-tower molecular sieve oxygen generation system and use method of oxygen purification and regeneration equipment

A technology of oxygen production system and regeneration equipment, which is applied in the field of oxygen production system, can solve the problems of poor use effect and inability to collect oxygen, and achieve the effect of increasing oxygen concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

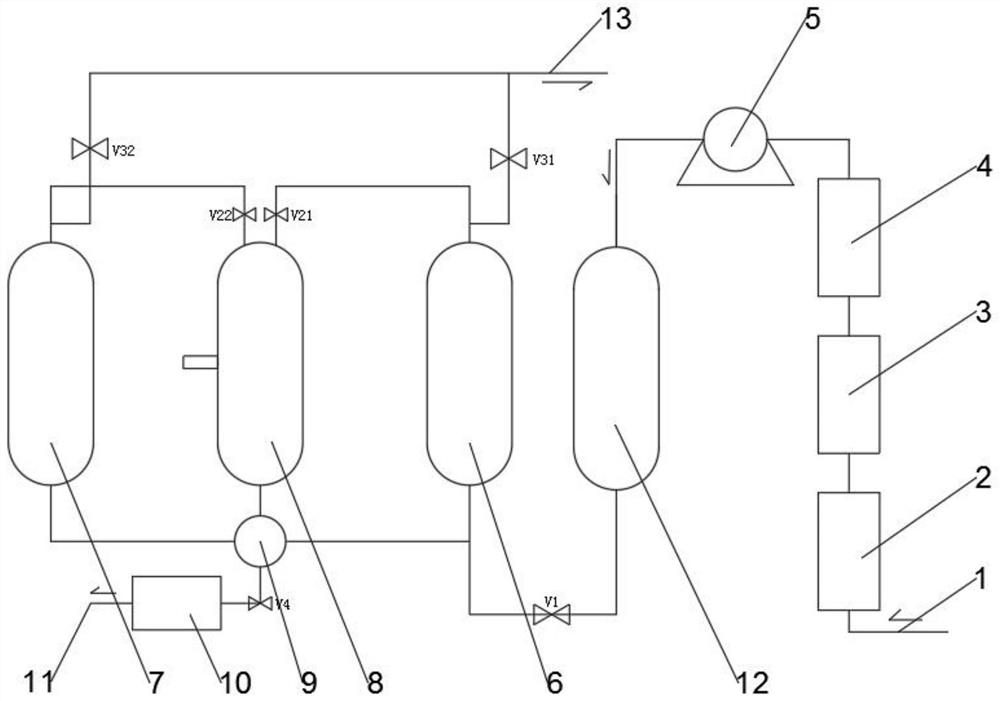

[0034] see figure 1 In the embodiment of the present invention, the oxygen purification and regeneration equipment in the multi-tower molecular sieve oxygen production system and its use method are described with two towers instead of multiple adsorption towers. The two-tower structure includes at least two adsorption towers filled with zeolite molecular sieves. 1 and adsorption tower two 7, the air inlet of adsorption tower one 6 communicates with pressure equalizing tower 12 through solenoid valve V1, and the air inlet of pressure equalizing tower 12 is connected with compressor 5, secondary filter 4, dehumidifier 3 and one in turn. Stage filter 2, the air inlet of the first stage filter 2 is communicated with the air inlet pipe 1, the air inlets of the adsorption tower one 6 and the adsorption tower two 7 are all connected with the rotary valve 9, and the rotary valve 9 is communicated with the bacterial filter 10 air inlet and The air outlet of the oxygen buffer tower 8 is...

Embodiment 2

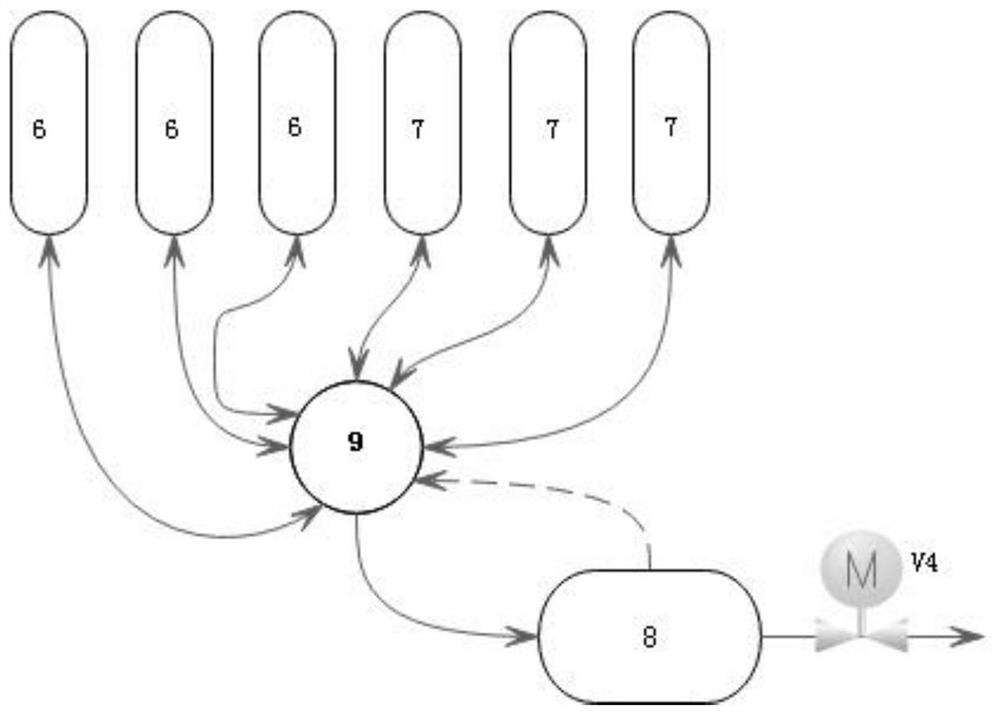

[0039] see figure 2 The difference between the embodiment of the present invention and the first embodiment is that an intelligent rotary valve is used instead of a solenoid valve or a one-way valve, an oxygen buffer tank is provided at the oxygen outlet, and 4-6 adsorption towers are provided, each with the intelligent rotary valve. The valve is connected and set separately, and the oxygen in the oxygen buffer tower 8 is transported to different adsorption towers through the intelligent rotary valve for secondary purification, so that the oxygen concentration can be rapidly increased.

[0040] Using method of the present invention, the specific implementation process is as follows:

[0041] S1: The air is extracted by the compressor 5, passes through the primary filter 2, the dehumidifier 3, the secondary filter 4 in turn, and finally enters the pressure equalizing tower 12, the solenoid valves V1 and V21 are opened, and the high-pressure air enters the intelligent rotary va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com