High-strength cantilever bearing beam and multi-angle layer structure pulling and winding equipment and method

A load-bearing structure and high-strength technology, which is applied in the field of high-strength cantilever load-bearing beams and multi-angle layer structure winding equipment, can solve the problems of single winding method and product performance that cannot meet the needs of heavy industry, and achieve high safety and reduce manual handling. , the effect of less energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

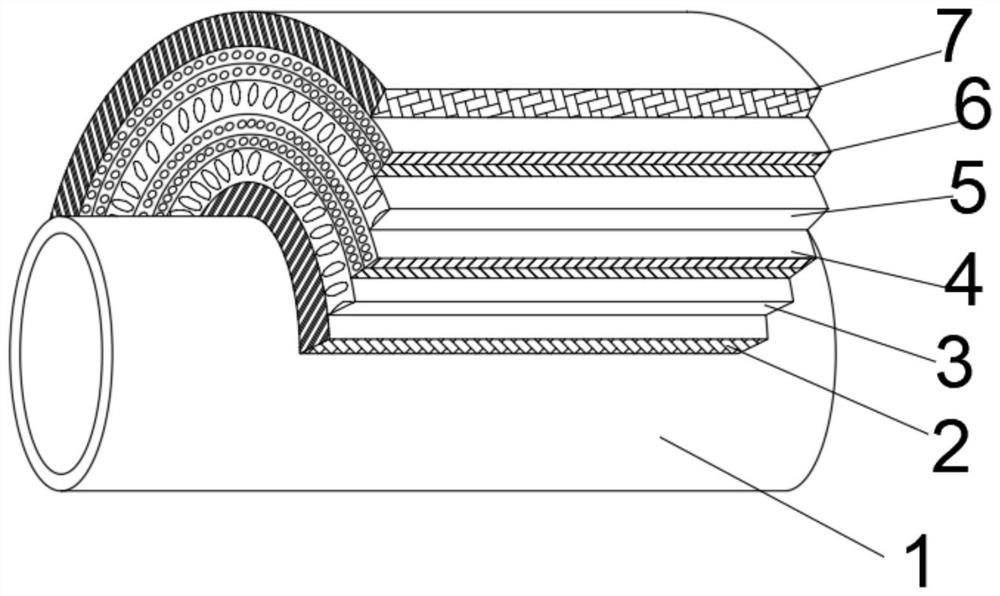

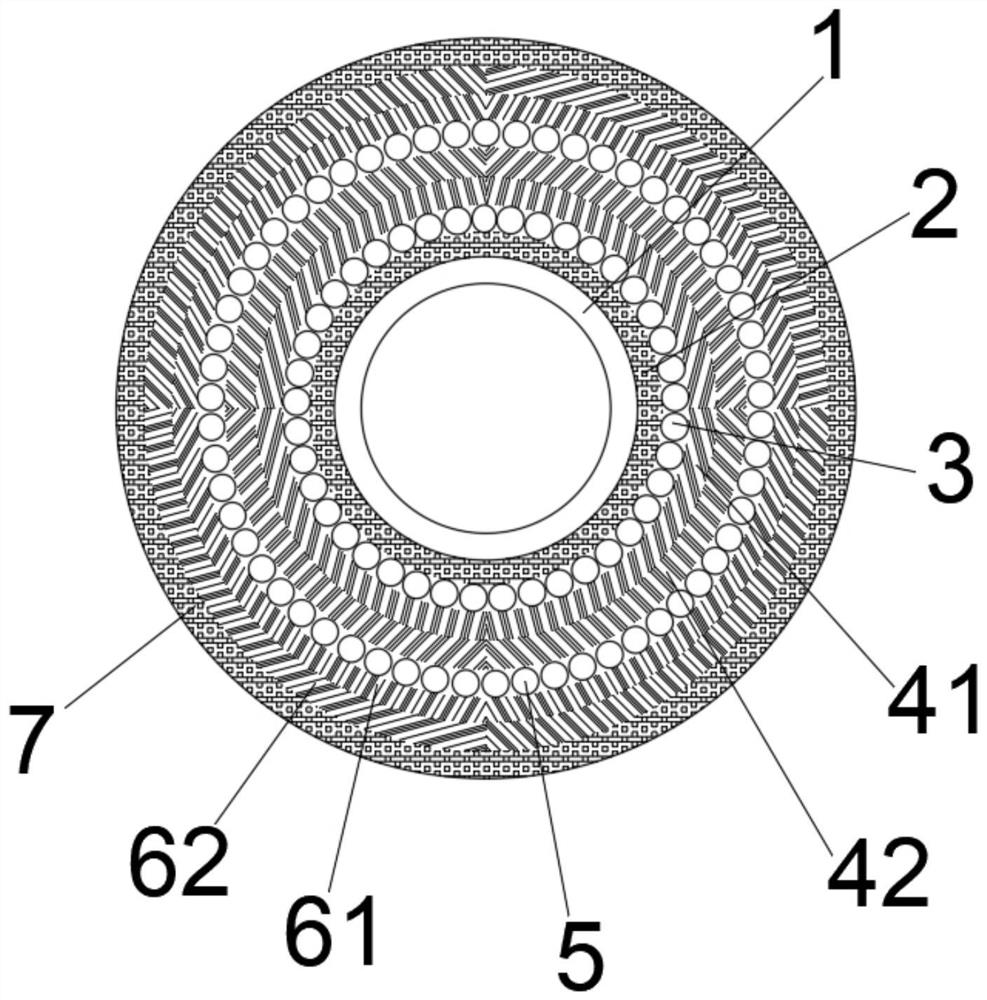

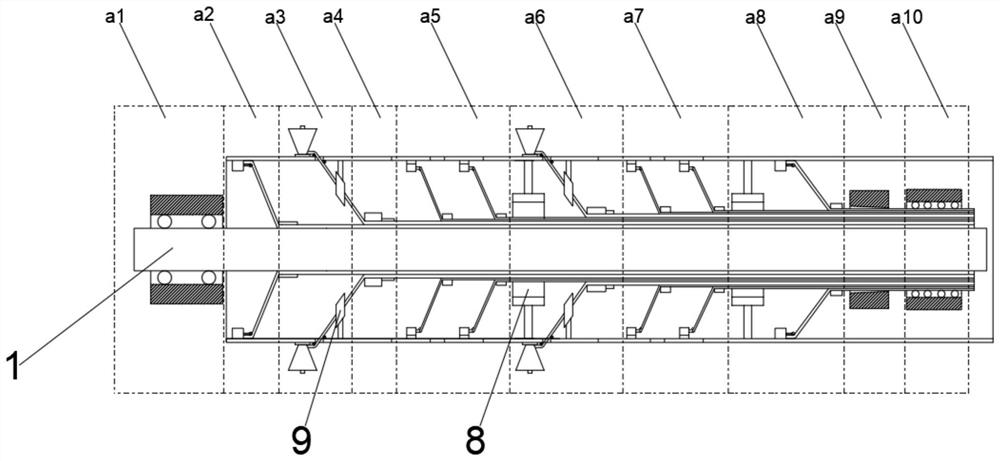

[0036] like Figure 1 to Figure 3 As shown, a high-strength cantilever bearing beam includes a bearing tube 1 and several layers of bearing structures compounded on the outer circumference of the bearing tube 1. The bearing tube 1 includes a square tube and a round tube, and the material includes an epoxy resin-based carbon fiber reinforced tube, The load-bearing structure includes braided layers arranged on both sides of the inner and outer sides and a reinforcing layer compounded between the two braided layers, and the reinforcing layer includes several anti-bending layers and anti-torsion layers formed by alternately compounding.

[0037] In this embodiment, the braided layer includes an adhesive layer 2 that is compositely and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com