Cutting device and cutting method for new material production

A technology of cutting device and cutting method, which is applied in the direction of stone processing equipment, stone processing tools, work accessories, etc., and can solve the problems of wasting human resources and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

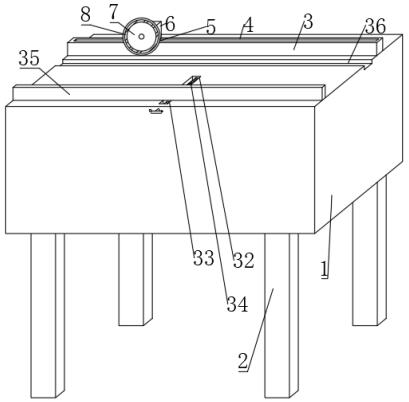

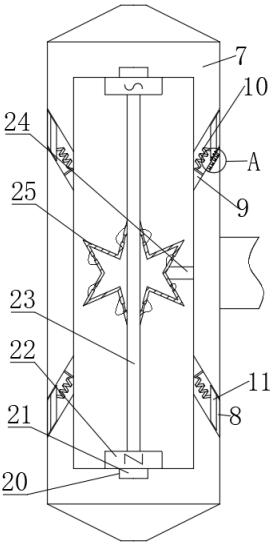

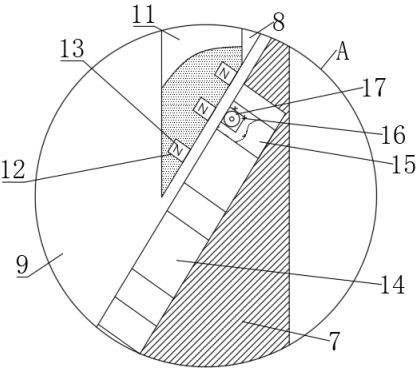

[0030] Reference Figure 1-9, a new material production with cutting device and cutting method, including cutting table 1, cutting table 1 bottom two sides symmetrically fixed by bolts with multiple pillars 2, cutting table 1 top by bolt fixed plate 3, fixing plate 3 top nested fixed with sliding rail 4, sliding rail 4 inside the sliding rail 4, electric sliding slider 5 top through bolt fixed motor 6, motor 6 output shaft connected to the disc saw blade 7, disc saw blade 7 at both ends are opened with installation grooves 9, installation groove 9 main view section set to round, Mounting groove 9 cross-section is provided as a parallelogram, the bottom of the inner wall of the mounting groove 9 is bolted with a plurality of ring array distribution of the first spring 10, the front end of multiple first springs 10 is bolted to the same mounting ring 11, the mounting ring 11 is provided with a matching grinding blade 8, the outer wall of the mounting ring 11 is opened with multiple s...

Embodiment 2

[0039]Reference Figure 1-9 , a new material production with cutting device and cutting method, the method comprises the following steps:

[0040] S1, preparation - the grinding blade 8 on the rod 41 into the jack 37, the third spring 39 to promote the card ball 40 and the arc of the docking groove 43 card connection, so that the rod 41 is fixed, so that the grinding blade 8 replacement process is convenient, and set with rubber sheet 44, you can effectively improve the fixing effect of the plug rod 41, further set with a triangular resistance increase groove 45, you can improve the roughness of the surface of the rubber sheet 44, increase static friction, thereby further improving the fixing effect of the plug rod 41;

[0041] S2, fixed - the ceramic plate to be processed is placed between the plywood 35 and the fixed plate 3, turn the handle, drive the screw 34 to rotate, so that the slider 33 drives the splint 35 to move to the rear end, until the ceramic plate clamped and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com