Medical molecular sieve oxygen generation system

An oxygen production system and molecular sieve technology, applied in the field of medical devices, can solve the problems of high adsorption capacity and nitrogen-oxygen separation coefficient, and achieve the effect of reducing energy consumption and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A medical molecular sieve oxygen system, comprising a compressor, an air tank and at least two adsorption towers, the adsorption tower is filled with oxygen-making molecular sieves, the adsorption tower is provided with a temperature sensor inside, the air tank is provided with a pressure sensor, the compressor is connected to the temperature sensor and the pressure sensor signal by the processor respectively;

[0035] Wherein, the temperature sensor and the pressure sensor respectively monitor the internal temperature of the adsorption tower and the internal pressure of the air tank, and transmit the real-time temperature signal and pressure signal to the processor, the temperature signal and pressure signal are processed by the processor, the processor outputs a control signal and transmits it to the compressor, thereby adjusting the intake pressure of the compressor;

[0036] The preparation method of the oxygen molecule sieve comprises the following steps:

[0037](1) A...

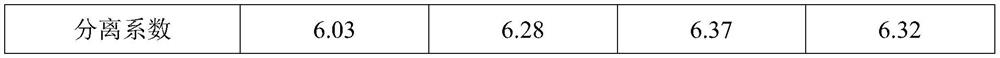

Embodiment 2

[0043] With Example 1, the difference is that the preparation method of the oxygen-making molecular sieve further comprises metal ion exchange and secondary crystallization, the exchange method of the metal ions is:

[0044] The oxygen-making molecular sieve was added to the re-distilled water equivalent to 20 times its mass, a water-soluble lithium salt was added under stirring conditions, the lithium content in the lithium salt and the mass ratio of the oxygen-making molecular sieve was 1:5, after fully stirring and mixing evenly, the oxygen-making molecular sieve was exchanged for 10h at a temperature of 180 ° C, the oxygen-making molecular sieve was filtered out, an exchange was completed, the exchange was repeated 3 times, and after the exchange was completed, it was washed with re-distilled water and dried;

[0045] The secondary crystallization is specifically:

[0046] The sodium hydroxide solution with a concentration of 0.5mol / L was prepared with re-distilled water, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com